I am going to be going through my 93 ranger and giving it a refresh. I bought the truck in late 2004. Other then a rancho lift kt it was an all stock stripped truck with a 4.0 manual trans and tcase. No AC cruise or power windows. The perfect basic wheeling rig.

Here are the specs of how the truck currently sat before this refresh.

4.0V6 all stock

Stock 5 speed

d.d. machine duel case setup with manual 1350 front and 1354 rear.

Front axle is a 1984 Jeep wagonner dana 44 converted to 5 on 5.5 bolt pattern 4.88 gears and an Aussie locker

Three link front suspension using 8" skyjacker TJ springs.

Rear axle is a 1992 explorer 8.8 4.88 gears and welded spider gears.

63" Chevy springs with a bellteck shackle.

BroncoII tank behind the rear axle

Warn 9.5 XP winch behind the front grill.

Interior roll cage

37" MTR on 17" steel rims

Untitled by dresselhausfc, on Flickr

I took the truck down to King of The Hammers and few years ago and did some wheeling and managed to crush the bed good. Broke both front hubs and all 4 front axles, bent the rear driveshaft and ripped a shock mount off. Due to life getting in the way it sat on the trailer for 18 months before I even touched it again. Now I plan to give the truck some love and get it back on the trials again.

Here are the specs of how the truck currently sat before this refresh.

4.0V6 all stock

Stock 5 speed

d.d. machine duel case setup with manual 1350 front and 1354 rear.

Front axle is a 1984 Jeep wagonner dana 44 converted to 5 on 5.5 bolt pattern 4.88 gears and an Aussie locker

Three link front suspension using 8" skyjacker TJ springs.

Rear axle is a 1992 explorer 8.8 4.88 gears and welded spider gears.

63" Chevy springs with a bellteck shackle.

BroncoII tank behind the rear axle

Warn 9.5 XP winch behind the front grill.

Interior roll cage

37" MTR on 17" steel rims

Untitled by dresselhausfc, on Flickr

I took the truck down to King of The Hammers and few years ago and did some wheeling and managed to crush the bed good. Broke both front hubs and all 4 front axles, bent the rear driveshaft and ripped a shock mount off. Due to life getting in the way it sat on the trailer for 18 months before I even touched it again. Now I plan to give the truck some love and get it back on the trials again.

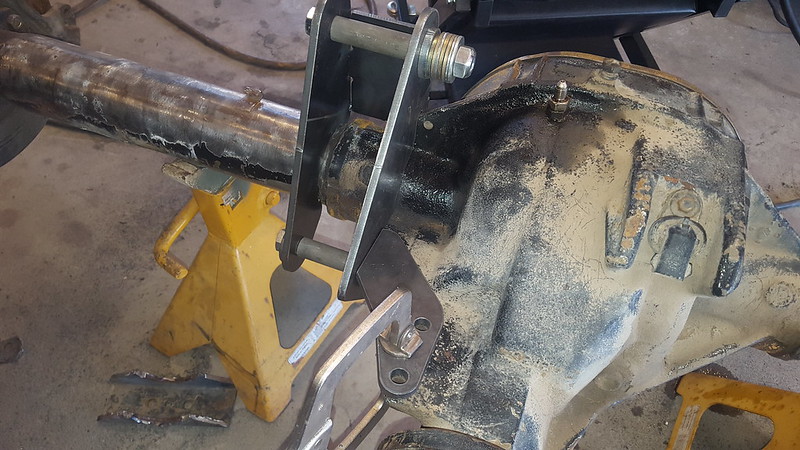

20170522_124156

20170522_124156 20170523_105257

20170523_105257 20170523_111632

20170523_111632 20170523_113022

20170523_113022 20170523_113043

20170523_113043 20170523_113032

20170523_113032 20170523_192349

20170523_192349 20170523_192401

20170523_192401 20170524_092049

20170524_092049 20170524_092002

20170524_092002 20170524_113632

20170524_113632 20170524_115525

20170524_115525 IMG_0817

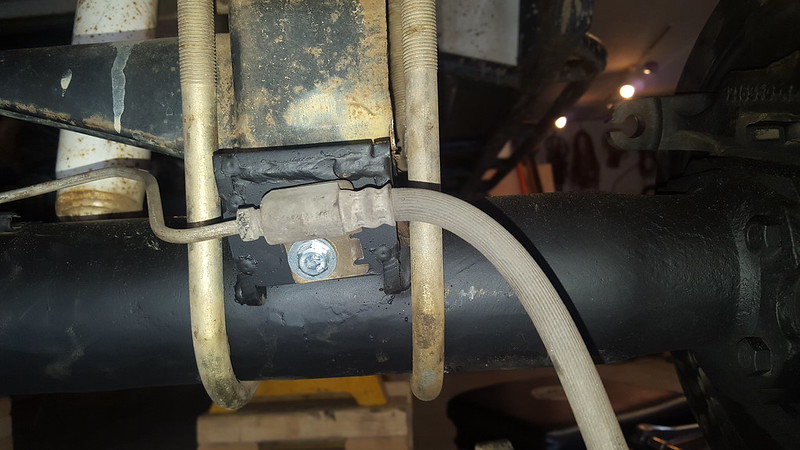

IMG_0817 IMG_0851

IMG_0851 IMG_0852

IMG_0852 IMG_0835

IMG_0835 IMG_0837

IMG_0837 20170703_140024

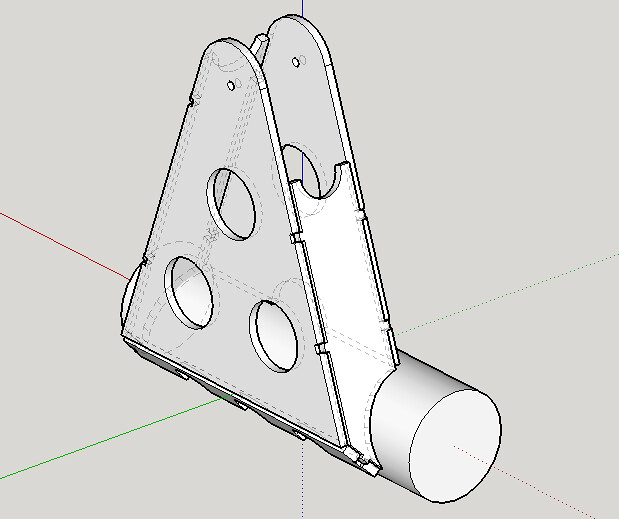

20170703_140024 bracket2

bracket2