well figured i would start a new thread.just a quick background.did the whole build on my explorer but built it using stock head gaskets and head bolts.did it really as a safety net and i just couldnt afford head studs at the time.well to say the least i blew the head gaskets off from it wile i was in the mountains on a forum trip about two years later.

i picked up a 1994 ranger,its got the 4.0 OHV and is a 5 speed 2wd.the plan is to pull the motor out of the explorer and rebuild it.

this thread will basically cover the rebuild and build up of the new ranger.it will basically end up as a street race truck.ive named it Rudy

so let the fun begin.

so let the fun begin.

UPDATE

new motor specs

BORE: 4" JE asymmetrical pistons (custom over bore)

RODS: 6.058 Manley (longer rod)

VALVES: IN-1.8 EX-1.5 Manley heavy duty (.150 over)

Transmission:T5 hybrid from a 2006 Mustang and 93 Fox

HEADS: 93TM HEAVILY ported with custom brass guides and copper gaskets/O-ringed with ARP studs

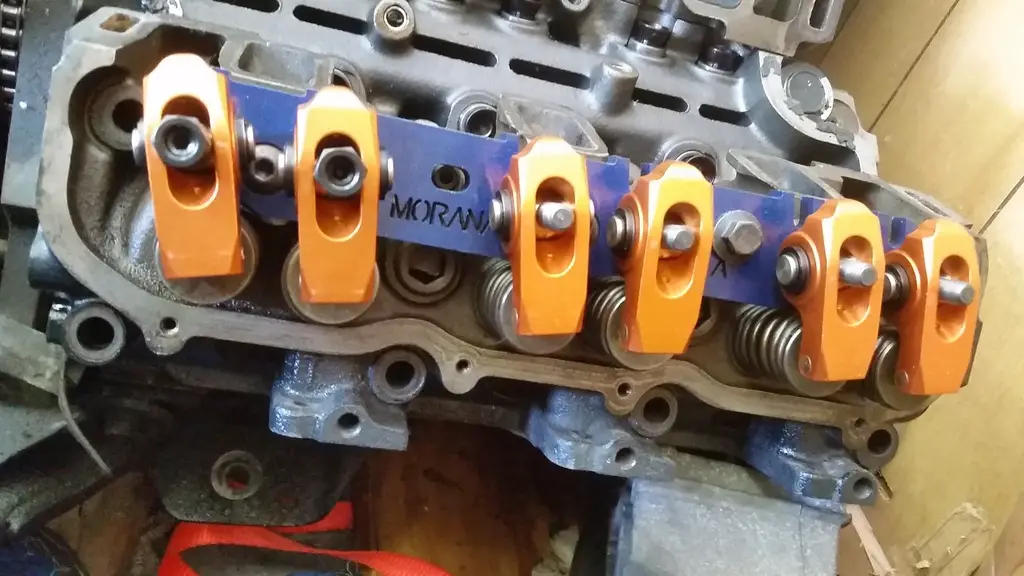

CAM: 422 Comp cams with 988 springs and Toms custom lifters,push rods and 1.7 roller rockers

Complete blueprint and balanced internals

GM M90 supercharged with one 1" intercooler plates with ASP 8 rib belt conversion. .

pushing 16 lbs of boost with small shot of NOS

Running on E50

Dyno tuned by Dyno Tune Performance outa Virginia using SCT

old thread and pic

3800 M90 Build

ported and polished gm 3800 gen 2 m90

Water to air intercooled

port matched 76mm inlet and intake tube

mustang 75mm race tb

90mm maf

36lb injectors

255 fuel pump

sct 5bank dyno tuned

2.7" pulley 10lbs of boost!!

and the new 1994 ranger 4.0 OHV 5 speed 2WD with 115,000 miles on it.o and i only paid $1,000 for it:shifty_ey

RUDY

i picked up a 1994 ranger,its got the 4.0 OHV and is a 5 speed 2wd.the plan is to pull the motor out of the explorer and rebuild it.

this thread will basically cover the rebuild and build up of the new ranger.it will basically end up as a street race truck.ive named it Rudy

UPDATE

new motor specs

BORE: 4" JE asymmetrical pistons (custom over bore)

RODS: 6.058 Manley (longer rod)

VALVES: IN-1.8 EX-1.5 Manley heavy duty (.150 over)

Transmission:T5 hybrid from a 2006 Mustang and 93 Fox

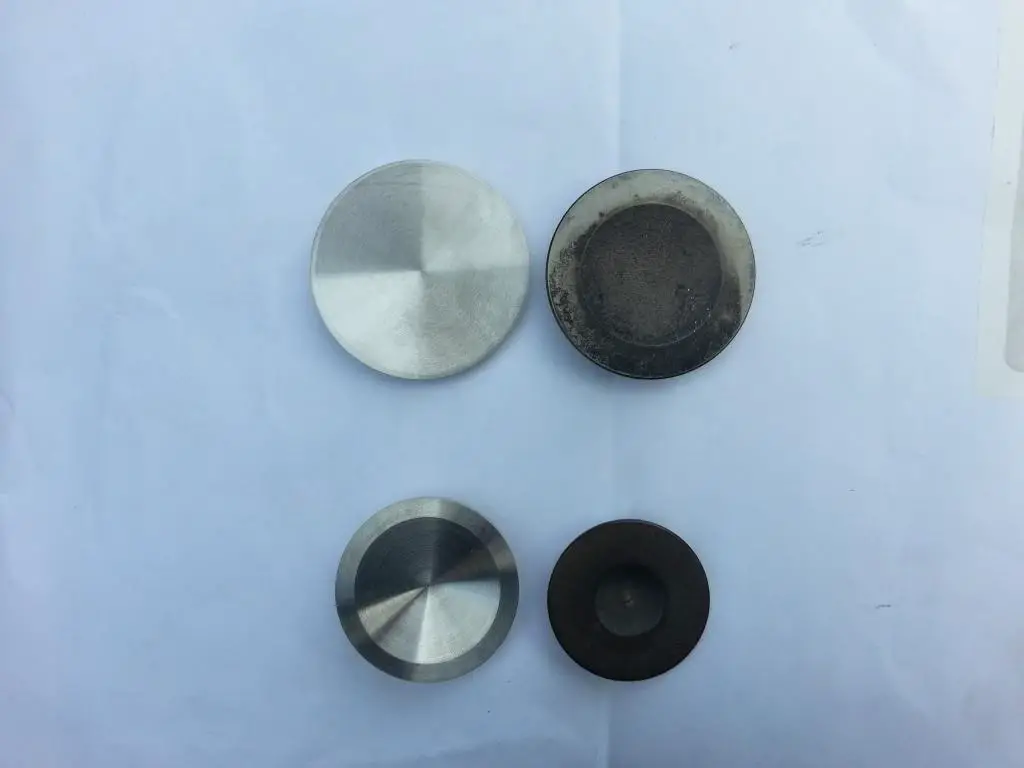

HEADS: 93TM HEAVILY ported with custom brass guides and copper gaskets/O-ringed with ARP studs

CAM: 422 Comp cams with 988 springs and Toms custom lifters,push rods and 1.7 roller rockers

Complete blueprint and balanced internals

GM M90 supercharged with one 1" intercooler plates with ASP 8 rib belt conversion. .

pushing 16 lbs of boost with small shot of NOS

Running on E50

Dyno tuned by Dyno Tune Performance outa Virginia using SCT

old thread and pic

3800 M90 Build

ported and polished gm 3800 gen 2 m90

Water to air intercooled

port matched 76mm inlet and intake tube

mustang 75mm race tb

90mm maf

36lb injectors

255 fuel pump

sct 5bank dyno tuned

2.7" pulley 10lbs of boost!!

and the new 1994 ranger 4.0 OHV 5 speed 2WD with 115,000 miles on it.o and i only paid $1,000 for it:shifty_ey

RUDY