Hello Explorer Fans.

I have been on the forums for some time and have extensively read many threads. I have enjoyed the forums so far. Now I have a question of opinion for you all.

I currently own 97' V6 SOHC Sport and I love it. I was going to SAS it, but Id rather do it to a V8 Explorer, plus, manual TC's are readily available for the swap.

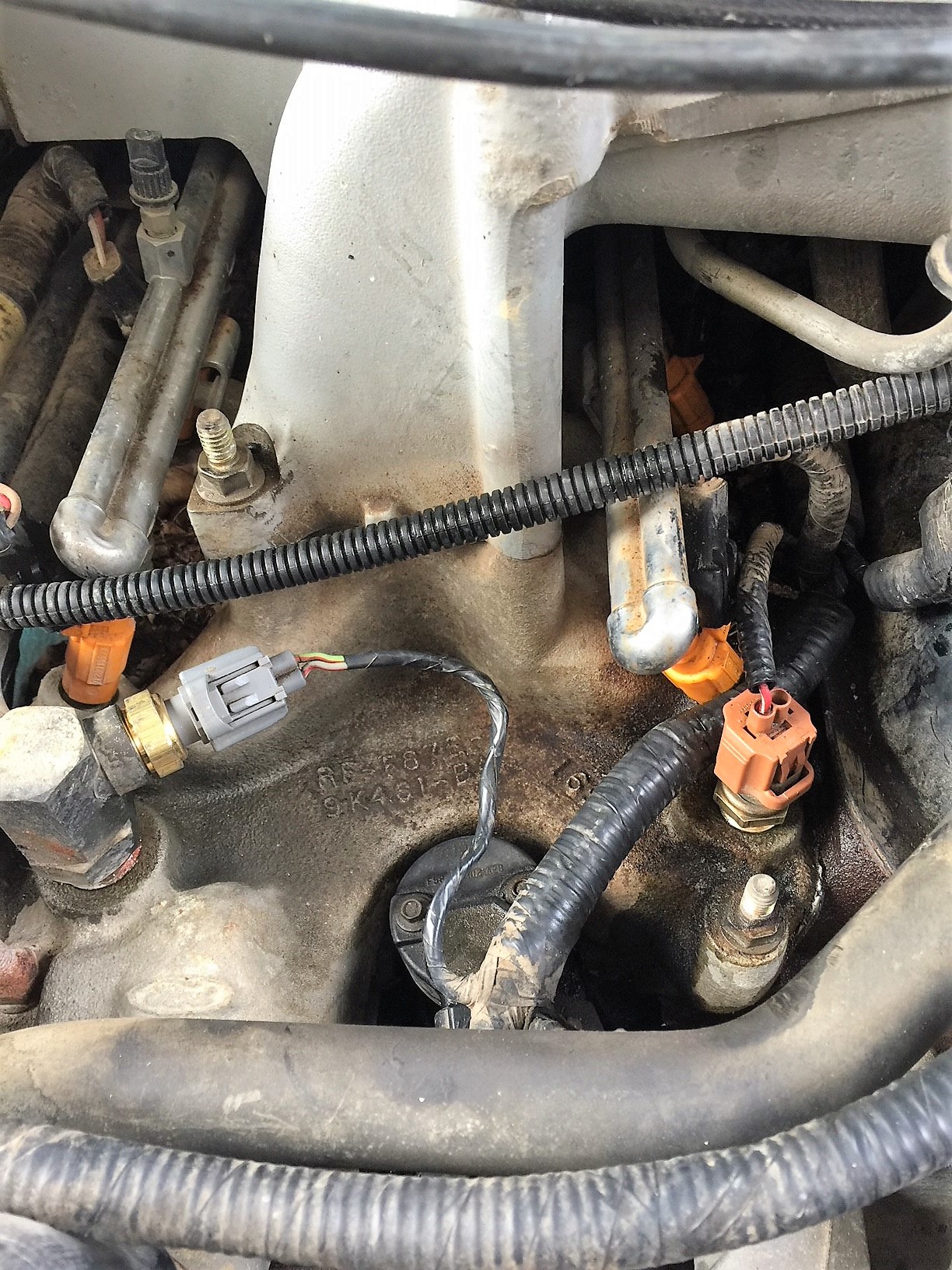

To get to the point, I'm looking at a 97' 5.0 AWD Explorer (166,000 miles) (for a few hundred bucks). It's a solid vehicle, straight but its flashing a few codes. I looked up the codes here on the forums and it appears to be a "simple" fix. It idles well, but has an obvious 'lumpiness' to it. When you accelerate under load, you can sort of hear and feel it. The codes I got were P1132 - Lack of Oxygen Sensor indicates Rich and P1131 - Lack of Heater Oxygen Sensor indicates Lean. Both appear to be O2 sensor issues which may not be that big a deal. The trans seems to shift well with no obvious issues.

I'm very mechanical in nature (I work on my own cars/trucks) and fabrication of all I want to do...is what I do.

I just wanted a few opinions on the success of fixing this issue and any potential things I should look for before i pull the trigger and pick this thing up.

Thanks everyone.

I have been on the forums for some time and have extensively read many threads. I have enjoyed the forums so far. Now I have a question of opinion for you all.

I currently own 97' V6 SOHC Sport and I love it. I was going to SAS it, but Id rather do it to a V8 Explorer, plus, manual TC's are readily available for the swap.

To get to the point, I'm looking at a 97' 5.0 AWD Explorer (166,000 miles) (for a few hundred bucks). It's a solid vehicle, straight but its flashing a few codes. I looked up the codes here on the forums and it appears to be a "simple" fix. It idles well, but has an obvious 'lumpiness' to it. When you accelerate under load, you can sort of hear and feel it. The codes I got were P1132 - Lack of Oxygen Sensor indicates Rich and P1131 - Lack of Heater Oxygen Sensor indicates Lean. Both appear to be O2 sensor issues which may not be that big a deal. The trans seems to shift well with no obvious issues.

I'm very mechanical in nature (I work on my own cars/trucks) and fabrication of all I want to do...is what I do.

I just wanted a few opinions on the success of fixing this issue and any potential things I should look for before i pull the trigger and pick this thing up.

Thanks everyone.

) thinking of each aspect of the system to ensure I didn't overlook anything...Im telling you, i checked everything next to pulling the box and cutting it open!....Then it hit me - the only thing it HAS TO BE is maybe a rodent built a nest in the box (remember I pulled a ton of acorns from the fan area when I got it)...there wasn't anything flying out of the vents...but hey, what the heck....its got to be the only reason why air was not moving in the box.

) thinking of each aspect of the system to ensure I didn't overlook anything...Im telling you, i checked everything next to pulling the box and cutting it open!....Then it hit me - the only thing it HAS TO BE is maybe a rodent built a nest in the box (remember I pulled a ton of acorns from the fan area when I got it)...there wasn't anything flying out of the vents...but hey, what the heck....its got to be the only reason why air was not moving in the box.