Paul Fithian

Elite Explorer

- Joined

- October 12, 2016

- Messages

- 336

- Reaction score

- 106

- City, State

- Long Beach, IN

- Year, Model & Trim Level

- 2007 Job 1 RWD V8 Limited

Thanks to the great information posted in this thread, http://www.explorerforum.com/forums/index.php?threads/5r55e-valve-body-rebuild-diary.140987/ , I had the confidence to dive into my transmission on a recently acquired 2001 Sport Trac with 258,000 miles. Runs great, transmission shifts well, but it did have delayed reverse engagement. No funny stuff in the fluid either. It appears to be original, with non-bonded gasket separator plate.

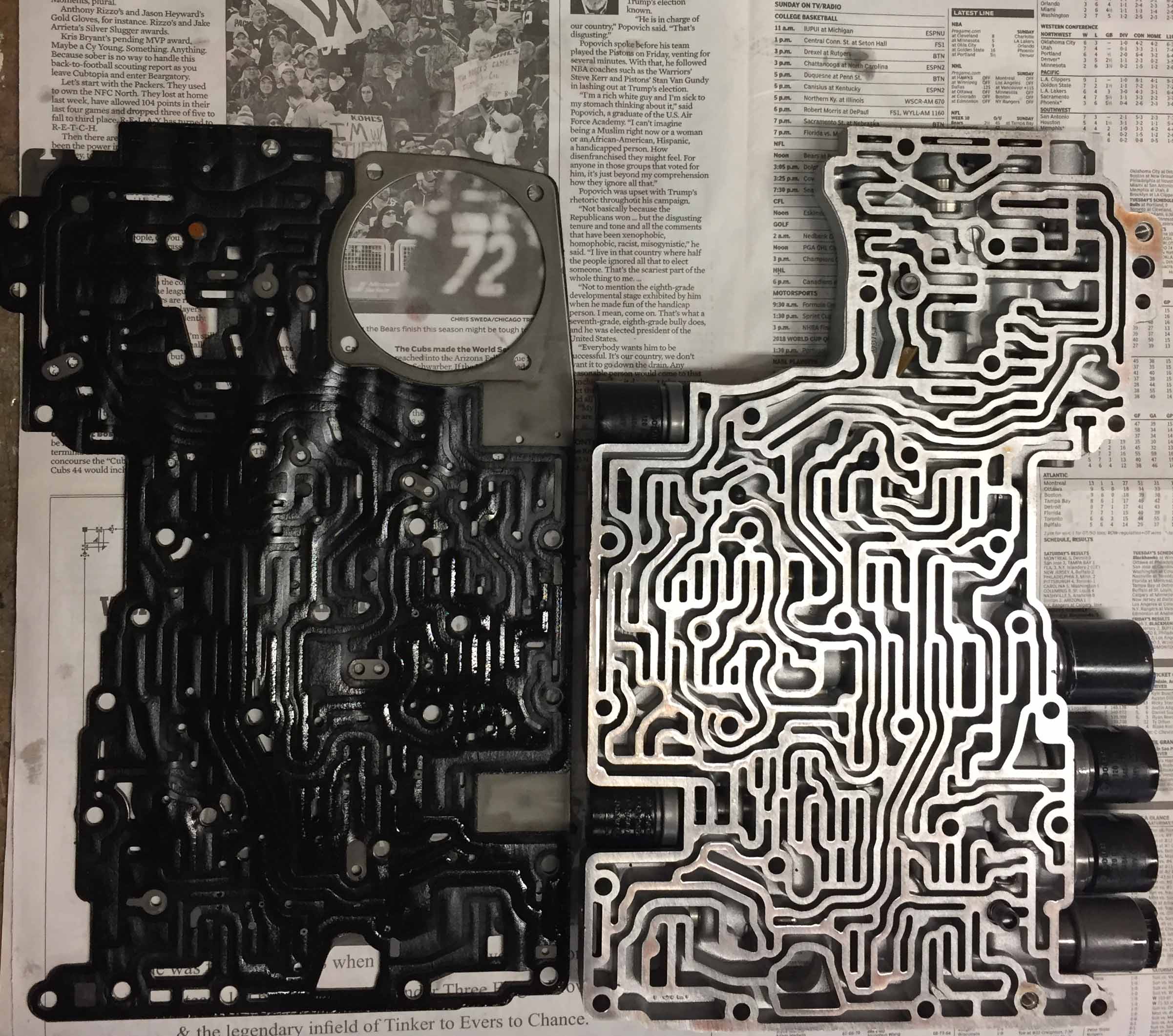

I removed the pan and dropped the valve body out (see PS below) to install the following on this high mileage transmission.

1) EPC Solenoid BW 50155

2) Valve body separator plate with bonded gaskets 1L5Z-7Z490-HA

3) Solenoid bracket XL2Z-7L491-AA

4) Sonnax 4R44E-5R55E-ZIP kit

5) Low/reverse servo piston D-Ring kit seals 23256K

6) Reverse servo cover gasket 23128

7) Transmission Pan Gasket 23141D

I took resistance readings on all the solenoids once I had the VB on the bench:

Solenoid: Reading (Normal)

TCC: 10.1 (8.9-16)

EPC: 4.5 (3.1-5.7) New and old measured the same

Coast Clutch: 25.2 (22-48)

Shift A: 25.4 (22-48)

Shift B: 25.3 (22-48)

Shift C: 25.3 (22-48)

Installation of the components in the Zip Kit was straightforward and the instructions were clear. I did not replace three items as detailed in the Sonnax instructions:

Step 4D: Plug for Bore 109, Coast Clutch/Converter Regulator Valve, as the OEM plug would not come out and I did not want to drill a hole in the valve body as detailed in the Sonnax instructions.

Step 6: Separator Plate Modifications. I left the plate alone, as built by Ford.

Step 7: Smallest inboard cooler bypass spring remove

The only issue I noticed was the condition of the Low/Reverse Servo O-Rings. They appeared to be degraded, and residue on the metal parts was easily cleaned off with acetone. I suggest you test insert this Low/Reverse Servo piston without new O-Rings to confirm the ****ed orientation of it before final assembly.

No problems with the reassembly. Test run revealed it shifted great in all gears, no more delayed reverse. No leaks either.

The Sonnax instructions have torque, bolt length, and other specifications that are useful for any valve body work in these transmissions. See http://d2q1ebiag300ih.cloudfront.ne...ns/2172/4R44E-5R55E-ZIP-IN_B.pdf?v=1487624733

PS

I dropped my oil soaked valve body in a pile of Oil Dry. Not a pretty sight, looked like the last time I made Schnitzel and dredged the egg coated meat through a pile of Panko. Try not to do this.

I was able to wash it by putting the valve body in the transmission pan and pouring mineral spirits over it. It took a few iterations with filtered solvent before I got all of the granules out. Close inspection of the valve body passages with a flashlight revealed a few more bits as well.

I removed the pan and dropped the valve body out (see PS below) to install the following on this high mileage transmission.

1) EPC Solenoid BW 50155

2) Valve body separator plate with bonded gaskets 1L5Z-7Z490-HA

3) Solenoid bracket XL2Z-7L491-AA

4) Sonnax 4R44E-5R55E-ZIP kit

5) Low/reverse servo piston D-Ring kit seals 23256K

6) Reverse servo cover gasket 23128

7) Transmission Pan Gasket 23141D

I took resistance readings on all the solenoids once I had the VB on the bench:

Solenoid: Reading (Normal)

TCC: 10.1 (8.9-16)

EPC: 4.5 (3.1-5.7) New and old measured the same

Coast Clutch: 25.2 (22-48)

Shift A: 25.4 (22-48)

Shift B: 25.3 (22-48)

Shift C: 25.3 (22-48)

Installation of the components in the Zip Kit was straightforward and the instructions were clear. I did not replace three items as detailed in the Sonnax instructions:

Step 4D: Plug for Bore 109, Coast Clutch/Converter Regulator Valve, as the OEM plug would not come out and I did not want to drill a hole in the valve body as detailed in the Sonnax instructions.

Step 6: Separator Plate Modifications. I left the plate alone, as built by Ford.

Step 7: Smallest inboard cooler bypass spring remove

The only issue I noticed was the condition of the Low/Reverse Servo O-Rings. They appeared to be degraded, and residue on the metal parts was easily cleaned off with acetone. I suggest you test insert this Low/Reverse Servo piston without new O-Rings to confirm the ****ed orientation of it before final assembly.

No problems with the reassembly. Test run revealed it shifted great in all gears, no more delayed reverse. No leaks either.

The Sonnax instructions have torque, bolt length, and other specifications that are useful for any valve body work in these transmissions. See http://d2q1ebiag300ih.cloudfront.ne...ns/2172/4R44E-5R55E-ZIP-IN_B.pdf?v=1487624733

PS

I dropped my oil soaked valve body in a pile of Oil Dry. Not a pretty sight, looked like the last time I made Schnitzel and dredged the egg coated meat through a pile of Panko. Try not to do this.

I was able to wash it by putting the valve body in the transmission pan and pouring mineral spirits over it. It took a few iterations with filtered solvent before I got all of the granules out. Close inspection of the valve body passages with a flashlight revealed a few more bits as well.