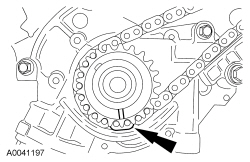

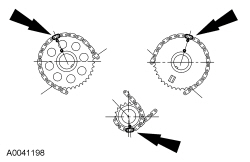

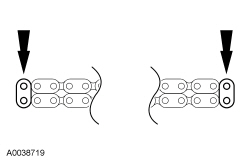

Below are what mine looked like. I marked a link in the left (driver side) camshaft chain, let the chain hang while holding the marked link horizontal, and then marked the corresponding horizontal link at the bottom which would be half way. Then I installed the chain on the crankshaft aft sprocket while aligning the chain mark with the sprocket timing mark.

Then I aligned the other marked chain link with the left (driver side) cam sprocket timing mark.

I did a similar procedure with the right (passenger side) chain, the crankshaft front sprocket and the right camshaft sprocket.

I used a length of insulated wire to keep the tensioner guide and chain in position.