New guy here, fantastic amount of information here.

I have a 03 Explorer with 150k on a 5R55W. It has the 2-3 flare issue. The plan was to replace it with a rebuild but if I can diagnose the fault I might just try a repair.

So far, the pan is off and it's clean aside from some clutch material on the magnet. There's somewhere around 45,000 since the last work was done it. The solenoid pack is off and everything ohms out correctly per the manual. I can see the bands and bottom out the adjuster side so they don't seem to be broken.

At this point, the trans mount is off and the y-pipe has been removed.

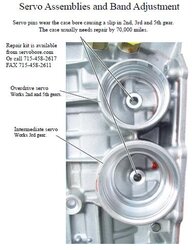

What I want to check next is the intermediate and overdrive servo pistons.

What I'm not sure of is, can the servo pistons be removed without the band struts falling off.

Thanks

I have a 03 Explorer with 150k on a 5R55W. It has the 2-3 flare issue. The plan was to replace it with a rebuild but if I can diagnose the fault I might just try a repair.

So far, the pan is off and it's clean aside from some clutch material on the magnet. There's somewhere around 45,000 since the last work was done it. The solenoid pack is off and everything ohms out correctly per the manual. I can see the bands and bottom out the adjuster side so they don't seem to be broken.

At this point, the trans mount is off and the y-pipe has been removed.

What I want to check next is the intermediate and overdrive servo pistons.

What I'm not sure of is, can the servo pistons be removed without the band struts falling off.

Thanks