Betsy98Sport

Well-Known Member

- Joined

- April 30, 2010

- Messages

- 129

- Reaction score

- 3

- City, State

- San Diego, CA

- Year, Model & Trim Level

- 07 Ford Explorer Eddie B

Hi. I'm about to replace the upper engine gaskets on my 98 explorer 4.0 OHV.The car has about ~160,000 or 120,000 on the block since it's a rebuild I had put in Dec 2004. Since I'm taking the heads off I wanted to take them to a machine shop and have them inspected.

By the way. The main job I'm doing is replacing the head gaskets. After looking through many threads I decided to do this.

Symptoms:

My 4.0 OHV was loosing coolant in the reservoir each day at a slow rate. I keep replacing coolant and it keeps going down. It's been like this for about a year now. I found a leak coming from what I thought was the timing chain cover on the passenger side. I replaced the gaskets on the timing cover and the water pump with Ultra Black RTV and the leak was still there. I found that the leak seems to be coming from the lower intake to head region and also leaking down the passenger side of the block by the exhaust manifold.

There's a noticable stumble/vibrating rumble when the engine is first started cold and when I accelerate or are under load. There is white smoke coming out the tail pipe when first started and goes away after a minute or two of warm-up. The tail pipe also drips a lot when the white smoke comes out. The PCM has spit out P0303 cylinder 3 misfire, and P0171 system too lean (bank 1).

I've done a compression test a few times over the last few months and all the cylinders check out well. However, about 3 months ago when doing a compression test all the cylinders were within 5 psi of 170, but cylinder 3 read 145 the first time then 155 then 160 (I will post these results if needed). The spark plug in clyinder 3 was coated in a red rusty color as well. I ended up replacing the Autolite platinums with Bosch Platinum 4+. Didn't help any.

The last thing is that I have had to frequently flush the cooling system every few months because the coolant ends up turning rusty red with a green tint after a while (possible mixing of oil and coolant). The dipstick always reads higher than the max mark even after oil changes with 5qts and new filter

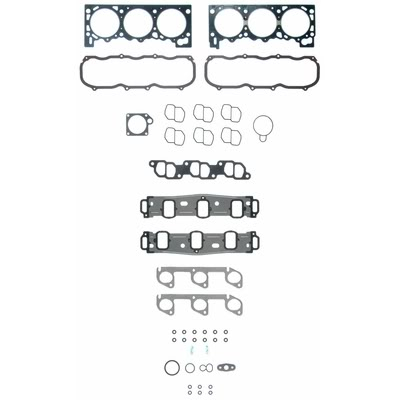

I'm replacing the exhaust, lower intake, fuel rail, upper intake, etc. I purchased the Fel-Pro head gasket set (Part #HST9081PT1) and new head bolts.

Anybody have a list for all the gaskets included? I know most of them except the circular one at the top right and the other two circular ones bottom left

Anybody know any good and fair priced machine shops in San Diego. And also any advice on what to ask to be done for the inspection at the shop would be great. Or also any confirmation on my thoughts or advice Thanks.

I think I'm going to do coolant pressure test on Monday.

By the way. The main job I'm doing is replacing the head gaskets. After looking through many threads I decided to do this.

Symptoms:

My 4.0 OHV was loosing coolant in the reservoir each day at a slow rate. I keep replacing coolant and it keeps going down. It's been like this for about a year now. I found a leak coming from what I thought was the timing chain cover on the passenger side. I replaced the gaskets on the timing cover and the water pump with Ultra Black RTV and the leak was still there. I found that the leak seems to be coming from the lower intake to head region and also leaking down the passenger side of the block by the exhaust manifold.

There's a noticable stumble/vibrating rumble when the engine is first started cold and when I accelerate or are under load. There is white smoke coming out the tail pipe when first started and goes away after a minute or two of warm-up. The tail pipe also drips a lot when the white smoke comes out. The PCM has spit out P0303 cylinder 3 misfire, and P0171 system too lean (bank 1).

I've done a compression test a few times over the last few months and all the cylinders check out well. However, about 3 months ago when doing a compression test all the cylinders were within 5 psi of 170, but cylinder 3 read 145 the first time then 155 then 160 (I will post these results if needed). The spark plug in clyinder 3 was coated in a red rusty color as well. I ended up replacing the Autolite platinums with Bosch Platinum 4+. Didn't help any.

The last thing is that I have had to frequently flush the cooling system every few months because the coolant ends up turning rusty red with a green tint after a while (possible mixing of oil and coolant). The dipstick always reads higher than the max mark even after oil changes with 5qts and new filter

I'm replacing the exhaust, lower intake, fuel rail, upper intake, etc. I purchased the Fel-Pro head gasket set (Part #HST9081PT1) and new head bolts.

Anybody have a list for all the gaskets included? I know most of them except the circular one at the top right and the other two circular ones bottom left

Anybody know any good and fair priced machine shops in San Diego. And also any advice on what to ask to be done for the inspection at the shop would be great. Or also any confirmation on my thoughts or advice Thanks.

I think I'm going to do coolant pressure test on Monday.