I haven't posted much here since I sold my 1993 Mazda Navajo around 2010 or 2011. It was 10 years in the making and finally to a solid, reliable state. I had some other priorities and decided to sell it and get something more versatile. I will include some pictures below of its developing states and final state when I sold it below. In the end, it had 37" MTRs, Arb front, detroit rear, 4.56 gears, D and D doubler and I built all the armor and the Dana 44 front Solid Axle Swap.

James duff 3.5" VR coil lift, 235" defender tires and a home made heavy ugly bumper (around 2000 when I bought it) :

2001 with 33x10.50s and James duff 4.5" lift with extended radius arms, manual hubs and new auto tranny:

Here it is just after the SAS with 34s and a swapped in manual tcase and tranny:

Winching out of Mikeys hot tub circa 2002 or so

Stuck on a tree just after 37s

37s, winch bumper rebuild etc

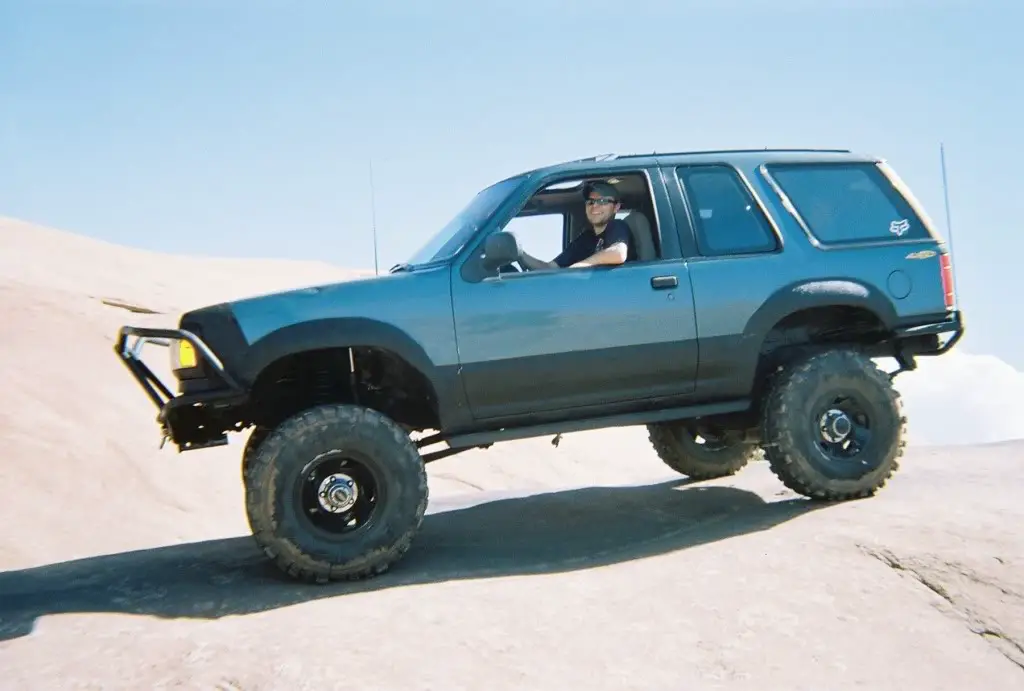

Final State Explorerforum moab trip 2010

Last Poser Shots

I hear it still gets around Colorado and Utah and I have had buddies call me with airings from time to time.

I have had a few rangers and one explorer since I sold my explorer.

Here are some pics of those:

Beat up 1994 Ranger 2.4l ($250)

Traded 1993 Ranger 4.0l and an abused auto tranny

1991 Manual Tcase and Tranny Explorer Sport

We have also had a ton of cool Jeeps. Here are a couple of pics, along with our current Jeep which we are hanging on to:

2005 unlimited Rubicon Sahara 5.7 L Hemi

2005 unlimited Rubicon 35s and 4" lift

Our Current 2005 Unlimited Rubicon 4" Lift 315 Kevlars

It does great grocery getter, family truckster, and occasional wekend wheeler, but I need a truck and I miss my exploder, so I decided to build a Ranger. However, I want to build it a little different this time.

I have always wanted to build a 1989-1992 ranger, so I spent a considerable amount of time looking for a low mile one with the right engine, tranny and tcase in good shape. 4.0l, m5od and 1354M stock. My explorer ended up with this combo, but started out as an auto tranny and tcase. This made for a ton of modifications and headaches with my explorer. Rangers can be had in many other undesirable configurations because they were available with 3 different v6s in 1989-92 and a 4cylinder. It proved to be a difficult task. Finally in the fall of 2012 I picked this one up. A 1991 4.0l manual tranny and transfer case 4x4 extended cab "mountain States Edition. It had 130k on it and ran great. The paint was toast, it had a rusty bed and (my biggest complaint) it had no factory air.

I drove it for a year until I was ready to have it painted. I fixed a bunch on it- thermostat, muffler, wheel bearings, brakes, had a new headliner installed, etc. When I got a quote for the paint (one solid color and fix the dings) it was 2k. So then I started thinking I better look for a different ranger to build! I settled on this one. It too is a 1991, it has air (huge plus after not having it in my other truck all summer), manual case and tranny and everything else and a 4.0. The body is really straight no rust and the interior is super nice. The odo read 83k and I believed it.

Since then I tracked down the original and only owner to find it has 183 k on it and they were all hwy miles. The only complaints I have is I wish it had the other mirrors and pop out extended cab windows. I can deal with those, though. This truck has been taken care of.

First order of business was a tune up, brakes and leaky valve cover gaskets.

The build plan is pretty simple: build it similar to how my explorer ended up, with out all the half builds in between. It took me a lot of work and money to get my explorer to preform well off-road and on the street and be reliable. On this one I want to skip all the poor performing, cheapskate half steps I took with the explorer.

My goal is to end up with a reliable, daily drive able, off-road capable ranger that will make a great driver, great work truck and great expo vehicle. I like the idea of a truck over a explorer sport because I need to haul dirt bikes and Sheetrock and plywood and all kinds of stuff all the time so I always needed a pickup when I had the explorer even though I wanted to drive the explorer all the time. Hopefully this will do both functions well.

So far, I have installed:

A blue tooth pioneer stereo (replacing the stock tape deck)

A optima yellow top

A Black grill and headlight bezels along with new headlights:

The only body work it needs is the topper it had on it was put on with a loose and poorly placed clamp that rubbed a hole in the bed cap. I will weld it up and hopefully add a LineX bedliner over the top

I purchased a Dana 44 out of a 76 f150 with no guts or outers for a $50 bill. I still have my spare warn premium hubs off my ex, and I plan to build this one stout before I put it in and leave it full width but move the c bushings in about 2" per side. I will likely then run stock style f150 wheels with stock backspacing and 35s or 37s as skinny as I can find. It will get a full rebuild and at least 4.88s, maybe 5.13s. I am not decided on radius arms yet. I suppose extended ones are on the bill instead of the stock wristed ones I had before, but I haven't sorted that out yet. The wrist traveled fine but it clunked and made a racket and it was also a pain to get out and pull the pin when it was time to wheel. Extended arms won't perform quite as well on the street as the stock length ones did with the pin in, but longer arms should stream line things.

For the rear I will rebuild a full width late model 31 spline 8.8 put of a bronco or f150 and install explorer disk brakes. I will likely need to have the axle flanges turned down and drill the rotors for the new bolt pattern.

I will extend the wheel base around 3" by moving the front axle forward and leave the rear axle centered in the wheel well. I plan to leave the bed size stock as I need the truck to haul stuff all the time. I will build bumpers and sliders before I beat it up this time.

Stay Tuned, I am picking up the front axle tomorrow.

James duff 3.5" VR coil lift, 235" defender tires and a home made heavy ugly bumper (around 2000 when I bought it) :

2001 with 33x10.50s and James duff 4.5" lift with extended radius arms, manual hubs and new auto tranny:

Here it is just after the SAS with 34s and a swapped in manual tcase and tranny:

Winching out of Mikeys hot tub circa 2002 or so

Stuck on a tree just after 37s

37s, winch bumper rebuild etc

Final State Explorerforum moab trip 2010

Last Poser Shots

I hear it still gets around Colorado and Utah and I have had buddies call me with airings from time to time.

I have had a few rangers and one explorer since I sold my explorer.

Here are some pics of those:

Beat up 1994 Ranger 2.4l ($250)

Traded 1993 Ranger 4.0l and an abused auto tranny

1991 Manual Tcase and Tranny Explorer Sport

We have also had a ton of cool Jeeps. Here are a couple of pics, along with our current Jeep which we are hanging on to:

2005 unlimited Rubicon Sahara 5.7 L Hemi

2005 unlimited Rubicon 35s and 4" lift

Our Current 2005 Unlimited Rubicon 4" Lift 315 Kevlars

It does great grocery getter, family truckster, and occasional wekend wheeler, but I need a truck and I miss my exploder, so I decided to build a Ranger. However, I want to build it a little different this time.

I have always wanted to build a 1989-1992 ranger, so I spent a considerable amount of time looking for a low mile one with the right engine, tranny and tcase in good shape. 4.0l, m5od and 1354M stock. My explorer ended up with this combo, but started out as an auto tranny and tcase. This made for a ton of modifications and headaches with my explorer. Rangers can be had in many other undesirable configurations because they were available with 3 different v6s in 1989-92 and a 4cylinder. It proved to be a difficult task. Finally in the fall of 2012 I picked this one up. A 1991 4.0l manual tranny and transfer case 4x4 extended cab "mountain States Edition. It had 130k on it and ran great. The paint was toast, it had a rusty bed and (my biggest complaint) it had no factory air.

I drove it for a year until I was ready to have it painted. I fixed a bunch on it- thermostat, muffler, wheel bearings, brakes, had a new headliner installed, etc. When I got a quote for the paint (one solid color and fix the dings) it was 2k. So then I started thinking I better look for a different ranger to build! I settled on this one. It too is a 1991, it has air (huge plus after not having it in my other truck all summer), manual case and tranny and everything else and a 4.0. The body is really straight no rust and the interior is super nice. The odo read 83k and I believed it.

Since then I tracked down the original and only owner to find it has 183 k on it and they were all hwy miles. The only complaints I have is I wish it had the other mirrors and pop out extended cab windows. I can deal with those, though. This truck has been taken care of.

First order of business was a tune up, brakes and leaky valve cover gaskets.

The build plan is pretty simple: build it similar to how my explorer ended up, with out all the half builds in between. It took me a lot of work and money to get my explorer to preform well off-road and on the street and be reliable. On this one I want to skip all the poor performing, cheapskate half steps I took with the explorer.

My goal is to end up with a reliable, daily drive able, off-road capable ranger that will make a great driver, great work truck and great expo vehicle. I like the idea of a truck over a explorer sport because I need to haul dirt bikes and Sheetrock and plywood and all kinds of stuff all the time so I always needed a pickup when I had the explorer even though I wanted to drive the explorer all the time. Hopefully this will do both functions well.

So far, I have installed:

A blue tooth pioneer stereo (replacing the stock tape deck)

A optima yellow top

A Black grill and headlight bezels along with new headlights:

The only body work it needs is the topper it had on it was put on with a loose and poorly placed clamp that rubbed a hole in the bed cap. I will weld it up and hopefully add a LineX bedliner over the top

I purchased a Dana 44 out of a 76 f150 with no guts or outers for a $50 bill. I still have my spare warn premium hubs off my ex, and I plan to build this one stout before I put it in and leave it full width but move the c bushings in about 2" per side. I will likely then run stock style f150 wheels with stock backspacing and 35s or 37s as skinny as I can find. It will get a full rebuild and at least 4.88s, maybe 5.13s. I am not decided on radius arms yet. I suppose extended ones are on the bill instead of the stock wristed ones I had before, but I haven't sorted that out yet. The wrist traveled fine but it clunked and made a racket and it was also a pain to get out and pull the pin when it was time to wheel. Extended arms won't perform quite as well on the street as the stock length ones did with the pin in, but longer arms should stream line things.

For the rear I will rebuild a full width late model 31 spline 8.8 put of a bronco or f150 and install explorer disk brakes. I will likely need to have the axle flanges turned down and drill the rotors for the new bolt pattern.

I will extend the wheel base around 3" by moving the front axle forward and leave the rear axle centered in the wheel well. I plan to leave the bed size stock as I need the truck to haul stuff all the time. I will build bumpers and sliders before I beat it up this time.

Stay Tuned, I am picking up the front axle tomorrow.