arco777

Explorer Addict

- Joined

- April 6, 2008

- Messages

- 2,404

- Reaction score

- 59

- Year, Model & Trim Level

- 1994 Explorer 2dr 4x4

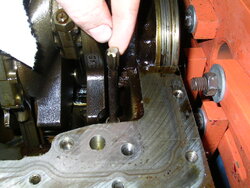

Timing cover removal. Note that my engine is still upside down...

1. Quite a few different types of fasteners so pay attention to what you remove and where it came from.

2. Top left and right (normally bottom right and left) have 13mm heads. One is just a standard bolt with an odd head that looks like it was meant to be a stud. The other is a stud and has a nut on it holding the bracket for one of the heater hoses.

3. This bracket thing is soft metal so loosen each nut just a little at first. In my case, one side the nut came off and the other side the whole stud came out, so it wanted to twist the bracket.

4. More studs for a 13mm deep socket.

5. I'm removing the crank position sensor. 10mm socket on the two bolts.

6. These short bolts are all identical length. 10mm socket.

7. Cover comes off without much fight.

1. Quite a few different types of fasteners so pay attention to what you remove and where it came from.

2. Top left and right (normally bottom right and left) have 13mm heads. One is just a standard bolt with an odd head that looks like it was meant to be a stud. The other is a stud and has a nut on it holding the bracket for one of the heater hoses.

3. This bracket thing is soft metal so loosen each nut just a little at first. In my case, one side the nut came off and the other side the whole stud came out, so it wanted to twist the bracket.

4. More studs for a 13mm deep socket.

5. I'm removing the crank position sensor. 10mm socket on the two bolts.

6. These short bolts are all identical length. 10mm socket.

7. Cover comes off without much fight.