2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,597

- Reaction score

- 334

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

The SOHC V6 is an interference engine. If the valve timing relative to the crankshaft is excessively in error, pistons and valves may collide resulting in engine damage. The photo below by cjmedina shows the results of a slipped rear timing chain. The timing slipped 50 camshaft degrees and the exhaust valves struck the pistons.

Accurate and correct camshaft timing is required for safe engine operation and to achieve designed engine performance.

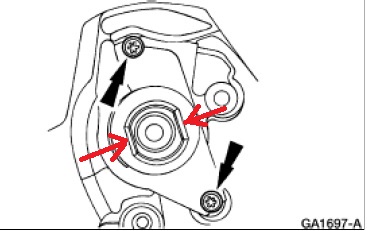

There are no keys on the SOHC V6 jackshaft rear sprocket, the left camshaft sprocket nor the right camshaft sprocket. The sprockets are held in position entirely by the force exerted by their retaining bolts. There is a flat spot on the internal opposite sides of the jackshaft front flange (red arrows in photo below).

There are matching flats on the external shaft of the primary sprocket assembly but there is considerable rotational play between the primary sprocket shaft and the jackshaft flange. If the jackshaft front sprocket is loosened both camshafts should be retimed. If one of the camshaft sprockets is loosened then that camshaft must be retimed.

It is not possible to properly replace the front upper left timing chain or guide assembly without removing the jackshaft front sprocket. It may be possible to remove the left guide assembly pivot bolt without removing the jackshaft front sprocket but the bolt cannot be correctly torqued since access by a torque wrench is blocked by the jackshaft sprocket.

It is not possible to replace the rear upper right timing chain without removing the jackshaft rear sprocket. Since the cover for the jackshaft rear sprocket is behind the flexplate/flywheel, replacement of the rear cassette requires pulling either the engine or the transmission.

It is possible to replace the primary chain tensioner and guide without loosening the jackshaft front sprocket so no retiming is required. Replacing the primary chain requires removal of the jackshaft front sprocket and retiming of both camshafts.

Removing an engine head requires disconnecting the camshaft sprocket and subsequent retiming of the camshaft.

If a camshaft is removed for valve train work the camshaft must be retimed. Some valve train work is possible without camshaft removal but special tools may be required.

Requirements for accurate timing

The following list identifies the requirements to achieve accurate camshaft timing after all timing chain components and camshafts are installed on the engine.

1. The crankshaft must be locked in position (rotational motion in either direction prevented) with the #1 piston (right front of engine) at top dead center (TDC) on the compression stroke (intake and exhaust valves closed).

2. The jackshaft front and rear sprocket bolts must be tightened to the specified torque.

3.a. The right camshaft must be locked in position with the camshaft lobes for cylinder #1 not depressing the valves and the timing notch at the front of the camshaft below the camshaft centeline and parallel to the head surface that mates to the valve cover.

3.b. The traction side of the right timing chain must be taught (in tension).

3.c. The right camshaft sprocket bolt is torqued (tightens counter-clockwise) to 63 ft-lb (85 Nm)

4.a. The left camshaft must be locked in position with the camshaft position sensor protrusion above the camshaft centerline and the timing notch at the rear of the camshaft below the camshaft centeline and parallel to the head surface that mates to the valve cover.

4.b. The traction side of the left timing chain must be taught (in tension).

4.c. The left camshaft sprocket bolt is torqued (tightens clockwise) to 63 ft-lb (85 Nm)

Comments:

Some members have implemented creative methods to time their camshafts without purchasing the special timing kit OTC-6488. Unless a method to keep the chain taught when tightening the camshaft sprocket bolt is implemented the timing will not be accurate. The spring pressure provided by the normal spring/hydraulic tensioner is inadequate to tension the chain for timing. A bolt, washer and nut may be a suitable alternative for Timing Chain Tensioner Tool 303-571 (T97T-6K254-A) that is included with the timing kit.

Notes:

The camshaft sprocket bolts are not torque to yield and may be reused.

The jackshaft front and rear sprocket bolts are torque to yield and may not be reused.

The crankshaft damper bolt is a torque to yield and may not be reused.

The following tasks require separation of the engine and transmission. Accessibility to accomplish the task is significantly improved by pulling the engine rather than the transmission.

1. Rear timing chain replacement (requires flywheel/flexplate removal)

2. Rear timing chain guide assembly replacement

3. Jackshaft removal (requires flywheel/flexplate removal)

4. Jackshaft rear sprocket replacement (requires flywheel/flexplate removal)

Related Ford part numbers:

Jackshaft/primary timing chain kit 2U3Z6D256CA includes:

Crankshaft bolt harmonic balancer E7RY6A340B

Tensioner-engine jackshaft chain YL2Z6L266AA

Gasket-cylinder/timing front cover F77Z6020AB

Sprocket/gear-engine jackshaft/intermediate 2U3Z6M264AA

Guide-engine jackshaft chain 2L2Z6K297AA

Bolt-jackshaft sprocket bolt F77Z6M264BA superseded by 2L2Z6279AA (included when 2U3Z6M264AA is purchased)

Sprocket/gear-crankshaft two wheel drive 2L2Z6306BA

Chain-engine jackshaft F77Z6268AB

Bolt-camshaft sprocket right hand

Bolt-camshaft sprocket left hand F77Z6279BA

Left/front timing chain cassette assembly 7U3Z6A257A includes:

Timing chain

Guide assembly YL2Z6M273AA superseded by 7U3Z6A257A

Bolt-guide assembly upper mount

Sprocket/gear-camshaft

Sprocket/gear-jackshaft front

Right/rear timing chain cassette assembly 4L2Z6M290AA includes:

Timing chain

Guide assembly

Sprocket/gear-camshaft

Sprocket/gear-jackshaft rear

00M12 intake manifold kit YL2Z9E473AA includes:

Lower intake manifold gasket set of six YL2Z9461AA

Upper intake manifold gasket set of two YL2Z9E436AA

Left timing chain tensioner 7U3Z6K254B

Tensioner metal O ring XU2Z6M252AA

Oil restrictor

Galley plug

Right timing chain tensioner 7U3Z6K254A supersedes XU3Z6K254BA

Right timing chain guide assembly upper postioning bolt F77Z6U000BA

Jackshaft rear sprocket retaining bolt W703167S430

Cover assy/rear of block jackshaft opening plug F77Z6026AB

Left cassette assembly lower mounting bolt W500100S300

Jackshaft chain guide mounting bolt W500100S300

Sprocket/gear-crankshaft inner four wheel drive F77Z6306BE

Sprocket/gear - crankshaft outer four wheel drive 2L2Z6306AA

Balance shaft chain guide F77Z6K297BC

Balance shaft chain tensioner 1L2Z6L266AA

Balance shaft chain F77Z6268BC

Balance shaft assembly 1L2Z6A311AA

Seal-front timing cover E6TZ6700A was superseded by 5H2Z6700AA

Gasket set-valve cover F77Z6584AE

Gasket-lower oil pan 4L2Z6710AA year 2000+ F77Z6710BA year 1997-1999

Gasket-upper oil pan/reinforcement section F77Z6710AA

Left camshaft F7TZ6250AEE was superseded by 7L2Z6250D

Right camshaft F77Z6250AE

Exhaust manifold outlet bolts (M12-1.75X54.5 H) N811747S2

Accurate and correct camshaft timing is required for safe engine operation and to achieve designed engine performance.

There are no keys on the SOHC V6 jackshaft rear sprocket, the left camshaft sprocket nor the right camshaft sprocket. The sprockets are held in position entirely by the force exerted by their retaining bolts. There is a flat spot on the internal opposite sides of the jackshaft front flange (red arrows in photo below).

There are matching flats on the external shaft of the primary sprocket assembly but there is considerable rotational play between the primary sprocket shaft and the jackshaft flange. If the jackshaft front sprocket is loosened both camshafts should be retimed. If one of the camshaft sprockets is loosened then that camshaft must be retimed.

It is not possible to properly replace the front upper left timing chain or guide assembly without removing the jackshaft front sprocket. It may be possible to remove the left guide assembly pivot bolt without removing the jackshaft front sprocket but the bolt cannot be correctly torqued since access by a torque wrench is blocked by the jackshaft sprocket.

It is not possible to replace the rear upper right timing chain without removing the jackshaft rear sprocket. Since the cover for the jackshaft rear sprocket is behind the flexplate/flywheel, replacement of the rear cassette requires pulling either the engine or the transmission.

It is possible to replace the primary chain tensioner and guide without loosening the jackshaft front sprocket so no retiming is required. Replacing the primary chain requires removal of the jackshaft front sprocket and retiming of both camshafts.

Removing an engine head requires disconnecting the camshaft sprocket and subsequent retiming of the camshaft.

If a camshaft is removed for valve train work the camshaft must be retimed. Some valve train work is possible without camshaft removal but special tools may be required.

Requirements for accurate timing

The following list identifies the requirements to achieve accurate camshaft timing after all timing chain components and camshafts are installed on the engine.

1. The crankshaft must be locked in position (rotational motion in either direction prevented) with the #1 piston (right front of engine) at top dead center (TDC) on the compression stroke (intake and exhaust valves closed).

2. The jackshaft front and rear sprocket bolts must be tightened to the specified torque.

3.a. The right camshaft must be locked in position with the camshaft lobes for cylinder #1 not depressing the valves and the timing notch at the front of the camshaft below the camshaft centeline and parallel to the head surface that mates to the valve cover.

3.b. The traction side of the right timing chain must be taught (in tension).

3.c. The right camshaft sprocket bolt is torqued (tightens counter-clockwise) to 63 ft-lb (85 Nm)

4.a. The left camshaft must be locked in position with the camshaft position sensor protrusion above the camshaft centerline and the timing notch at the rear of the camshaft below the camshaft centeline and parallel to the head surface that mates to the valve cover.

4.b. The traction side of the left timing chain must be taught (in tension).

4.c. The left camshaft sprocket bolt is torqued (tightens clockwise) to 63 ft-lb (85 Nm)

Comments:

Some members have implemented creative methods to time their camshafts without purchasing the special timing kit OTC-6488. Unless a method to keep the chain taught when tightening the camshaft sprocket bolt is implemented the timing will not be accurate. The spring pressure provided by the normal spring/hydraulic tensioner is inadequate to tension the chain for timing. A bolt, washer and nut may be a suitable alternative for Timing Chain Tensioner Tool 303-571 (T97T-6K254-A) that is included with the timing kit.

Notes:

The camshaft sprocket bolts are not torque to yield and may be reused.

The jackshaft front and rear sprocket bolts are torque to yield and may not be reused.

The crankshaft damper bolt is a torque to yield and may not be reused.

The following tasks require separation of the engine and transmission. Accessibility to accomplish the task is significantly improved by pulling the engine rather than the transmission.

1. Rear timing chain replacement (requires flywheel/flexplate removal)

2. Rear timing chain guide assembly replacement

3. Jackshaft removal (requires flywheel/flexplate removal)

4. Jackshaft rear sprocket replacement (requires flywheel/flexplate removal)

Related Ford part numbers:

Jackshaft/primary timing chain kit 2U3Z6D256CA includes:

Crankshaft bolt harmonic balancer E7RY6A340B

Tensioner-engine jackshaft chain YL2Z6L266AA

Gasket-cylinder/timing front cover F77Z6020AB

Sprocket/gear-engine jackshaft/intermediate 2U3Z6M264AA

Guide-engine jackshaft chain 2L2Z6K297AA

Bolt-jackshaft sprocket bolt F77Z6M264BA superseded by 2L2Z6279AA (included when 2U3Z6M264AA is purchased)

Sprocket/gear-crankshaft two wheel drive 2L2Z6306BA

Chain-engine jackshaft F77Z6268AB

Bolt-camshaft sprocket right hand

Bolt-camshaft sprocket left hand F77Z6279BA

Left/front timing chain cassette assembly 7U3Z6A257A includes:

Timing chain

Guide assembly YL2Z6M273AA superseded by 7U3Z6A257A

Bolt-guide assembly upper mount

Sprocket/gear-camshaft

Sprocket/gear-jackshaft front

Right/rear timing chain cassette assembly 4L2Z6M290AA includes:

Timing chain

Guide assembly

Sprocket/gear-camshaft

Sprocket/gear-jackshaft rear

00M12 intake manifold kit YL2Z9E473AA includes:

Lower intake manifold gasket set of six YL2Z9461AA

Upper intake manifold gasket set of two YL2Z9E436AA

Left timing chain tensioner 7U3Z6K254B

Tensioner metal O ring XU2Z6M252AA

Oil restrictor

Galley plug

Right timing chain tensioner 7U3Z6K254A supersedes XU3Z6K254BA

Right timing chain guide assembly upper postioning bolt F77Z6U000BA

Jackshaft rear sprocket retaining bolt W703167S430

Cover assy/rear of block jackshaft opening plug F77Z6026AB

Left cassette assembly lower mounting bolt W500100S300

Jackshaft chain guide mounting bolt W500100S300

Sprocket/gear-crankshaft inner four wheel drive F77Z6306BE

Sprocket/gear - crankshaft outer four wheel drive 2L2Z6306AA

Balance shaft chain guide F77Z6K297BC

Balance shaft chain tensioner 1L2Z6L266AA

Balance shaft chain F77Z6268BC

Balance shaft assembly 1L2Z6A311AA

Seal-front timing cover E6TZ6700A was superseded by 5H2Z6700AA

Gasket set-valve cover F77Z6584AE

Gasket-lower oil pan 4L2Z6710AA year 2000+ F77Z6710BA year 1997-1999

Gasket-upper oil pan/reinforcement section F77Z6710AA

Left camshaft F7TZ6250AEE was superseded by 7L2Z6250D

Right camshaft F77Z6250AE

Exhaust manifold outlet bolts (M12-1.75X54.5 H) N811747S2

hello everybody what if i had a 4.0 ohc v-6 with ROCKER ARM SET-UP FROM FACTORY VIN X IT SET-UP LIKE OHV BUT BUT OHC WITH ROCKER ARM SET-UP

hello everybody what if i had a 4.0 ohc v-6 with ROCKER ARM SET-UP FROM FACTORY VIN X IT SET-UP LIKE OHV BUT BUT OHC WITH ROCKER ARM SET-UP