- Joined

- November 11, 2005

- Messages

- 57,113

- Reaction score

- 1,416

- City, State

- Brooklyn, NY

- Year, Model & Trim Level

- 88 89 93 95 96 Aerostars

Routine maintenance falls into many categories such as replacing spark plugs, cables, air filter, breather element (if equipped), cabin filter (if equipped), fuel filter, cleaning battery terminals, fluids, etc. There are other things which are just as important, but don't usually get cleaned such as the mass air flow sensor, idle air control solenoid, PCV, and the air charge temperature sensor. Those parts either get cleaned or replaced once there is a problem, but not as preventative maintenance.

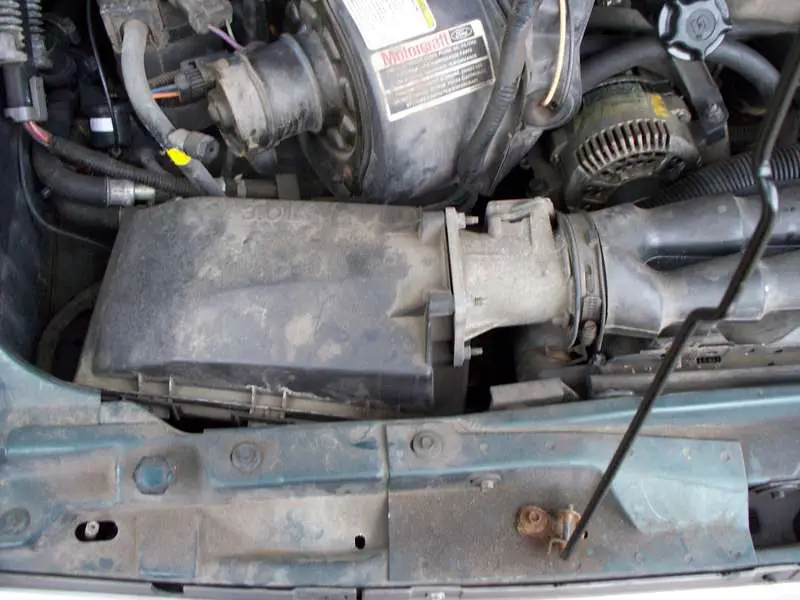

This is the mass air flow sensor on a 1995 Aerostar with a 3.0L:

This is the recommended chemical spray for cleaning it:

Some chemicals leave a residue behind that sticks to the element, and causes it to attract dust & dirt. This spray leaves no residue, and evaporates quickly. This is the inside with a block off plate held in place with two T-20 security Torx screws:

It's not necessary to remove anything other than this plate to get to the two internal elements. Here is a view with the plate removed:

The two elements are shown in the small cut out of this picture as well as the opposite side of the MAF:

This is a diagram of how the MAF works:

The next thing on the list is the throttle body. The plate should be cleaned on both sides with fuel injection safe intake cleaner:

This will clean, and lubricate the moving parts of the throttle body. Don't use carburetor cleaner on a fuel injected engine! Oxygen sensors, and other parts might get ruined if you use harsh cleaning chemicals that are not approved for fuel injected vehicles. The next part on the list is the idle air control solenoid valve. Spray intake cleaner into these two channels on the bottom of this part:

The next part is for the 3.0L engines. It's the air charge temperature sensor which is on the top of the intake manifold:

This is what the sensing element looks like:

The small stem in the open part of the housing detects the temperature of the air flowing into the engine. This is a graph of the temperature curve in proportion to voltage:

This is the pin out for the sensor:

The last thing on this list is the positive crankcase ventillation (PCV) valve:

This part usually gets replaced, but a few blasts of cleaning spray does a good job getting all of the oil deposits out.

This is the mass air flow sensor on a 1995 Aerostar with a 3.0L:

This is the recommended chemical spray for cleaning it:

Some chemicals leave a residue behind that sticks to the element, and causes it to attract dust & dirt. This spray leaves no residue, and evaporates quickly. This is the inside with a block off plate held in place with two T-20 security Torx screws:

It's not necessary to remove anything other than this plate to get to the two internal elements. Here is a view with the plate removed:

The two elements are shown in the small cut out of this picture as well as the opposite side of the MAF:

This is a diagram of how the MAF works:

The next thing on the list is the throttle body. The plate should be cleaned on both sides with fuel injection safe intake cleaner:

This will clean, and lubricate the moving parts of the throttle body. Don't use carburetor cleaner on a fuel injected engine! Oxygen sensors, and other parts might get ruined if you use harsh cleaning chemicals that are not approved for fuel injected vehicles. The next part on the list is the idle air control solenoid valve. Spray intake cleaner into these two channels on the bottom of this part:

The next part is for the 3.0L engines. It's the air charge temperature sensor which is on the top of the intake manifold:

This is what the sensing element looks like:

The small stem in the open part of the housing detects the temperature of the air flowing into the engine. This is a graph of the temperature curve in proportion to voltage:

This is the pin out for the sensor:

The last thing on this list is the positive crankcase ventillation (PCV) valve:

This part usually gets replaced, but a few blasts of cleaning spray does a good job getting all of the oil deposits out.