BigPerm

Member

- Joined

- December 3, 2011

- Messages

- 25

- Reaction score

- 1

- City, State

- Texas

- Year, Model & Trim Level

- 1995 Explorer Sport

I wanted to take a little time here to create a thread on how I repaired both of power window motors. I own a 1995 Explorer Sport and I have been pretty much rebuilding it since I bought it. Over the past few months both of my windows began to fail on me, first they went intermittent and then just failed completely. I have attached a short clip here to let you hear what they sounded like before the repair. As you can hear the motor is fully functional it just sounded like the gears were stripped out inside. Once the motor was out it took me all of about 20 minutes to fix the motor.

I will do my best to explain my way through the pics and how everything was done, but it was actually very simple. Im sure someone out there can make it even easier than this but it sure worked for me. I fixed my first motor almost a month ago and it is used daily and it hasnt even come close to failing on me since I fixed it.

Here are the tools that I used for the repair job; a power drill with small drill bits, 1/16 to 1/8" at the largest. A flat head screw driver, a T-15 Torx driver or bit, a piece of sandpaper, some needlenose pliers, and some type of fast bond epoxy glue (I used Locktite brand), a good vice doesn't hurt to have, and of course there is the Driver side window motor fresh out of my door.

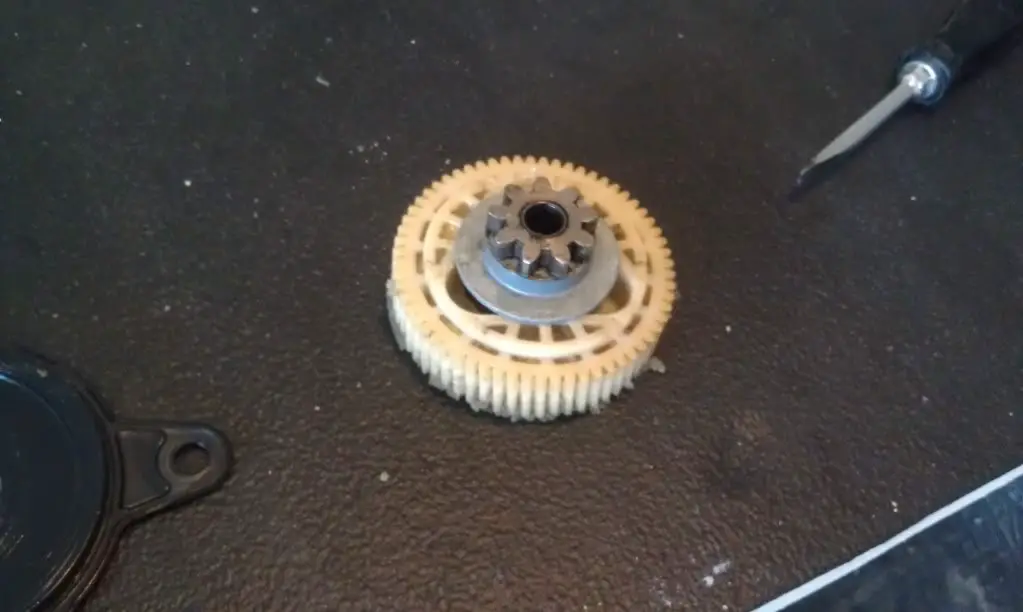

First step was to use the Torx bit to take the cover plate off the motor. As you can see the guts are very simple, all you have is a plastic gear that is driven by the actual motor that is supposed to turn the inner metal gear which actuates the window assembly inside the door.

The gears are held onto the center post by this little ring which I just used some needlenose to remove. BUT BE CAREFUL, THIS LITTLE RETAINER RING IS MIGHTY SPRINGY!!!

Okay once you have removed the retainer ring simply lift the two gears out together as a single unit.

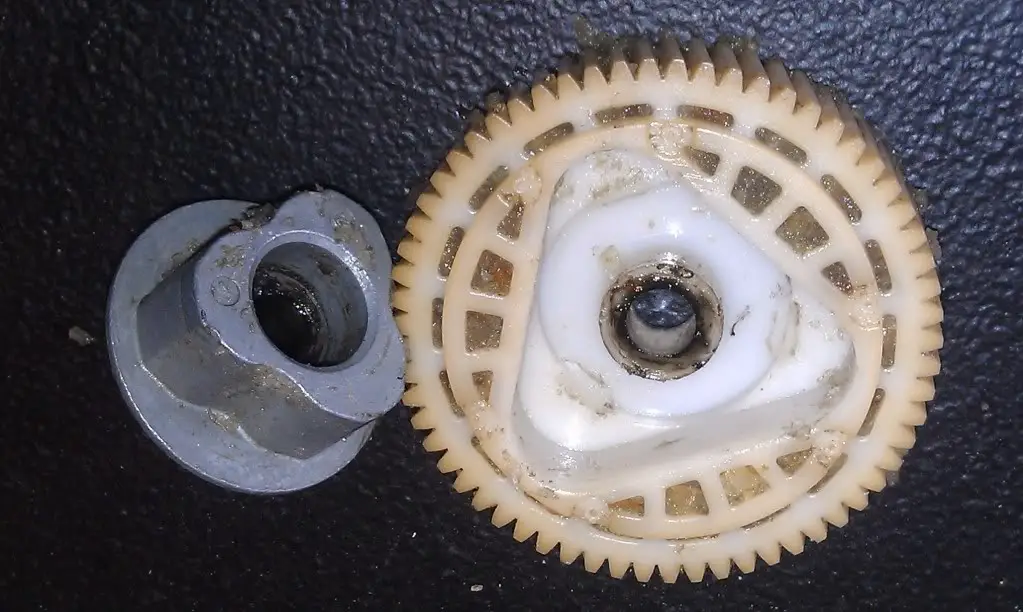

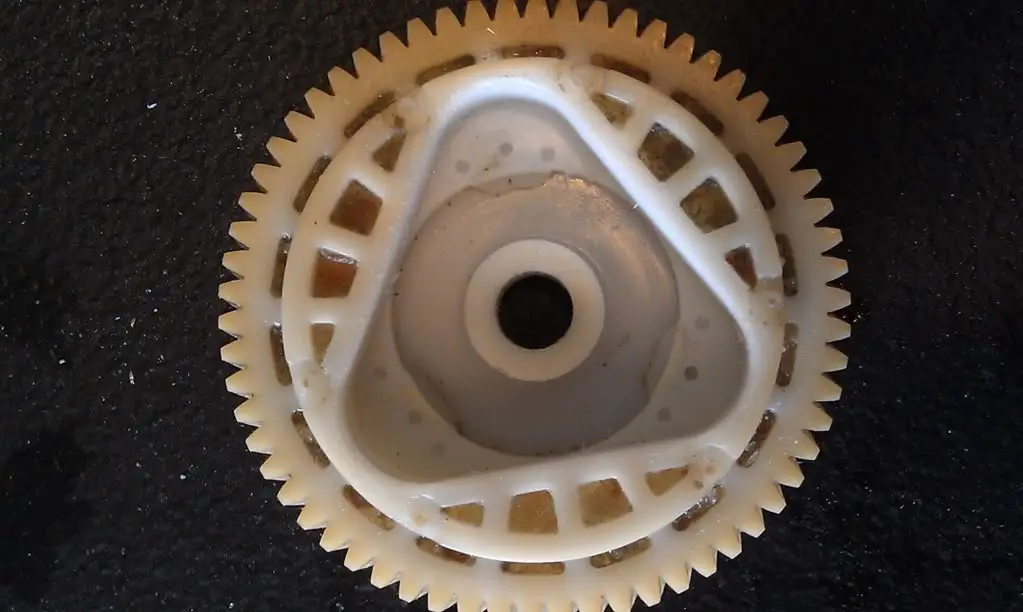

The two gears just come apart. Here you can see how the bottom of the metal gear has an almost "three leaf clover" shape to it.

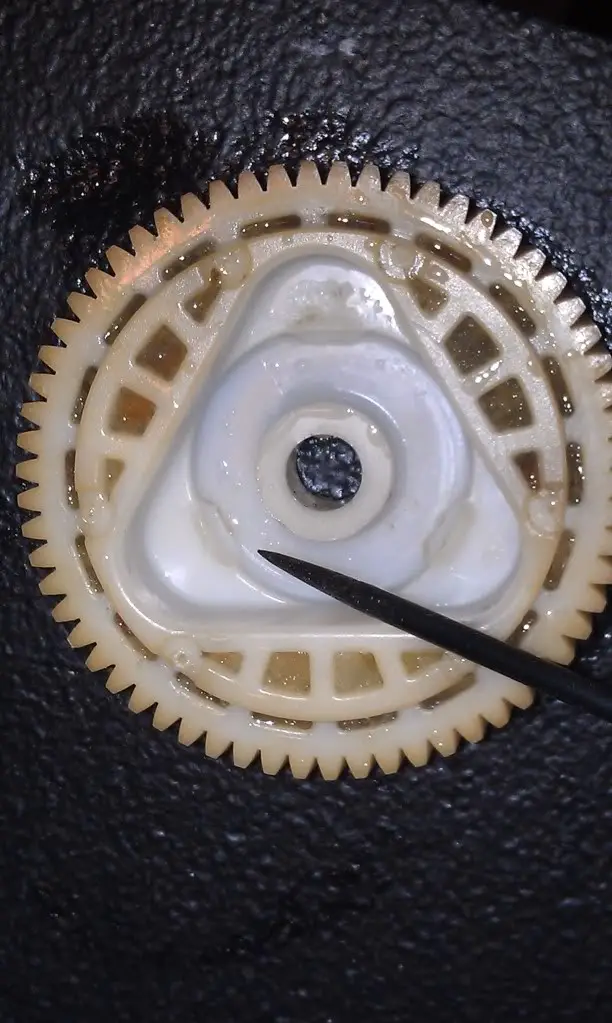

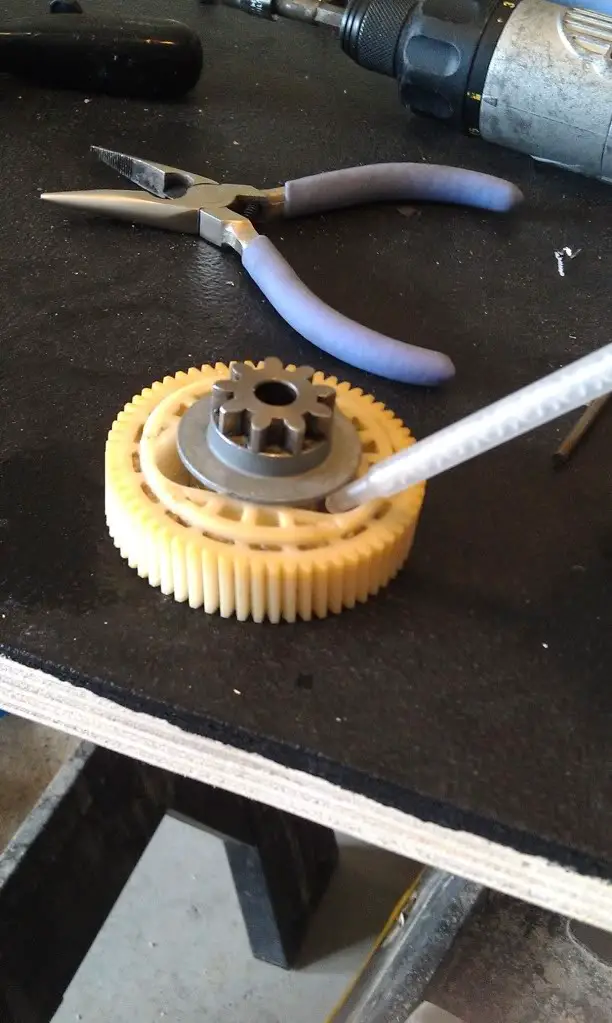

In this picture I am pointing at the actual point of failuer in both my motors. The little nib that looks like it is smashed down is actually where the metal gear is supposed to be crimped and seated. I am guessing that over time the metal gear managed to work itself lose and then proceeded to round out the inside of the plastic gear.

Next step was a good thorough cleaning of both the metal and plastic gears. This part was more per the instructions of the epoxy I was using.

After being cleaned and dried I used the 100 grit sandpaper to rough up the bottom of the metal gear as well as the inside of the plastic gear, again this is per the instructions on the epoxy. This step helps ensure that the epoxy has a good surface to bond to.

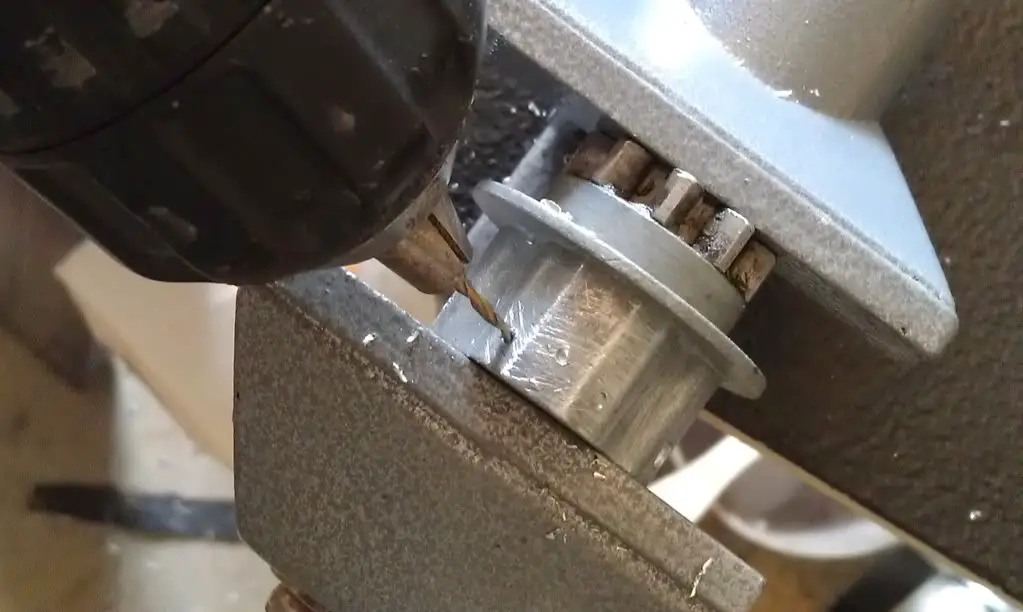

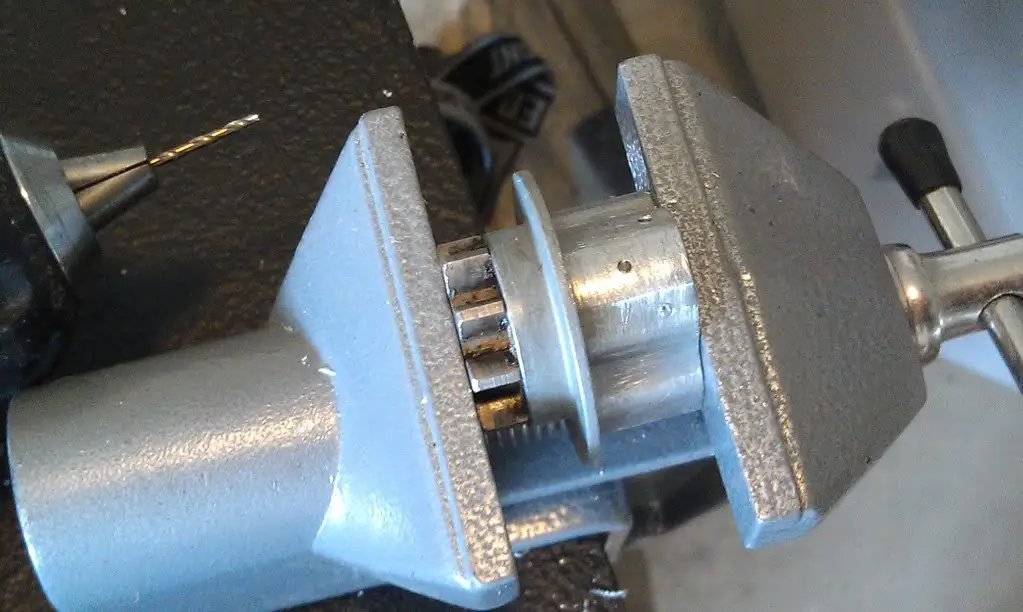

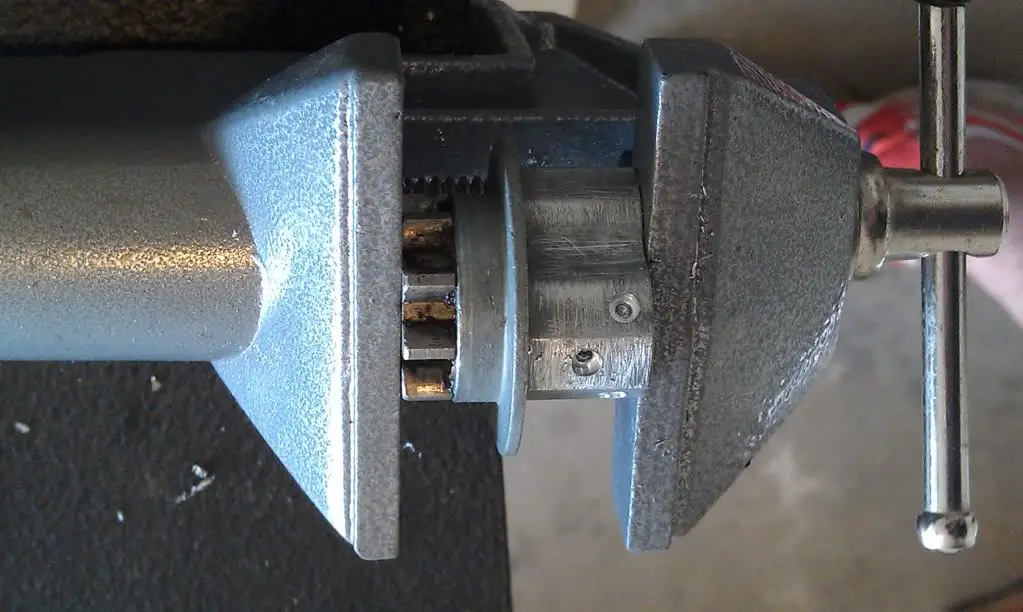

Using my nifty vice I used my drill and the smallest drill bit I had to begin drilling a series of pilot holes around the base of the metal gear. Obviously my plan was to simply epoxy the gears together but I figured by drilling these holes into the gear it would give the epoxy somewhere to settle in a get a good solid bite on the gear.

After using the smallest bit for the pilot holes I went back around and used a slightly larger bit to open up the mouth of all the holes. This again was to simply ensure that the epoxy would flow into these holes and settle in. I took care not to drill too deep into any single place and I only drilled into the meaty portion of the gear so that I didnt sacrifice any of the structural integrity of the little gear itself.

I also used that small drill bit to put a few shallow holes into the inside bottom of the plastic gear to give the epoxy something to grip into. BE CAREFUL NOT TO DRILL ALL THE WAY THROUGH THE PLASTIC GEAR.

This is what the metal gear looked like once I was done drilling all the holes in the base.

After all the drilling was complete I set the gears back together and prepared for the epoxy. It is important to know that when you are putting these gears back together it does not matter how they are aligned together. It only matters that the metal gear sits all the way in to the bottom and seats flat and flush as it did before. Please make sure you clean the plastic gear out completely of any shavings after your sanding and drilling.

This is the epoxy that I chose to use because it has the self-mixing tips that make for pinpoint application and it also has the incredibly high strength rating for the adhesion.

If you look down into the opening between the two gears you can see that I just about filled up the void completely with the epoxy. Also before I placed the metal gear inside the plastic gear I applied a small amount of epoxy to the inside floor of the plastic gear and then pressed the metal gear into its home. Once you have added all the epoxy between the gears give the metal gear a good twist back and forth for a few turns to get the epoxy good and worked in to all the little nooks and crannies you just drilled.

Now just give the gears and epoxy ample time to set and completely harden on a flat surface before you try reinstalling anything. The epoxy I used only took about 5 minutes to completely harden. Once your epoxy has set reassemble the motor the same way you found it. If you have some grease available you might as well throw a little down inside the drive to the motor before closing it up. Dont forget that springy little retaining ring after the gears are in place.

I have attached another short video clip here that shows that my window did in fact work perfectly after this simple repair was completed.

Well thats about it, nothing really to it at all. I really hope this helps at least one person out. I know I saved a few hundred dollars by doing this myself and it only took me about 30 minutes total time to fix each motor. If you have any suggestions or comments please feel free to comment back and let me know, thanks for looking.

Sorry about the giant pictures but I wanted to make sure I could show detail.

I will do my best to explain my way through the pics and how everything was done, but it was actually very simple. Im sure someone out there can make it even easier than this but it sure worked for me. I fixed my first motor almost a month ago and it is used daily and it hasnt even come close to failing on me since I fixed it.

Here are the tools that I used for the repair job; a power drill with small drill bits, 1/16 to 1/8" at the largest. A flat head screw driver, a T-15 Torx driver or bit, a piece of sandpaper, some needlenose pliers, and some type of fast bond epoxy glue (I used Locktite brand), a good vice doesn't hurt to have, and of course there is the Driver side window motor fresh out of my door.

First step was to use the Torx bit to take the cover plate off the motor. As you can see the guts are very simple, all you have is a plastic gear that is driven by the actual motor that is supposed to turn the inner metal gear which actuates the window assembly inside the door.

The gears are held onto the center post by this little ring which I just used some needlenose to remove. BUT BE CAREFUL, THIS LITTLE RETAINER RING IS MIGHTY SPRINGY!!!

Okay once you have removed the retainer ring simply lift the two gears out together as a single unit.

The two gears just come apart. Here you can see how the bottom of the metal gear has an almost "three leaf clover" shape to it.

In this picture I am pointing at the actual point of failuer in both my motors. The little nib that looks like it is smashed down is actually where the metal gear is supposed to be crimped and seated. I am guessing that over time the metal gear managed to work itself lose and then proceeded to round out the inside of the plastic gear.

Next step was a good thorough cleaning of both the metal and plastic gears. This part was more per the instructions of the epoxy I was using.

After being cleaned and dried I used the 100 grit sandpaper to rough up the bottom of the metal gear as well as the inside of the plastic gear, again this is per the instructions on the epoxy. This step helps ensure that the epoxy has a good surface to bond to.

Using my nifty vice I used my drill and the smallest drill bit I had to begin drilling a series of pilot holes around the base of the metal gear. Obviously my plan was to simply epoxy the gears together but I figured by drilling these holes into the gear it would give the epoxy somewhere to settle in a get a good solid bite on the gear.

After using the smallest bit for the pilot holes I went back around and used a slightly larger bit to open up the mouth of all the holes. This again was to simply ensure that the epoxy would flow into these holes and settle in. I took care not to drill too deep into any single place and I only drilled into the meaty portion of the gear so that I didnt sacrifice any of the structural integrity of the little gear itself.

I also used that small drill bit to put a few shallow holes into the inside bottom of the plastic gear to give the epoxy something to grip into. BE CAREFUL NOT TO DRILL ALL THE WAY THROUGH THE PLASTIC GEAR.

This is what the metal gear looked like once I was done drilling all the holes in the base.

After all the drilling was complete I set the gears back together and prepared for the epoxy. It is important to know that when you are putting these gears back together it does not matter how they are aligned together. It only matters that the metal gear sits all the way in to the bottom and seats flat and flush as it did before. Please make sure you clean the plastic gear out completely of any shavings after your sanding and drilling.

This is the epoxy that I chose to use because it has the self-mixing tips that make for pinpoint application and it also has the incredibly high strength rating for the adhesion.

If you look down into the opening between the two gears you can see that I just about filled up the void completely with the epoxy. Also before I placed the metal gear inside the plastic gear I applied a small amount of epoxy to the inside floor of the plastic gear and then pressed the metal gear into its home. Once you have added all the epoxy between the gears give the metal gear a good twist back and forth for a few turns to get the epoxy good and worked in to all the little nooks and crannies you just drilled.

Now just give the gears and epoxy ample time to set and completely harden on a flat surface before you try reinstalling anything. The epoxy I used only took about 5 minutes to completely harden. Once your epoxy has set reassemble the motor the same way you found it. If you have some grease available you might as well throw a little down inside the drive to the motor before closing it up. Dont forget that springy little retaining ring after the gears are in place.

I have attached another short video clip here that shows that my window did in fact work perfectly after this simple repair was completed.

Well thats about it, nothing really to it at all. I really hope this helps at least one person out. I know I saved a few hundred dollars by doing this myself and it only took me about 30 minutes total time to fix each motor. If you have any suggestions or comments please feel free to comment back and let me know, thanks for looking.

Sorry about the giant pictures but I wanted to make sure I could show detail.