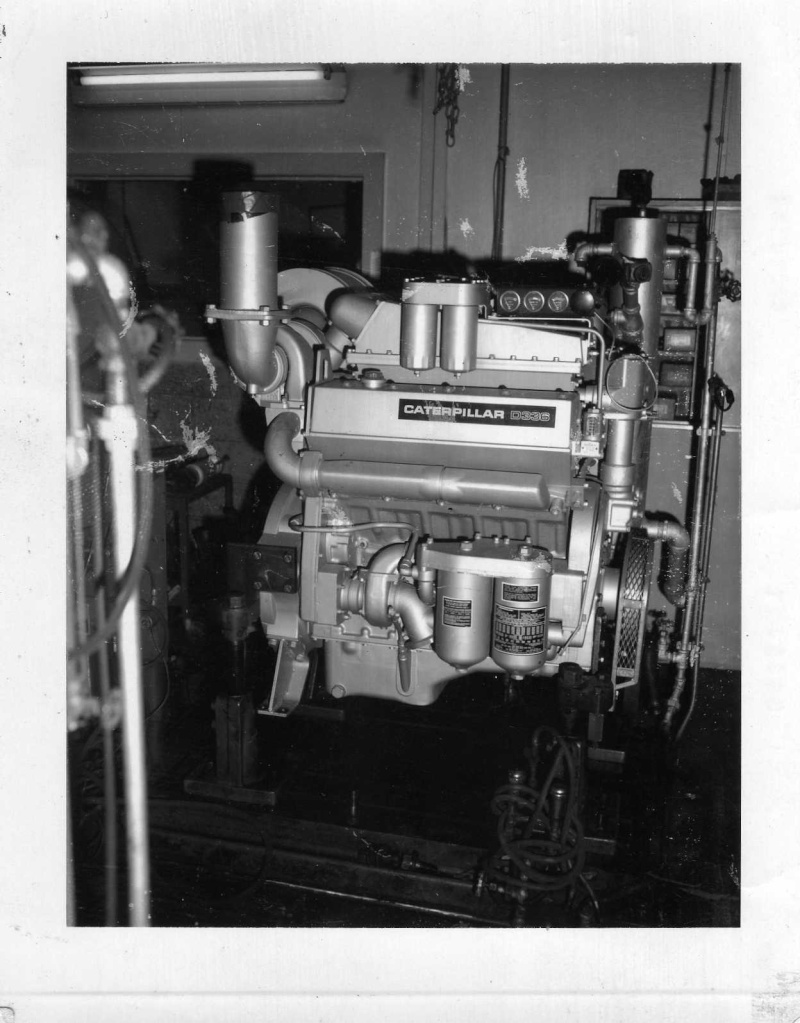

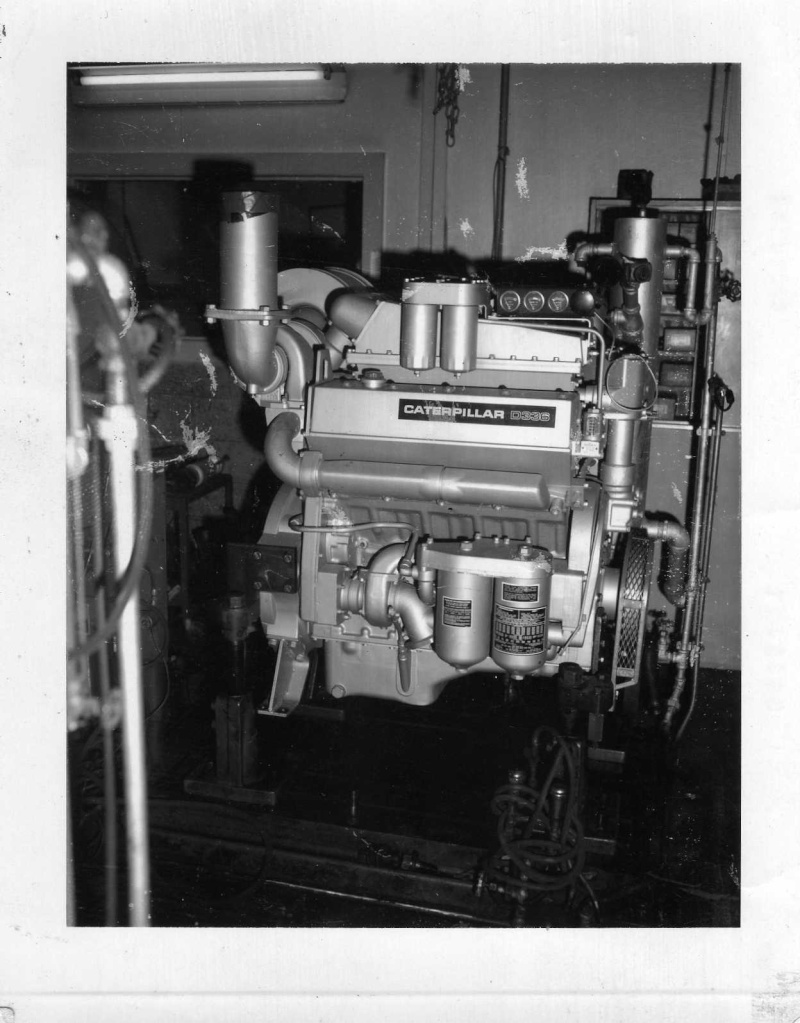

Has anyone successfully designed, built, and tried out a gear-drive retro-fit for chains on these engines? This Cat engine designed for over the road truck use is Dual-overhead cammed, has a maze of gears up front, nary a single chain. Cat knew better, of course. I saw that engine pull rated HP on the dyno stand for weeks on end.

I'm listing what I know here, am open to correction where wrong, can't say "put a roller" here, or some other re-engineering foible, whatever we change will be unproven. I doubt the Germans threw it together without significant amounts of test time. Can we easily make it better?

The Germans in Cologne seem to have used their usual prowess on the 4.0 OHC with lots of chains, and some inaccessible, in Engineering which does get them well-through warranty, but hell with the owner after that, charge him blind to repair/replace. OTOH, not every single one can be said it will fail prematurely, as no one agrees when that is. I've got 165k, another guy has 200k, still quiet. Fixes have included build tensioner pressure quicker, store pressure in bladders, spin an oil pump when key ON at first, etc.

Has anyone replaced the tensioners with spring-loaded devices? Then on to the guides.....evidently early ones failed real often, so "better" guides were used after what, 2003? Metallic guides?

Looks to me like the camshafts are different, one side to the other. What about in the 4.6? Is the valve layout typical Ford EIEIEIEI on both heads, both identical, both turn in the same direction? If heads interchange, first valve up front is different one side to the other. That don't matter, as firing order can take care of that. Since cams for each cylinder are identically-timed for each cylinder, looks like both cams could be identical. But spring-loaded tensioners.

Hell, I don't even know what kind of chains these are. Having heard all my life how timing chains "stretch", and scratched my head many times as a teen-aged grease monkey, I think I understand chains a bit better now. Anyone who has done lots of chain-sawing (I did 20 cords each season in Missouri for 13 years) knows the damned chains are forever losing tension. They are side-linked and pinned. Say a timing chain has 100 links, and each hole has worn bigger by only 0.002", thickness of a human hair, entirely possible, the 100 link length has increased by 0.2", 2/10 of an inch, almost 1/4 inch. Pix look like 100 is too small a number. Think that don't affect timing? A roller-chain should wear less, I THINK, how much less, if so, I dunno. What about sprocket tooth wear?

GEARS are the only realistically-sound way to drive crankshaft-driven overhead camshafts, IMO. What about driving the camshafts directly with a stepping motor? Feasible? Has it ever been done? Could dynamically change timing while running.

Now y'all think I AM nuts! My wife KNOWS........

imp