Here Is how to convert your dome lights from light bulbs to LEDs.

Starting with the Driver and Front Pax

What you will need

20 LEDs 55,000mcd

20 Resistors to bring the voltage down from 12volts to what your LEDs are rated at. Mine were 3.6v

Radio Shack Project board

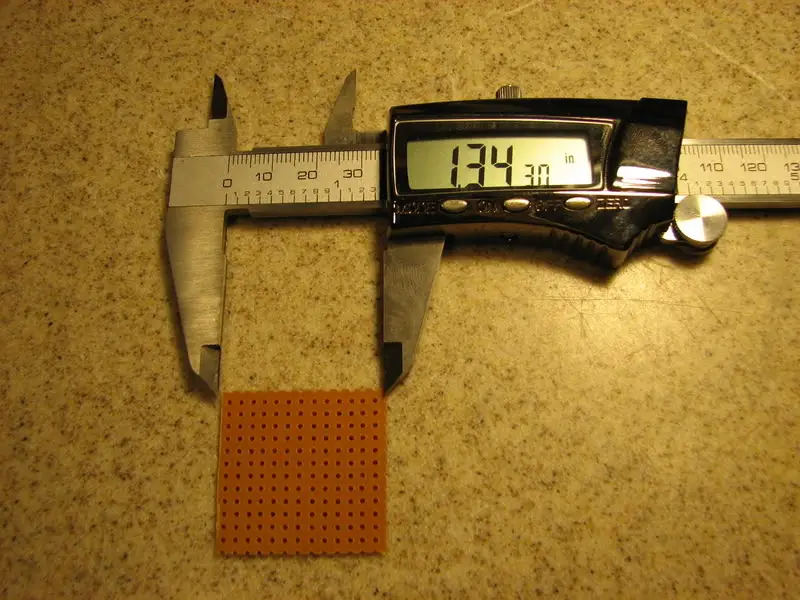

First cut 2 pieces of the project board to 1.35" X1.35"

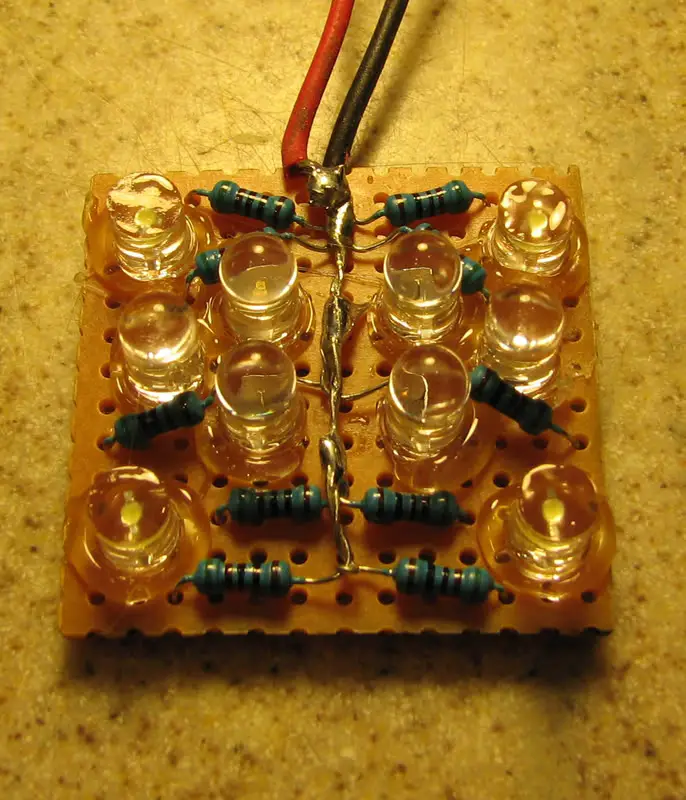

Then arrange your LEDs on the board the way you want them. I used 10 on each board, 6 as spot lights and 4 on the corners as floods (grind the tips flat on the 4). Solder a resistor to each + lead of each LED and wire all the - leads together. Use Hot glue to attach each LED.

Use clear nail polish to refinish the 4 ground down LEDs.

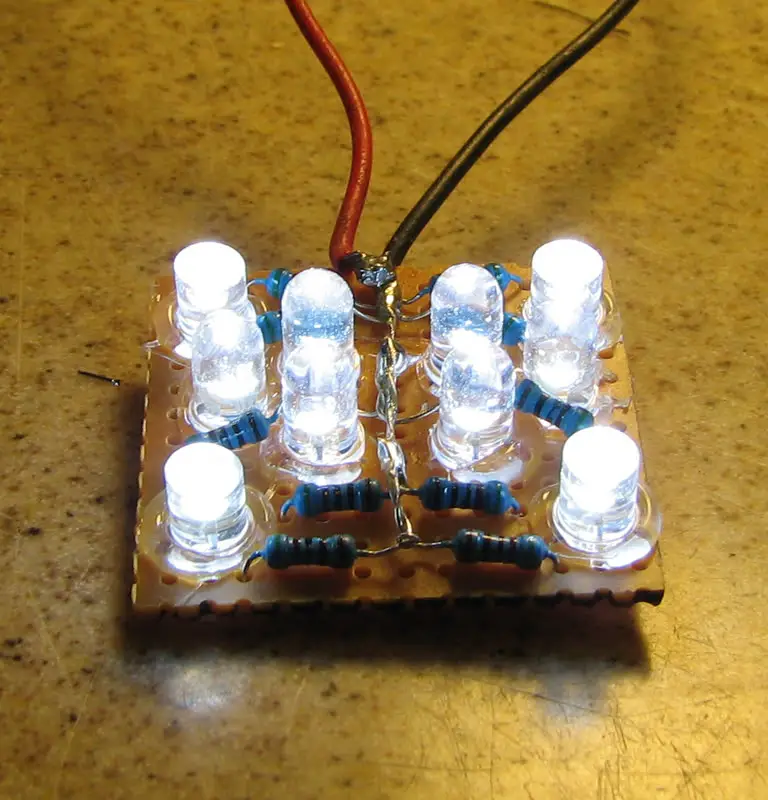

Test

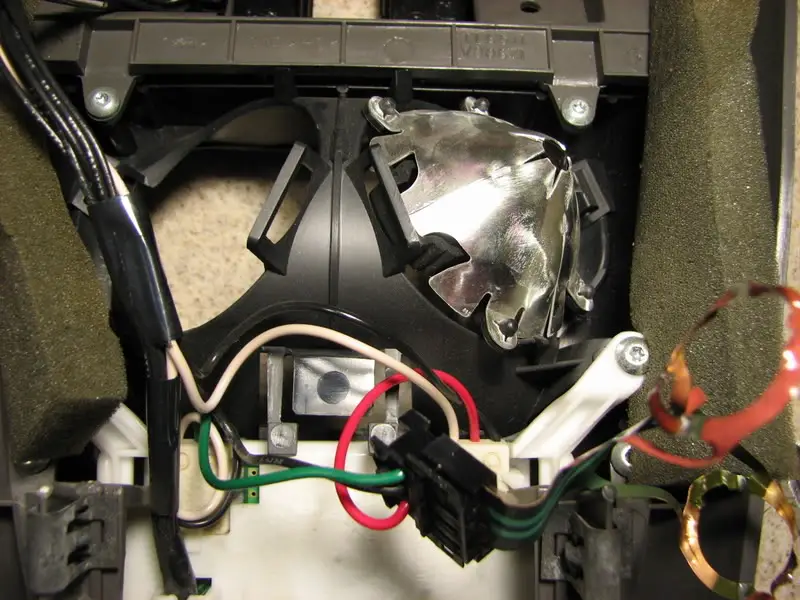

Now disassemble the over head console and remove the 2 bulb holders

Remove the metal shrouds from each of the bulb holders.

Attach each board to the bulb holders using a Zip Tie, then use hot glue of silicone on the back to bond the board to the bulb holder

Wire the 2 boards to the corresponding light switch on the console and snap on the cover.

2nd row seats

I used 8 LEDs for this

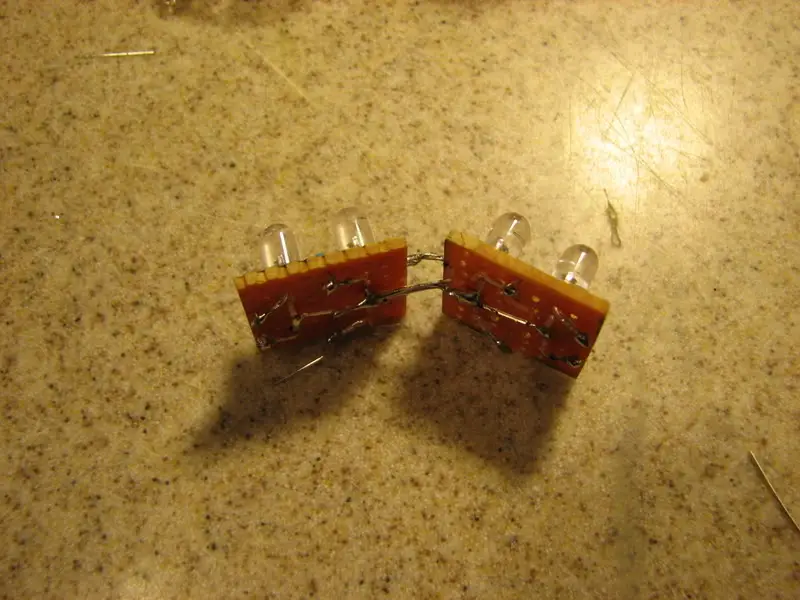

Cut 2 pieces of project board .84"x.84"

Arrange your LEDs and solder away.

I used the - leads on the LEDs to hold the 2 boards together since the dome light reflector is in a pyramid shape and has to be bent in the center.

Hot glue the board in.

Done

Cargo Area

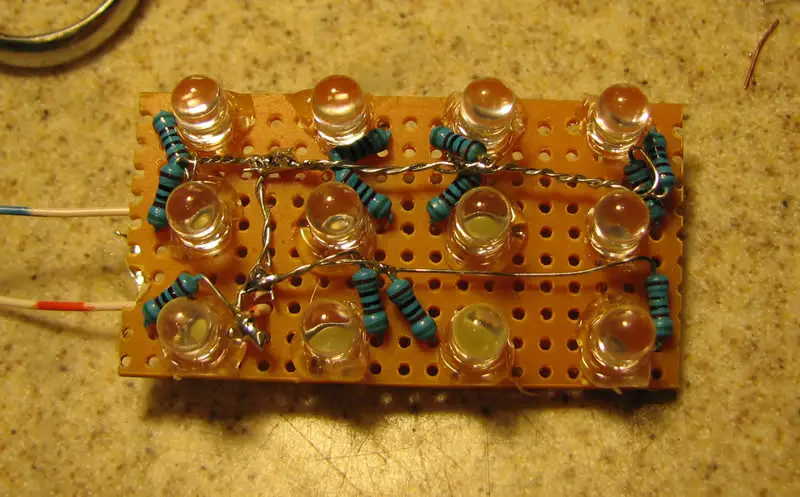

I used 12 LEDs here

After removing the Unit from the headliner you need to gut out the metal contacts that were used for holding the bulb. Then Cut a piece of project board to fit inside the housing. Arrange you the LEDs and solder away.

Here is what the back looks like on the boards with the - leads soldered together.

Use hot glue to glue the board into the housing, and coat back of the board with glue or silicone to insulate.

Done

Will get pics when it gets dark out

Good Luck

Starting with the Driver and Front Pax

What you will need

20 LEDs 55,000mcd

20 Resistors to bring the voltage down from 12volts to what your LEDs are rated at. Mine were 3.6v

Radio Shack Project board

First cut 2 pieces of the project board to 1.35" X1.35"

Then arrange your LEDs on the board the way you want them. I used 10 on each board, 6 as spot lights and 4 on the corners as floods (grind the tips flat on the 4). Solder a resistor to each + lead of each LED and wire all the - leads together. Use Hot glue to attach each LED.

Use clear nail polish to refinish the 4 ground down LEDs.

Test

Now disassemble the over head console and remove the 2 bulb holders

Remove the metal shrouds from each of the bulb holders.

Attach each board to the bulb holders using a Zip Tie, then use hot glue of silicone on the back to bond the board to the bulb holder

Wire the 2 boards to the corresponding light switch on the console and snap on the cover.

2nd row seats

I used 8 LEDs for this

Cut 2 pieces of project board .84"x.84"

Arrange your LEDs and solder away.

I used the - leads on the LEDs to hold the 2 boards together since the dome light reflector is in a pyramid shape and has to be bent in the center.

Hot glue the board in.

Done

Cargo Area

I used 12 LEDs here

After removing the Unit from the headliner you need to gut out the metal contacts that were used for holding the bulb. Then Cut a piece of project board to fit inside the housing. Arrange you the LEDs and solder away.

Here is what the back looks like on the boards with the - leads soldered together.

Use hot glue to glue the board into the housing, and coat back of the board with glue or silicone to insulate.

Done

Will get pics when it gets dark out

Good Luck

... so the visor mirror lights and spot lights were changed back to incandescent bulbs. Dome lights reamin LEDs.

... so the visor mirror lights and spot lights were changed back to incandescent bulbs. Dome lights reamin LEDs.