Well now that Im Elite i figured Id start a thread to document my SAS build...

-

Performance Upgrades - Maintenance - Modifications - Problem Solving - Off-Road - Street Trucks.

Covering the Explorer, ST, Sport, Lincoln Aviator, Sport Trac,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Aerostar.

Featuring H.I. - Human Intelligence.

Register Today It's free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Black Pearl SAS and build

- Thread starter KurtECV

- Start date

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

jprentice94

Well-Known Member

- Joined

- August 11, 2013

- Messages

- 426

- Reaction score

- 4

- Location

- Butte county

- City, State

- oroville ca

- Year, Model & Trim Level

- 91 sas explorer

You could use stock coil buckets even but the limit up travel and coil length my silver one was done unwell this way because the didnt do the ( things in pic above ) I call them jeep di**s or limiting straps and they spaced the axle forward with the coil 2 1/2"

Backward on steel blocks its jank but held 3 years and hour hard travel to work would work great with lower EB mounts and jeep coils

Backward on steel blocks its jank but held 3 years and hour hard travel to work would work great with lower EB mounts and jeep coils

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- November 29, 2000

- Messages

- 10,127

- Reaction score

- 4,076

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

That picture in post 40 is one sloppy SAS, with the coil bucket, shock mounts and panhard mount all at different angles. The tube down the center of the coil springs is something jeep has been doing for years to gain more down travel with shorter coil springs. It works. @Rick used to have his front axle set up that way before he went to coilovers and it worked, but was noisy.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

That picture in post 40 is one sloppy SAS, with the coil bucket, shock mounts and panhard mount all at different angles. The tube down the center of the coil springs is something jeep has been doing for years to gain more down travel with shorter coil springs. It works. @Rick used to have his front axle set up that way before he went to coilovers and it worked, but was noisy.

Yeah I wasn't too worried about the picture just to give guys an idea what I was talking about if I wasn't making sense to them.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

That picture in post 40 is one sloppy SAS, with the coil bucket, shock mounts and panhard mount all at different angles. The tube down the center of the coil springs is something jeep has been doing for years to gain more down travel with shorter coil springs. It works. @Rick used to have his front axle set up that way before he went to coilovers and it worked, but was noisy.

What's your opinion on the way the track bar mount is sitting? I've seen a few guys do it and was thinking that would be a good way to avoid the steering box bolts, or at least incorporate the bolts into the mount

Spudhut

US Navy Submariner

- Joined

- August 14, 2017

- Messages

- 674

- Reaction score

- 228

- Location

- NW Arkansas

- City, State

- Bentonville, AR

- Year, Model & Trim Level

- 1997 Explorer Sport - 4x4

- Callsign

- KG5SPB

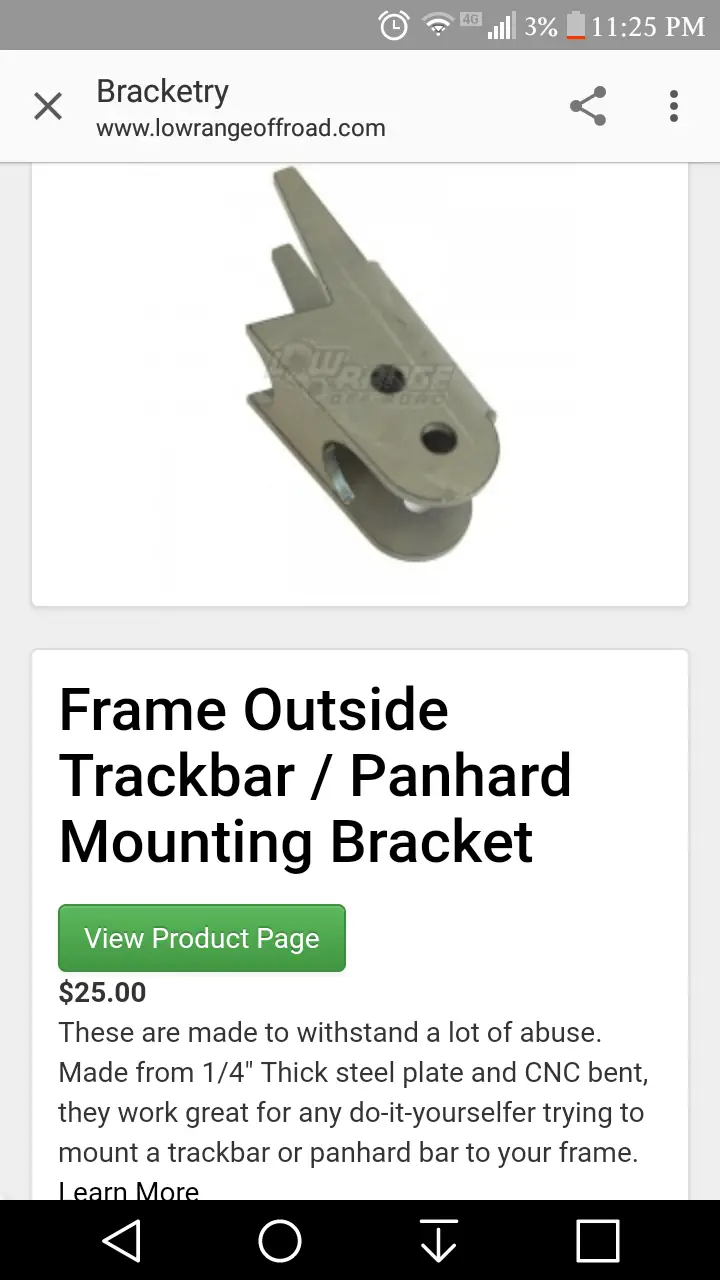

It appears the track bar mount is bending or being pulled downward. I don't understand why the bracket has a hole, it should have had a full piece of plate to strengthen it.

Using the existing bolts in the frame are a good idea, as long as the geometry is correct.

Using the existing bolts in the frame are a good idea, as long as the geometry is correct.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

that hole is to gain access to the rear-most bolt for the steering box. depending on the geometry and axle placement that may be unavoidable for some... im thinking thats what will have to be done with mine as well.

or i may run it just forward of that bolt, enough to be able to lay a solid weld and still be able to remove the bolt... track bar is the last of my worries right now but everything has to be considered throughout the build.

or i may run it just forward of that bolt, enough to be able to lay a solid weld and still be able to remove the bolt... track bar is the last of my worries right now but everything has to be considered throughout the build.

Spudhut

US Navy Submariner

- Joined

- August 14, 2017

- Messages

- 674

- Reaction score

- 228

- Location

- NW Arkansas

- City, State

- Bentonville, AR

- Year, Model & Trim Level

- 1997 Explorer Sport - 4x4

- Callsign

- KG5SPB

"that hole is to gain access to the rear-most bolt for the steering box. depending on the geometry and axle placement"

I didn't even see that...you could plate it all the way through, then add a hole big enough for socket to fit and press a bevel on it for added strength....

Believe me, I understand your thought on the bars, I'm in the process of figuring out my 3-link conversion geometry for my Gen2...(I have read so much on the concept, my brain is toast - I cant read another thread on the subject - its so convoluted, I wish someone would post some spec's on their builds to give a good but rough idea on their successes

- I cant read another thread on the subject - its so convoluted, I wish someone would post some spec's on their builds to give a good but rough idea on their successes  .)...its amazing how a simple add to your vehicle can be the most involved

.)...its amazing how a simple add to your vehicle can be the most involved

I didn't even see that...you could plate it all the way through, then add a hole big enough for socket to fit and press a bevel on it for added strength....

Believe me, I understand your thought on the bars, I'm in the process of figuring out my 3-link conversion geometry for my Gen2...(I have read so much on the concept, my brain is toast

- I cant read another thread on the subject - its so convoluted, I wish someone would post some spec's on their builds to give a good but rough idea on their successes

- I cant read another thread on the subject - its so convoluted, I wish someone would post some spec's on their builds to give a good but rough idea on their successes  .)...its amazing how a simple add to your vehicle can be the most involved

.)...its amazing how a simple add to your vehicle can be the most involved- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

the problem with each build is that they are always different, there are about a dozen or so builds that i can going off of for my build, not just one specifically.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

awesome little update:

i have used C&M Gear Works in Springfield, MO to get a few odds and ends parts for the Dana 44 and they usually ship quickly (cause my work hours are the same as theirs i always have them ship me stuff) and i called this afternoon to get a pinion bearing baffle and it was only $1.85 plus shipping and i went to give Chris my credit card info and he said not to worry about it cause ive ordered stuff before... how awesome is that?? The baffle should be here tomorrow or friday so i cant get the gears and axles back into the 44

i have used C&M Gear Works in Springfield, MO to get a few odds and ends parts for the Dana 44 and they usually ship quickly (cause my work hours are the same as theirs i always have them ship me stuff) and i called this afternoon to get a pinion bearing baffle and it was only $1.85 plus shipping and i went to give Chris my credit card info and he said not to worry about it cause ive ordered stuff before... how awesome is that?? The baffle should be here tomorrow or friday so i cant get the gears and axles back into the 44

- Joined

- November 29, 2000

- Messages

- 10,127

- Reaction score

- 4,076

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

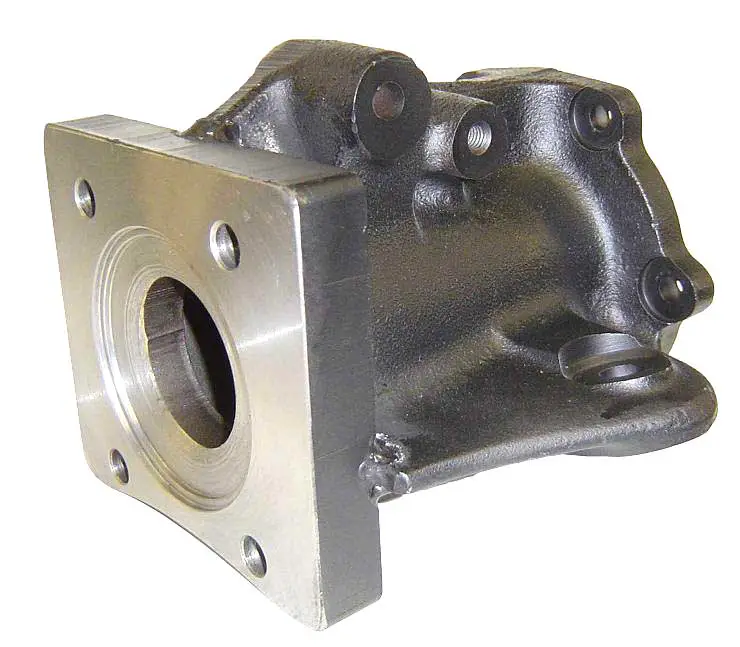

Here is my track bar mount. Crappy pictures, but you can see the rear steering gear box bolt in the hole cut out of the mount. In the final version, I had to drop the bracket about three inches to get the track bar on the same angle as the drag link so I built off the original mount instead of cutting it off. It made for a much stronger mount because its double thickness for all of the length below the frame, and plug welded through the original holes. I also welded a piece of 1" OD, 1/4" wall DOM tube from the bottom half of the mount up to the engine cross member that you can see in the second picture.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

thats awesome. i was thinking about building a cross-member/brace from the passenger side frame, ive seen a few guys on here do it but a lot of heep guys do it.

i will have to wait to dig into the track bar til i get the axle under it to see where the track bar mount will be going. ive got a ballistic fab adjustable frame side 2.0" track bar mount that will most likely get used, but until then ill keep working away on the Dana 44, if i can get the weather to be above freezing that would be nice. Might bring the axle to work and steal the tranny bench for a bit, the shop stays 70 degrees thanks to a waste oil heater bolted to the ceiling

i will have to wait to dig into the track bar til i get the axle under it to see where the track bar mount will be going. ive got a ballistic fab adjustable frame side 2.0" track bar mount that will most likely get used, but until then ill keep working away on the Dana 44, if i can get the weather to be above freezing that would be nice. Might bring the axle to work and steal the tranny bench for a bit, the shop stays 70 degrees thanks to a waste oil heater bolted to the ceiling

- Joined

- November 29, 2000

- Messages

- 10,127

- Reaction score

- 4,076

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

thats awesome. i was thinking about building a crossmember/brace from the passenger side frame, ive seen a few guys on here do it but a lot of heep guys

Rock Ranger ran a cross brace to the opposite frame rail, but I have clearance issues with the HP D44. I ended up cutting out the engine cross member just past the engine mounts and making a new bolt-in piece that sits higher. Did that for two reasons; one for clearance, the other for access to the engine oil pan.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

Rock Ranger ran a cross brace to the opposite frame rail, but I have clearance issues with the HP D44. I ended up cutting out the engine cross member just past the engine mounts and making a new bolt-in piece that sits higher. Did that for two reasons; one for clearance, the other for access to the engine oil pan.

Got any pictures of your setup? There aren't many floating around anymore

- Joined

- November 29, 2000

- Messages

- 10,127

- Reaction score

- 4,076

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

The process I went through to remove and build a new engine cross member starts on page 61 of my build thread. There is other stuff mixed in about steering issues.

Bkennedy's SAS and Rebuild Thread

Bkennedy's SAS and Rebuild Thread

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

if the temps would get above 20 degrees id be getting that axle under the truck. i was hoping to get some work done this weekend but apparently there is a cold front coming in that supposed to last the weekend (thats my luck).

anyone have a pinion depth gauge they wanna let me borrow lol. i work for GM and we have the gauge for the Dana 60s; i am not sure if that will work or not i havent found info saying they will. anyone have any input?

anyone have a pinion depth gauge they wanna let me borrow lol. i work for GM and we have the gauge for the Dana 60s; i am not sure if that will work or not i havent found info saying they will. anyone have any input?

Spudhut

US Navy Submariner

- Joined

- August 14, 2017

- Messages

- 674

- Reaction score

- 228

- Location

- NW Arkansas

- City, State

- Bentonville, AR

- Year, Model & Trim Level

- 1997 Explorer Sport - 4x4

- Callsign

- KG5SPB

Hah...i hear ya....looks like its going to be that way for a few more days...and my gas heater just broke

- Joined

- August 1, 2008

- Messages

- 11,764

- Reaction score

- 2,135

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

Going to have the Coldest NYE in 30 yrs, with -5* below, and saying the 4th coldest overall.

It's going to warm up to 35* this afternoon for a couple hours. Just enough to tease you, and not enough time to do anything really. Might as well put the build on pause until spring has sprung. lol

It's going to warm up to 35* this afternoon for a couple hours. Just enough to tease you, and not enough time to do anything really. Might as well put the build on pause until spring has sprung. lol

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

yeah i picked up a little propane hotspot the other week, just haven't picked up a tank yet. also i need to insulate my one car shop a little better from the previous owner.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

Going to have the Coldest NYE in 30 yrs, with -5* below, and saying the 4th coldest overall.

It's going to warm up to 35* this afternoon for a couple hours. Just enough to tease you, and not enough time to do anything really. Might as well put the build on pause until spring has sprung. lol

i am more stubborn than that to let a little frostbite stop this build til the temps are higher than my age

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- November 29, 2000

- Messages

- 10,127

- Reaction score

- 4,076

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

Hmmmmmmmmmm, its 80* here today. Unusually warm, usually its in the high 60's to low 70's this time of year...

Similar Threads

- Article

- Replies

- 216

- Views

- 33,909