2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,597

- Reaction score

- 334

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

spark adders

According to Advantage Help, Ford Tuning, Spark:

"In addition you will want to make sure you set SPK_ADJ_FOR_EMISSIONS and SPARK_ADJ_FOR_COMBUSTION_NOISE to all zeros. You cannot do this on a supercharged engine. You cannot put MBT spark everywhere and expect the air temp sensor to be able to compensate for it. In these cases you will need to lower the BORDERLINE_KNOCK_TABLE to compensate for the spark requirements.

In this version of spark there are two other parameters of interest, SPARK_GLOBAL_ADDER and SPARK_GLOBAL MULTIPLIER. These values allow you to override the above calculations and just add in spark to the final calculation. It does not check it against the base table; it just adds it to the final amount. The SPARK_GLOBAL MULTIPLIER multiplies the final spark value by whatever that multiplier is."

I don't know if all of the above apply for your strategy but I suggest you check them.

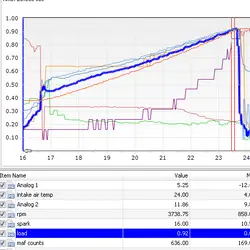

By the way, for your posted Borderline Knock Table at 3500 rpm the spark is 39 for load = .3 and 14 for load = .4. That means if the load is .35 the BKT spark will be 26.5 {[(39-14)/2]+14}. What was your logged load when your spark was 19 deg at 3500 rpm and 2 psi boost?

I made some good progress. . . I'm still seeing more timing that I am commanding in the borderline spark table. I'm not hearing any detonation, and at the top end I'm down to 13.75 degree's. Still at 3500rpm and 2 lbs boost I'm seeing 19 degrees. Not horrible, but I better learn my spark tables. . .

According to Advantage Help, Ford Tuning, Spark:

"In addition you will want to make sure you set SPK_ADJ_FOR_EMISSIONS and SPARK_ADJ_FOR_COMBUSTION_NOISE to all zeros. You cannot do this on a supercharged engine. You cannot put MBT spark everywhere and expect the air temp sensor to be able to compensate for it. In these cases you will need to lower the BORDERLINE_KNOCK_TABLE to compensate for the spark requirements.

In this version of spark there are two other parameters of interest, SPARK_GLOBAL_ADDER and SPARK_GLOBAL MULTIPLIER. These values allow you to override the above calculations and just add in spark to the final calculation. It does not check it against the base table; it just adds it to the final amount. The SPARK_GLOBAL MULTIPLIER multiplies the final spark value by whatever that multiplier is."

I don't know if all of the above apply for your strategy but I suggest you check them.

By the way, for your posted Borderline Knock Table at 3500 rpm the spark is 39 for load = .3 and 14 for load = .4. That means if the load is .35 the BKT spark will be 26.5 {[(39-14)/2]+14}. What was your logged load when your spark was 19 deg at 3500 rpm and 2 psi boost?