- Joined

- February 8, 2003

- Messages

- 9,824

- Reaction score

- 84

- City, State

- Sacramento, CA 95827

- Year, Model & Trim Level

- 1992 XLT

Engine Sensors - Part 1 Oxygen Sensors

Oxygen Sensors…. One of the most misunderstood parts of today’s modern automotive engines. Also the part that is most often associated as being "bad" by the general population when they see a “check engine” light (sometimes labeled “Service engine” or “MIL”). What are hey? How are they made? How do they work? What do they do? What does Closed loop mean? What if I get a "check engine" light relating to an O2 sensor? I hope by the time you get done reading SENSORS – PART ONE, you’ll know.

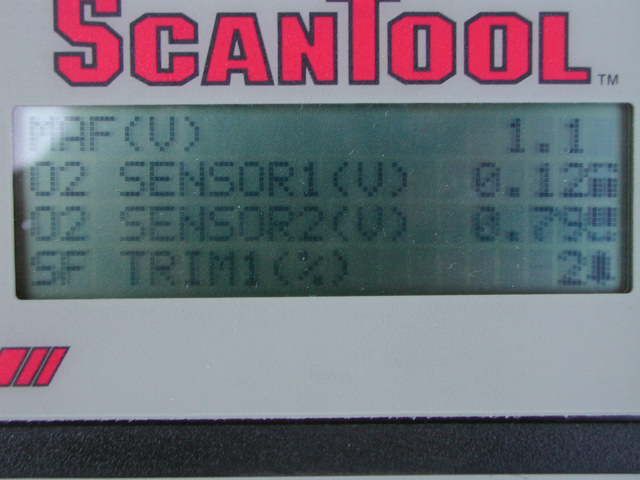

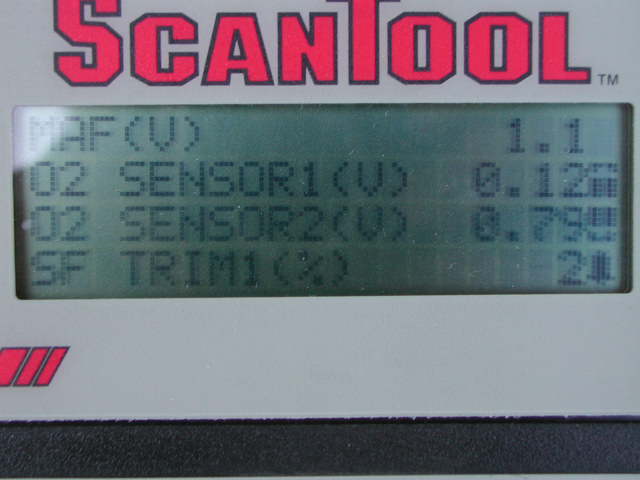

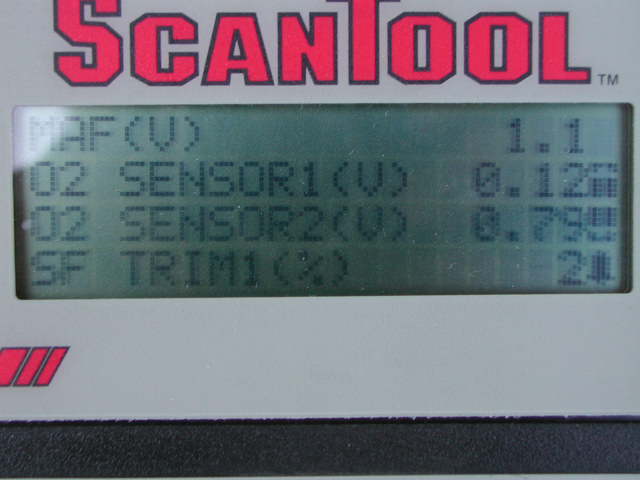

What are they? Oxygen sensors measure the oxygen content of exhaust gases. Nothing more complicated than that. They report the amount of oxygen as a voltage – they output a generated voltage (the exception being titania sensors, discussed below). A rich mixture has more unused oxygen in it, and the sensor will output up to about .9 volts in that condition. A lean condition will have less unused oxygen in it. The sensor will output much less voltage in that situation, down around .1 volts. They are used to provide feedback to the auto’s computer to tell it when to enrich, and when to lean the fuel mixture. [Which it does by lengthening or shortening the time the fuel injectors are open – pulse width it is called]. Practically speaking, what this means is that the computer is chasing the cat’s tail constantly. Too rich, too lean, and so on and so forth. This back and forth of the mixture produces a sinusoidal wave (well kinda) out of a healthy 02 sensor. The “perfect” air/fuel ratio is considered to be 14.7 parts air to 1 part fuel, sometimes seen as 14.7:1 or called Lambda in the parlance of the Society of Automotive Engineers (SAE). Do you remember the late 70’s Volvo with a “Lambda sensor” Now you know what it was. The first 02 sensor. Back to the wave. It will vary between about .2 and .8 volts crossing over the “Lambda” voltage (which happens to be .445 V) about 2 – 8 times a second for a healthy sensor on a multiport engine... speed varies depending on the type of fuel injection – feedback carburetors being slowest (and almost extinct) throttle body injection the next slowest and multi port the fastest. Here is a picture of a scanner readout of a 4 O2 sensor engine.....reading bank 1 and bank 2... you can see that one bank is rich and one is lean, which one is which?

then, taken immediately after

see the change?

How are they made? There are two designs of sensors. One, which we will not discuss is the Titania sensor, and instead of creating a varying voltage offers a varying resistance. Jeep and some imports use it. The other is a Zirconia sensor, which produces a voltage. This is the one we will discuss. Zirconia Oxygen sensors consist of a bulb, which is part of an assembly which screws into the exhaust manifold so the bulb is in the exhaust stream. The bulb is either made of or contains zirconium ceramic. Inside the bulb are platinum electrode(s). The bulb itself has slits in it so that the inside vents to the outside and exhaust gases pass through it. That is the basic construction. Oh, maybe this is a good place to note something. Fastest way to kill an O2 sensor? Silicone. Spray a silicone spray into the intake of a modern engine and your O2 sensors will die in a heartbeat. Ever wondered what it means when you see products labeled “O2 sensor safe?” It just means there is no silicone.

Here is a sensor for a 92 Explorer:

How do they work? Well actually I think this is pretty well answered above. I cannot tell you the chemistry or physics, so I guess continuing this one is kind of pointless, other than to note that heat is the important factor (but I understand NOT the only factor), so they closely track exhaust gas temperature, which also varies based on A/F ratios. (In fact aircraft engines are adjusted for proper A/F ratios by adjusting mixture observing exhaust gas temps in fact since they do not have fixed injector pulse widths or carburetors). Anyway the best thing I can tell you is O2 sensors do work, and do it well. How long? Well in many cases hundred thousand miles or even two hundred thousand miles. As they age, deposits build up and they get slower in their crossover rates, and this can affect fuel efficiency. Expect 75,000 miles easily provided your engine is running ok, and no one is running around with a can of silicone spray nearby and no one has used silicone seal on gaskets in the engine.

What do they do? When they first arrived on the scene, engineers tended to use a single O2 sensor to feedback to the computer to adjust air/fuel (sometimes referred to as A/F) ratio. Later as emissions relied more heavily on the Catalytic Convertor (CAT), we added one AFTER the convertor, the idea being that the after CAT (or post CAT) O2 sensor would not vary as much in output voltage since the CAT should have used up most of the oxygen…. So the output should be “lean” or at least switch much less. Here’s a quiz – what do you think the output voltage on a post-cat O2 sensor will be closer to? .1 V or .8 V? If you do not know, go back and re-read the beginning.

As we moved into more sophisticated systems, we added more sensors, including O2 sensors. Now we sport four O2 sensors in most cases, one on each bank, before the CAT and one after (post) CAT.

Open Loop or Closed Loop? An engineer will tell you that a system which uses output feedback to control its operation is considered a “closed loop” system. One which does not is “open loop”. We know that an O2 sensor runs on heat. An engine in startup does not produce enough heat to make them work. SO…. On startup, the engine computer fuel system runs in “open loop”… and utilizes stored information to provide fuel metering. Once the O2 sensors get warm enough to start operating, the system switches over the them, and into “closed loop”. Starting in the mid 90’s we added heaters to the sensors to speed up this process, since closed loop was friendlier to emissions. Thus the Exhaust Gas Oxygen Sensor, or EGO sensor became “heated” and is now called the Heated Exhaust Gas Oxygen sensor or HEGO sensor. When people see HEGO sometimes they get all confused. It is just the Oxygen Sensor, with heat. Heated sensors usually have 4 wires, non heated 1 or 2.

What does it mean when I get an O2 Sensor Diagnostic Trouble Code (DTC)? The computer watches the performance of the sensors. For example, if pre-CAT sensors stay above or below the .445V it sees this and will set a code, either rich or lean depending. Does that mean the sensors are bad? NO! It means in about 99% of the cases that the sensors are reporting a condition that is either RICH or LEAN, that’s all. Now WHY… is up to you. Lean is often a vacuum leak, and rich is often fuel pressure or intake air related. So if you get a code involving “O2 sensors indicate lean, bank 1” do not assume your sensor is bad and replace it. That would be like having a scout come back and tell you “Sir, the enemy is 5 miles ahead in numbers” and shooting him because you didn’t like hearing his message. (This is a little simplified but you get my idea here how this works, right?)

How do I remove them? Well, truth is they can be real buggers to get out. You may want to try and spray them with penetrating oil, remembering that it will smoke until it burns off once you start up again. They have a wire coming out of the end, so an ordinary socket won;t do, you need a special tool. Here are two. A silver aftermarket one, and the FORD Rotunda tool made by Owatonna Tool Company, or OTC (quality stuff).

here is the OTC one in my hand, sharp eyes may notice the year and number, which until recently was how OTC identified their tools for FORD. When you have room, this one seems to work best, but sometimes a straight shot with the other one is all you can get. The wires go into the slots, in case you wondered.

I am sure I will think of more to add to this, but this seemed like a good start on the sensor series. For those of you for whom this may have saved $75 by NOT replacing a perfectly good O2 sensor, why not use $20 of that and become an Elite explorer and "join" this site? No, ok, then how about buying me a cold one someday? Or better yet... both?

Oxygen Sensors…. One of the most misunderstood parts of today’s modern automotive engines. Also the part that is most often associated as being "bad" by the general population when they see a “check engine” light (sometimes labeled “Service engine” or “MIL”). What are hey? How are they made? How do they work? What do they do? What does Closed loop mean? What if I get a "check engine" light relating to an O2 sensor? I hope by the time you get done reading SENSORS – PART ONE, you’ll know.

What are they? Oxygen sensors measure the oxygen content of exhaust gases. Nothing more complicated than that. They report the amount of oxygen as a voltage – they output a generated voltage (the exception being titania sensors, discussed below). A rich mixture has more unused oxygen in it, and the sensor will output up to about .9 volts in that condition. A lean condition will have less unused oxygen in it. The sensor will output much less voltage in that situation, down around .1 volts. They are used to provide feedback to the auto’s computer to tell it when to enrich, and when to lean the fuel mixture. [Which it does by lengthening or shortening the time the fuel injectors are open – pulse width it is called]. Practically speaking, what this means is that the computer is chasing the cat’s tail constantly. Too rich, too lean, and so on and so forth. This back and forth of the mixture produces a sinusoidal wave (well kinda) out of a healthy 02 sensor. The “perfect” air/fuel ratio is considered to be 14.7 parts air to 1 part fuel, sometimes seen as 14.7:1 or called Lambda in the parlance of the Society of Automotive Engineers (SAE). Do you remember the late 70’s Volvo with a “Lambda sensor” Now you know what it was. The first 02 sensor. Back to the wave. It will vary between about .2 and .8 volts crossing over the “Lambda” voltage (which happens to be .445 V) about 2 – 8 times a second for a healthy sensor on a multiport engine... speed varies depending on the type of fuel injection – feedback carburetors being slowest (and almost extinct) throttle body injection the next slowest and multi port the fastest. Here is a picture of a scanner readout of a 4 O2 sensor engine.....reading bank 1 and bank 2... you can see that one bank is rich and one is lean, which one is which?

then, taken immediately after

see the change?

How are they made? There are two designs of sensors. One, which we will not discuss is the Titania sensor, and instead of creating a varying voltage offers a varying resistance. Jeep and some imports use it. The other is a Zirconia sensor, which produces a voltage. This is the one we will discuss. Zirconia Oxygen sensors consist of a bulb, which is part of an assembly which screws into the exhaust manifold so the bulb is in the exhaust stream. The bulb is either made of or contains zirconium ceramic. Inside the bulb are platinum electrode(s). The bulb itself has slits in it so that the inside vents to the outside and exhaust gases pass through it. That is the basic construction. Oh, maybe this is a good place to note something. Fastest way to kill an O2 sensor? Silicone. Spray a silicone spray into the intake of a modern engine and your O2 sensors will die in a heartbeat. Ever wondered what it means when you see products labeled “O2 sensor safe?” It just means there is no silicone.

Here is a sensor for a 92 Explorer:

How do they work? Well actually I think this is pretty well answered above. I cannot tell you the chemistry or physics, so I guess continuing this one is kind of pointless, other than to note that heat is the important factor (but I understand NOT the only factor), so they closely track exhaust gas temperature, which also varies based on A/F ratios. (In fact aircraft engines are adjusted for proper A/F ratios by adjusting mixture observing exhaust gas temps in fact since they do not have fixed injector pulse widths or carburetors). Anyway the best thing I can tell you is O2 sensors do work, and do it well. How long? Well in many cases hundred thousand miles or even two hundred thousand miles. As they age, deposits build up and they get slower in their crossover rates, and this can affect fuel efficiency. Expect 75,000 miles easily provided your engine is running ok, and no one is running around with a can of silicone spray nearby and no one has used silicone seal on gaskets in the engine.

What do they do? When they first arrived on the scene, engineers tended to use a single O2 sensor to feedback to the computer to adjust air/fuel (sometimes referred to as A/F) ratio. Later as emissions relied more heavily on the Catalytic Convertor (CAT), we added one AFTER the convertor, the idea being that the after CAT (or post CAT) O2 sensor would not vary as much in output voltage since the CAT should have used up most of the oxygen…. So the output should be “lean” or at least switch much less. Here’s a quiz – what do you think the output voltage on a post-cat O2 sensor will be closer to? .1 V or .8 V? If you do not know, go back and re-read the beginning.

As we moved into more sophisticated systems, we added more sensors, including O2 sensors. Now we sport four O2 sensors in most cases, one on each bank, before the CAT and one after (post) CAT.

Open Loop or Closed Loop? An engineer will tell you that a system which uses output feedback to control its operation is considered a “closed loop” system. One which does not is “open loop”. We know that an O2 sensor runs on heat. An engine in startup does not produce enough heat to make them work. SO…. On startup, the engine computer fuel system runs in “open loop”… and utilizes stored information to provide fuel metering. Once the O2 sensors get warm enough to start operating, the system switches over the them, and into “closed loop”. Starting in the mid 90’s we added heaters to the sensors to speed up this process, since closed loop was friendlier to emissions. Thus the Exhaust Gas Oxygen Sensor, or EGO sensor became “heated” and is now called the Heated Exhaust Gas Oxygen sensor or HEGO sensor. When people see HEGO sometimes they get all confused. It is just the Oxygen Sensor, with heat. Heated sensors usually have 4 wires, non heated 1 or 2.

What does it mean when I get an O2 Sensor Diagnostic Trouble Code (DTC)? The computer watches the performance of the sensors. For example, if pre-CAT sensors stay above or below the .445V it sees this and will set a code, either rich or lean depending. Does that mean the sensors are bad? NO! It means in about 99% of the cases that the sensors are reporting a condition that is either RICH or LEAN, that’s all. Now WHY… is up to you. Lean is often a vacuum leak, and rich is often fuel pressure or intake air related. So if you get a code involving “O2 sensors indicate lean, bank 1” do not assume your sensor is bad and replace it. That would be like having a scout come back and tell you “Sir, the enemy is 5 miles ahead in numbers” and shooting him because you didn’t like hearing his message. (This is a little simplified but you get my idea here how this works, right?)

How do I remove them? Well, truth is they can be real buggers to get out. You may want to try and spray them with penetrating oil, remembering that it will smoke until it burns off once you start up again. They have a wire coming out of the end, so an ordinary socket won;t do, you need a special tool. Here are two. A silver aftermarket one, and the FORD Rotunda tool made by Owatonna Tool Company, or OTC (quality stuff).

here is the OTC one in my hand, sharp eyes may notice the year and number, which until recently was how OTC identified their tools for FORD. When you have room, this one seems to work best, but sometimes a straight shot with the other one is all you can get. The wires go into the slots, in case you wondered.

I am sure I will think of more to add to this, but this seemed like a good start on the sensor series. For those of you for whom this may have saved $75 by NOT replacing a perfectly good O2 sensor, why not use $20 of that and become an Elite explorer and "join" this site? No, ok, then how about buying me a cold one someday? Or better yet... both?