JonathanExp

Elite Explorer

- Joined

- August 26, 2018

- Messages

- 36

- Reaction score

- 23

- City, State

- USA living in AUS

- Year, Model & Trim Level

- 2002 explorer limited

here are my pics and my write up for a 3rd gen 12v/120v power panel in place of the rear sub woofer.

i removed my factory sub woofer when i first purchased the truck and installed a custom sub/amp set up in the floor (possible write up one day) so it has been an unused area for years. since moving to Australia, where most 4x4s have fridges in the back, i wanted to install a more permanent solution for providing power to the fridge. behind the panel, i also installed the cb/uhf radio, the 12v/120v power converter, and the switch/power box for my roof lights (write up coming). the power for the set up comes from my main battery and my second battery (3rd Gen Dual Battery Setup). this project took many days to complete but it was fun.

there is a fair amount of room once the sub is removed.

i started by removing the factory grill. just have to pick/cut away at the melted plastic attachment points holding it on.

next, i traced out the factory grill on a piece of 12mm thick mdf. sand down the perimeter to get close to the factory grill design so it comes in flush with the side panel.

test fit the panel.

more test fitting.

you need to create some depth to protect the wires coming out in the front but clearance for the electronics and wires behind. roughly 1 1/8" width trim board with 6mm mdf for the back board.

this is the layout i wanted for my electronics. flush mount the screws so you can fill the holes with wood putty. (i later remade this board to swap the 120v and anderson plug locations as the 120v outlet cover could not be open with the plastic window shut)

back side shot. two takeaways here - i premounted the blocks on the sides first, screwing them in from the front then installing the panel and putting in screws to the sides to hold the panel (the blocks have an angle to fit flush on the wood panel). i also installed blocking on the back to give the fuse panel and anderson connector something to screw into securely.

test fit of the smoked plastic panel. cut and sanded to fit. the opening at the bottom is to allow the wires to come out with the plastic window shut.

lots of glue, screws, wood putty, sanding, paint, fiberglass resin, and more paint. i took the factory grill to the local paint/box store and they matched the color for me after telling me the paint is not designed for car use. :-| after a primer coat, i applied one color coat then coated it twice with fiberglass resin to add some scratch resistance, sanded it and added maybe two more layers of color paint.

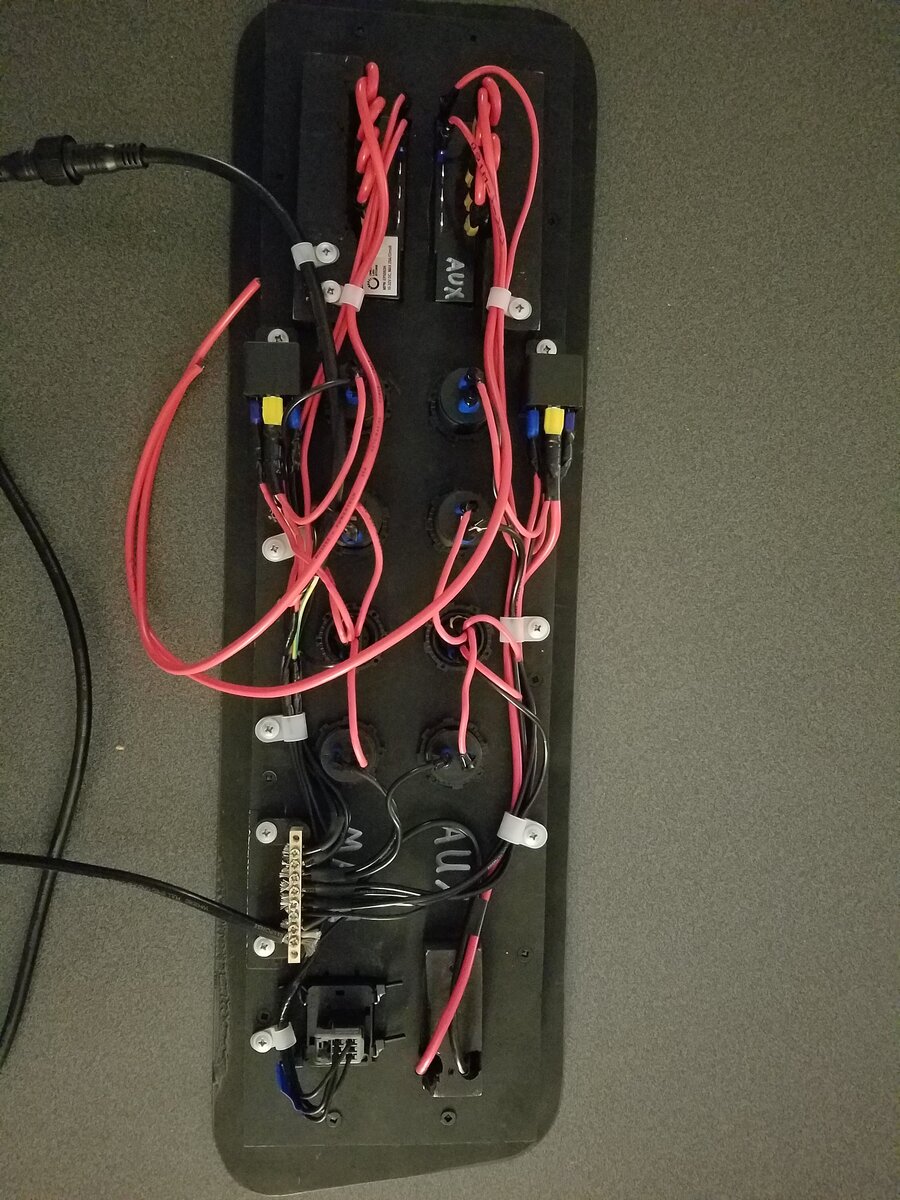

now the fun stuff. i will not dig into the details as everyone's needs will be different but keep it tidy, oversize your wire a little bit, and tie everything down.

installed in the panel. i painted the back of the panel and the rest of the wood back there with fire resistant paint.

hard wiring the panel into my electronics. the black box with grey sticker on the top left is for my lights/accessories, the black box on the top right is the cb/uhf radio, the red box is the 12v/120v power converter. i have power bus bars attached to the wood; unused sections are covered with heat shrink tube to minimize positive/12v electrified surfaces.

tidy fit.

finished up. the reason the plexiglass has that bottom shape is to allow the wires to come out and to be able to open the panel.

here is the final setup. i had to do some custom work on the hinges. i do not recall how they were configured originally but they are basically a solid post that goes into a hole that i drilled into the wood. the screws through the plastic and hinge are countersunk with locking nuts. you will need to figure out your electrical load as i could not have all of mine go through the one toggle switch so i installed a relay.

the top row is for the second/deep cycle battery.

-50amp anderson connector, 12v LED voltmeter, toggle switch, 12v socket, USB charger, 10 way waterproof fuse box (you can find them on amazon). i drilled out backside of the anderson connector to sink the wire through. i looped a zip tie through the fridge side of my anderson connector to help pull it off easier.

the bottom row is wired to the main starter battery.

-120v power outlet (BC3Z-19N236-A with WPT-285 connector in the back) then same stuff as above. i found the power converter on amazon as well.

i removed my factory sub woofer when i first purchased the truck and installed a custom sub/amp set up in the floor (possible write up one day) so it has been an unused area for years. since moving to Australia, where most 4x4s have fridges in the back, i wanted to install a more permanent solution for providing power to the fridge. behind the panel, i also installed the cb/uhf radio, the 12v/120v power converter, and the switch/power box for my roof lights (write up coming). the power for the set up comes from my main battery and my second battery (3rd Gen Dual Battery Setup). this project took many days to complete but it was fun.

there is a fair amount of room once the sub is removed.

i started by removing the factory grill. just have to pick/cut away at the melted plastic attachment points holding it on.

next, i traced out the factory grill on a piece of 12mm thick mdf. sand down the perimeter to get close to the factory grill design so it comes in flush with the side panel.

test fit the panel.

more test fitting.

you need to create some depth to protect the wires coming out in the front but clearance for the electronics and wires behind. roughly 1 1/8" width trim board with 6mm mdf for the back board.

this is the layout i wanted for my electronics. flush mount the screws so you can fill the holes with wood putty. (i later remade this board to swap the 120v and anderson plug locations as the 120v outlet cover could not be open with the plastic window shut)

back side shot. two takeaways here - i premounted the blocks on the sides first, screwing them in from the front then installing the panel and putting in screws to the sides to hold the panel (the blocks have an angle to fit flush on the wood panel). i also installed blocking on the back to give the fuse panel and anderson connector something to screw into securely.

test fit of the smoked plastic panel. cut and sanded to fit. the opening at the bottom is to allow the wires to come out with the plastic window shut.

lots of glue, screws, wood putty, sanding, paint, fiberglass resin, and more paint. i took the factory grill to the local paint/box store and they matched the color for me after telling me the paint is not designed for car use. :-| after a primer coat, i applied one color coat then coated it twice with fiberglass resin to add some scratch resistance, sanded it and added maybe two more layers of color paint.

now the fun stuff. i will not dig into the details as everyone's needs will be different but keep it tidy, oversize your wire a little bit, and tie everything down.

installed in the panel. i painted the back of the panel and the rest of the wood back there with fire resistant paint.

hard wiring the panel into my electronics. the black box with grey sticker on the top left is for my lights/accessories, the black box on the top right is the cb/uhf radio, the red box is the 12v/120v power converter. i have power bus bars attached to the wood; unused sections are covered with heat shrink tube to minimize positive/12v electrified surfaces.

tidy fit.

finished up. the reason the plexiglass has that bottom shape is to allow the wires to come out and to be able to open the panel.

here is the final setup. i had to do some custom work on the hinges. i do not recall how they were configured originally but they are basically a solid post that goes into a hole that i drilled into the wood. the screws through the plastic and hinge are countersunk with locking nuts. you will need to figure out your electrical load as i could not have all of mine go through the one toggle switch so i installed a relay.

the top row is for the second/deep cycle battery.

-50amp anderson connector, 12v LED voltmeter, toggle switch, 12v socket, USB charger, 10 way waterproof fuse box (you can find them on amazon). i drilled out backside of the anderson connector to sink the wire through. i looped a zip tie through the fridge side of my anderson connector to help pull it off easier.

the bottom row is wired to the main starter battery.

-120v power outlet (BC3Z-19N236-A with WPT-285 connector in the back) then same stuff as above. i found the power converter on amazon as well.