- Joined

- February 8, 2003

- Messages

- 9,824

- Reaction score

- 84

- City, State

- Sacramento, CA 95827

- Year, Model & Trim Level

- 1992 XLT

This is part 3 of a series. Part 1 is here:

http://www.explorerforum.com/forums/showthread.php?t=128800

Part 2 is here:

http://www.explorerforum.com/forums/showthread.php?t=157283

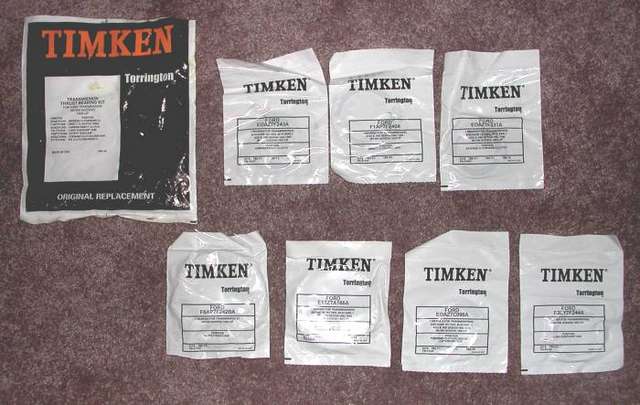

Every transmission has internal tolerances... end to end. These are controlled by what are called "thrust washers" and by actual bearings... known as "torrington bearings". The 4R70W has 7 torringtons... impressive.

In my mind torrington bearings equal longevity and durability.

So here are the torringtons..... as I said... 7 is awesome. Here they are

And the master list:

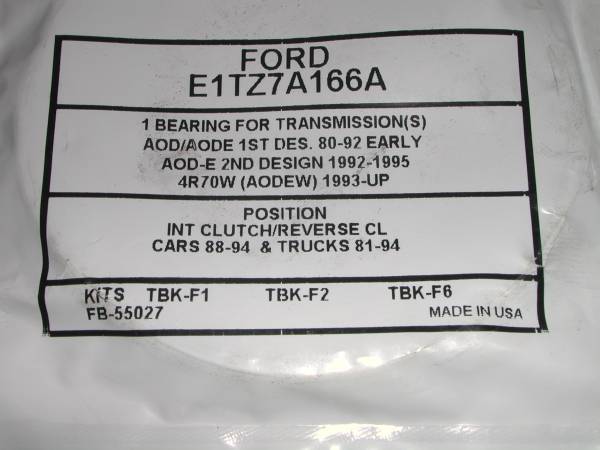

each individual packet has its own description

There are a few "thrust washers", and some plastic (!) "selectives" used to set end play that we will look at as well... and a least one bronze thrust washer... but for now you get the idea. I will also add a sidebar about torringtons.

My advice is, although you may feel like a kid at Christmas when you get your torringtons, DO NOT open them until it is time to use them. Some are seemingly alike.... avoid being confused. Oh, I also dip mine in ATF prior to use as startup lubrication.

http://www.explorerforum.com/forums/showthread.php?t=128800

Part 2 is here:

http://www.explorerforum.com/forums/showthread.php?t=157283

Every transmission has internal tolerances... end to end. These are controlled by what are called "thrust washers" and by actual bearings... known as "torrington bearings". The 4R70W has 7 torringtons... impressive.

In my mind torrington bearings equal longevity and durability.

So here are the torringtons..... as I said... 7 is awesome. Here they are

And the master list:

each individual packet has its own description

There are a few "thrust washers", and some plastic (!) "selectives" used to set end play that we will look at as well... and a least one bronze thrust washer... but for now you get the idea. I will also add a sidebar about torringtons.

My advice is, although you may feel like a kid at Christmas when you get your torringtons, DO NOT open them until it is time to use them. Some are seemingly alike.... avoid being confused. Oh, I also dip mine in ATF prior to use as startup lubrication.