kjtooltime

New Member

- Joined

- September 29, 2010

- Messages

- 4

- Reaction score

- 0

- City, State

- Oceanside, Ca

- Year, Model & Trim Level

- 1996 XLT 5.0L

Hi All,

I have a 1996 Explorer with a V8 and 4 wheel disk that has an ABS light that stays on all the time (with Key on only or if the engine is running and vehicle moving).

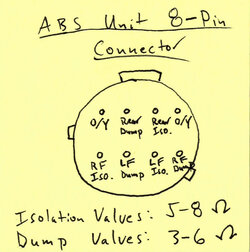

Using a scan tool, I was able to pull ABS Code C1194 (ABS outlet valve coil LF Circuit Failure). From the research that I did, it seemed to point to the ABS Module. I replaced the module (located in the left fender next to the battery) and the light is still on.

I have also checked the continuity of all the sensors.

What else could be the problem?

Does a new ABS module have to be programmed?

Any help would be greatly appreciated.

Thanks!

I have a 1996 Explorer with a V8 and 4 wheel disk that has an ABS light that stays on all the time (with Key on only or if the engine is running and vehicle moving).

Using a scan tool, I was able to pull ABS Code C1194 (ABS outlet valve coil LF Circuit Failure). From the research that I did, it seemed to point to the ABS Module. I replaced the module (located in the left fender next to the battery) and the light is still on.

I have also checked the continuity of all the sensors.

What else could be the problem?

Does a new ABS module have to be programmed?

Any help would be greatly appreciated.

Thanks!