- Joined

- February 8, 2003

- Messages

- 9,824

- Reaction score

- 84

- City, State

- Sacramento, CA 95827

- Year, Model & Trim Level

- 1992 XLT

HIGH REVERSE CLUTCH

This one is pretty straightforward. Prior to disassembly, I checked the clearance on the clutch pack... it was .070, which is within normal tolerance. ( I want something tighter on rebuild)

Next step is to remove the snap ring... easy enough...

Then the pressure plate

followed by the stack of frictions and steels. Now we are left with the spring retainer, held in place by a snap ring... this will need the spring compressor.

Here's mine.... I picked it up off E-Bay for about $75, if you do a Google Search for Transmission Spring Compressors you will find the KD model (which this is am sure, even though it came in a Snap On case) for about that price. I have some issues with the design, and you can even make a DIY version, but for now, this one works.... so... here it is

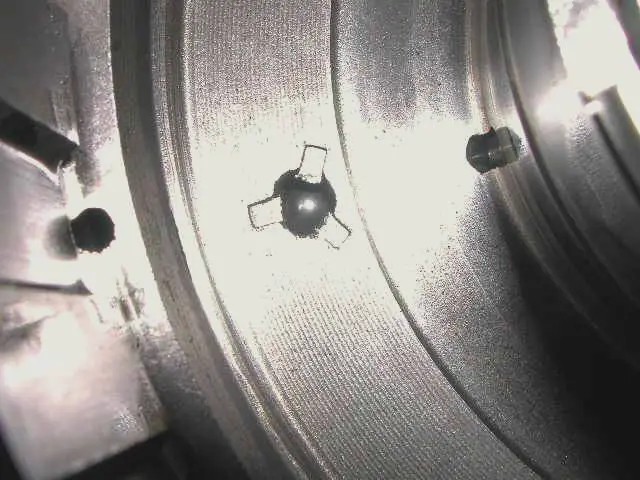

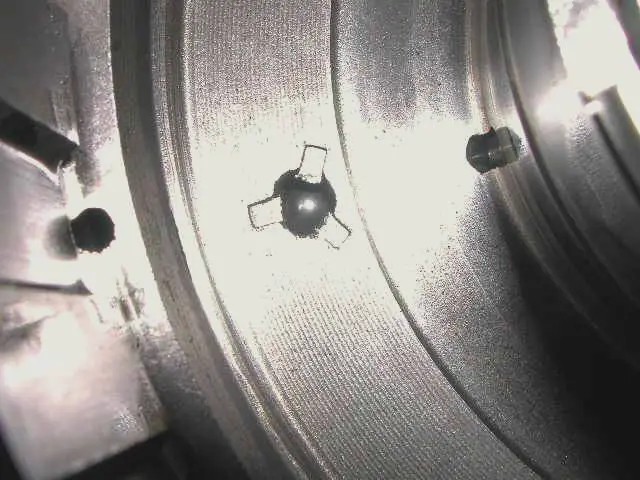

The one you see in the books is made by Owatonna Tool, do a web search for OTC-7024 and you will find it. It seems to go for about $100. Anyway, about mine...It is designd to snag in the snap ring groove, once the ring is out and the plates removed. You install it by squeezing the legs close together and letting it grab in the snap ring groove. Here it is installed

One of my complaints is that this design eats up valuable working room inside the drum. Anyway rotate the knob, compress the springs, and remove the snap ring, as best you can, in the space you have....

With it out you have just the retainer sitting there, begging to come out...

And underneath SPRINGS !

20 of 'em to be exact. Yep, another HANDFULL !! (could not resist). These are replaced with NEW ones from a kit.

In this one all it took was a smart upside down RAP and the piston fell out...

This one has lip seals.. which I just noticed from the pictures appear to have been installed backwards! (hard to tell though)

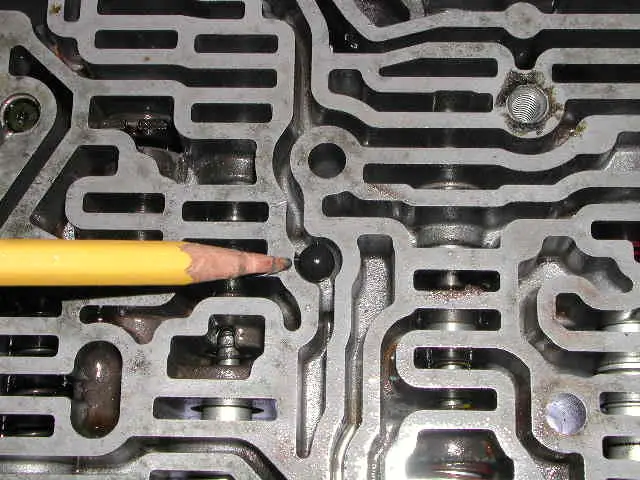

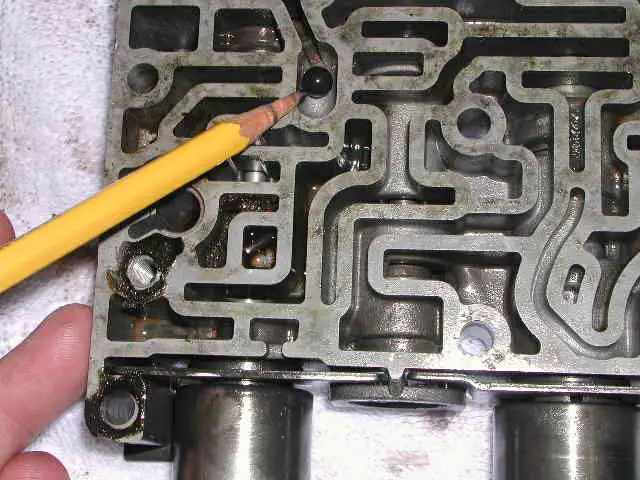

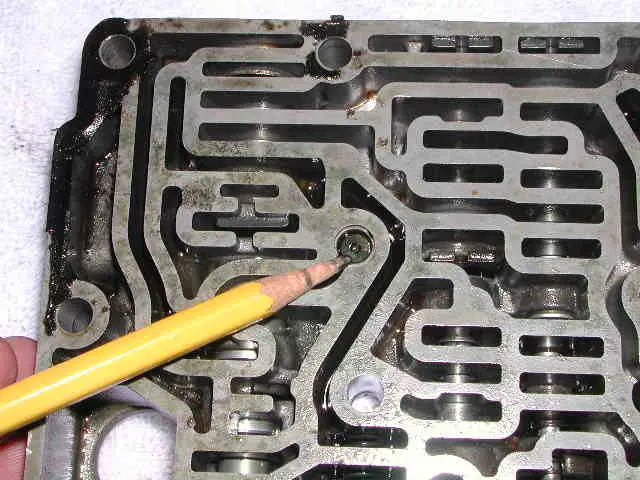

There is another check valve thingie, blow it out from BOTH sides... this one, like the other, did not rattle until cleaned, now it rattles !

Easiest way to get the old seals out ?

Snag that baby and pull 'er out..

(looking close here, I am still wondering if these were in upside down). Anyway pull it out.

And with that the High/Reverse drum is all apart! Take a break and have a cold one.

This one is pretty straightforward. Prior to disassembly, I checked the clearance on the clutch pack... it was .070, which is within normal tolerance. ( I want something tighter on rebuild)

Next step is to remove the snap ring... easy enough...

Then the pressure plate

followed by the stack of frictions and steels. Now we are left with the spring retainer, held in place by a snap ring... this will need the spring compressor.

Here's mine.... I picked it up off E-Bay for about $75, if you do a Google Search for Transmission Spring Compressors you will find the KD model (which this is am sure, even though it came in a Snap On case) for about that price. I have some issues with the design, and you can even make a DIY version, but for now, this one works.... so... here it is

The one you see in the books is made by Owatonna Tool, do a web search for OTC-7024 and you will find it. It seems to go for about $100. Anyway, about mine...It is designd to snag in the snap ring groove, once the ring is out and the plates removed. You install it by squeezing the legs close together and letting it grab in the snap ring groove. Here it is installed

One of my complaints is that this design eats up valuable working room inside the drum. Anyway rotate the knob, compress the springs, and remove the snap ring, as best you can, in the space you have....

With it out you have just the retainer sitting there, begging to come out...

And underneath SPRINGS !

20 of 'em to be exact. Yep, another HANDFULL !! (could not resist). These are replaced with NEW ones from a kit.

In this one all it took was a smart upside down RAP and the piston fell out...

This one has lip seals.. which I just noticed from the pictures appear to have been installed backwards! (hard to tell though)

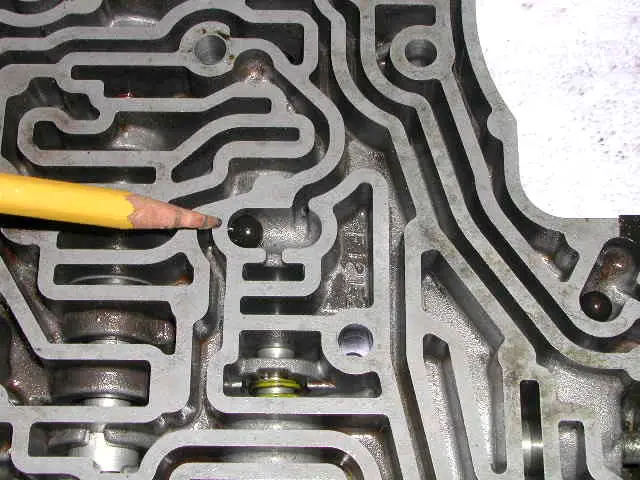

There is another check valve thingie, blow it out from BOTH sides... this one, like the other, did not rattle until cleaned, now it rattles !

Easiest way to get the old seals out ?

Snag that baby and pull 'er out..

(looking close here, I am still wondering if these were in upside down). Anyway pull it out.

And with that the High/Reverse drum is all apart! Take a break and have a cold one.

Can I send you my 5R55E for rebuilding once you get done with this project?

Can I send you my 5R55E for rebuilding once you get done with this project?