Final aspect of teardown

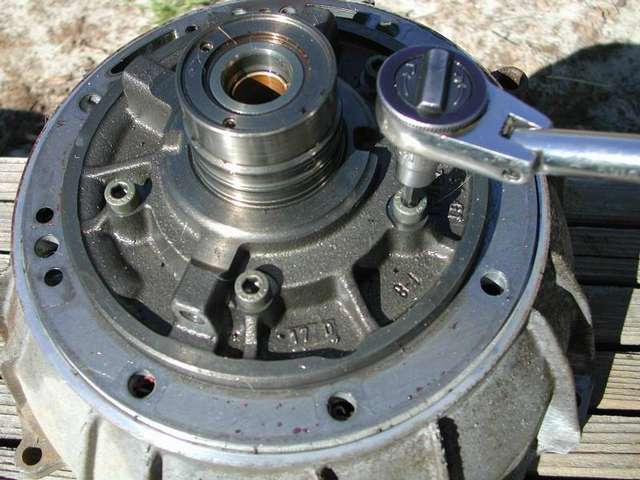

Well, as I write this I am already starting into th rebuild, but the onething we didn;t do in this teardwn part of this thread is tear down the pump/bellhousing. No a lot to it. Remove the pump allen head bolts (6mm)

Here's the pump gearset and the pump body once removed

Here's the pump separator plate coming off with the pump removed

And the end of the bellhousing underneath

This was a rebuild... I'll show you in a bit how I know.... but the pump shaft showed ascarsof eccentric rotation (eg lack of beng centered)... I'll post a couple pics hoping to show it... here's the first, see the wear ?

heres the 2nd

And here is the infamous bushing - this one has had some wars... scarred

ok, I had been told this was rebuilt. But I KNEW it was once I had lookd in the bellhousing.

Like rings on a tree, the number of "stake marks" (4 per build) give it away. This seal shows 10 ...equals at least one rebuild.

We will be exchanging the bellhousing for one with a line bored bushing and a new seal.... so with this, the teardown is complete. On the rebuild I will try and show how to DIY parts of the seal and bushing replacement... BUT ....the only right way is to get it line bored.. on this point I AM resolute. Disgree if you like, but GET IT LINE BORED! Or be sorry.