- Joined

- February 8, 2003

- Messages

- 9,824

- Reaction score

- 84

- City, State

- Sacramento, CA 95827

- Year, Model & Trim Level

- 1992 XLT

Well I'm back. When I did the A4LD rebuild diary I rather shorted the Valve body rebuild portion. Tn Explorer did a great writeup and kind of filled in the void there, but I wanted to add one of my own. In this thread I will compare valve body rebuild kits (sometimes referred to as shift kits, or correction kits), show where they overlap, recommend upgrades and try and show you how to rebuild yours. My goal (we'll see if THIS happens) is to show each bore, explain the function of that bore's contents, and maybe pass along a few tricks that you can use to get a little extra life out of your own A4LD.

[For those of you with 95 and up Explorers, I did a similar thread on rebuilding the 5R55E Valve body, here's a link to that thread] http://www.explorerforum.com/forums/showthread.php?t=140987

So.... let's start by talking about shift, or as is more accurate in this csase, correction kits. As we speak I am only aware of two main ones (If I am wrong someone please correct me) they are kits made by TRANSGO and by SUPERIOR. They are quite different and yet they do cross over.

For newbies, let's briefly talk about shift kits. In the case of some transmissions shift kits can dramatically alter how your transmission operates. You can go from mild to wild. In the case of our humble A4LD, not quite to exhorbitant, yet you can make decisions about shifting. Shift kits, in a general sense, are aftermarket attempts to correct what they see as "failings" in the original design of a valve body. Let's back up, a valve body (sometimes called a control unit) is the "brains" of your transmission. A hydraulic miracle, valves, springs, passageways, etc etc. But they work, and you CAN teach an old dog new tricks!

Here are the two kits...

Superior is on the left, TRANSGO in the right. Cost? I paid $22.03 for the TRANSGO and $46.99 for the Superior.

Let's see what each has in it. Starting with the more expensive Superior.

When you open the box here is what you get.... Instructions (both are VERY GOOD) and a plastic bag of "stuff"

In that bag on the left are springs for a clutch... not something you will use for a simple valve body project. They require a teardown to install. On the right is the main "guts" of what you will use.... springs and a drill bit. This next pic shows you an idea of how clear and good the instructions are:

As for the bag of springs etc, here they are all arranged

If you ignore the drill bit, and start at the one o'clock position, in the greenish pouch you have a throttle valve replacement (located under the modulator on the side of the transmission) The next "white" one is a replacement spring for the convertor clutch shuttle valve (under the TCC solenoid - more later). The whispy spring is a "return" spring for the governor... a great IDEA...lacking in the original design of the A4LD... The blue spring and the one across from it (brown) are governor replacement springs for Aerostar and Explorer.... one or the other. The drill bit is to drill out the accumulator pucks if you so desire....and the valve body...the big pink spring is for the intermediate servo (not a valve body project), and the one next to it is for the "boost valve". The bag of springs is, as I have said, for a clutch pack.

Ok now the TRANSGO

In the pouches you have at the top, new rings for the center support (tear down to install) and a replacement srping for the low reverse servo (doable as part of a VB rebuild). The other 2 are VB springs and a couple of drill bits. TRANSGO gives you instructions on drilling the separator plate (brain surgery for how your trannie will operate) and gives you the bits for that, with EXCELLENT instructions (we'll cover that in more detail later). Here are come of the "bags" of contents. Here we have the orange spring (convertor clutch valve) and the green one (torque convertor shuttle valve) as well as one whose purpose escapes me at the moment. Plus the washer for the TCC solenoid.

The next one is easy.. the sealing rings for the center support and the replacement spring for the low reverse servo.

finally...the main parts...

on the left are boost valve springs, inner and outer (Superior only had the bigger outer), next to them is the blue outer (color not showing, that goes with the one 2 to the right as the inner on the early model 2-3 backout valve (relax we will talk about each of these as we get to them and their functions). In between is the return spring on the cutback valve. Lastly the two white ones are inner and outer for the later style (Explorer) 2-3 backout.

The Transgo has a great exploded view of all the valve body parts, even better than the FORD factory manual

We also are going to add the Sonnax Boost valve upgrade (left) and the manual valve indexer (right)

An important upgrade in my opinion is the boost valve with O-rings. Here is the old valve and springs (it looks like maybe this VB had a shift kit in it, not sure) and above it the Superior kit spring, the Transgo spring(s) and below the new valve assembly....

Tomorrow we will start putting all this in place.

[For those of you with 95 and up Explorers, I did a similar thread on rebuilding the 5R55E Valve body, here's a link to that thread] http://www.explorerforum.com/forums/showthread.php?t=140987

So.... let's start by talking about shift, or as is more accurate in this csase, correction kits. As we speak I am only aware of two main ones (If I am wrong someone please correct me) they are kits made by TRANSGO and by SUPERIOR. They are quite different and yet they do cross over.

For newbies, let's briefly talk about shift kits. In the case of some transmissions shift kits can dramatically alter how your transmission operates. You can go from mild to wild. In the case of our humble A4LD, not quite to exhorbitant, yet you can make decisions about shifting. Shift kits, in a general sense, are aftermarket attempts to correct what they see as "failings" in the original design of a valve body. Let's back up, a valve body (sometimes called a control unit) is the "brains" of your transmission. A hydraulic miracle, valves, springs, passageways, etc etc. But they work, and you CAN teach an old dog new tricks!

Here are the two kits...

Superior is on the left, TRANSGO in the right. Cost? I paid $22.03 for the TRANSGO and $46.99 for the Superior.

Let's see what each has in it. Starting with the more expensive Superior.

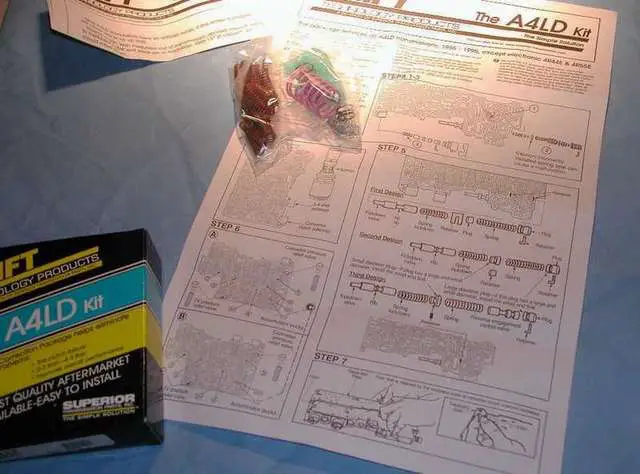

When you open the box here is what you get.... Instructions (both are VERY GOOD) and a plastic bag of "stuff"

In that bag on the left are springs for a clutch... not something you will use for a simple valve body project. They require a teardown to install. On the right is the main "guts" of what you will use.... springs and a drill bit. This next pic shows you an idea of how clear and good the instructions are:

As for the bag of springs etc, here they are all arranged

If you ignore the drill bit, and start at the one o'clock position, in the greenish pouch you have a throttle valve replacement (located under the modulator on the side of the transmission) The next "white" one is a replacement spring for the convertor clutch shuttle valve (under the TCC solenoid - more later). The whispy spring is a "return" spring for the governor... a great IDEA...lacking in the original design of the A4LD... The blue spring and the one across from it (brown) are governor replacement springs for Aerostar and Explorer.... one or the other. The drill bit is to drill out the accumulator pucks if you so desire....and the valve body...the big pink spring is for the intermediate servo (not a valve body project), and the one next to it is for the "boost valve". The bag of springs is, as I have said, for a clutch pack.

Ok now the TRANSGO

In the pouches you have at the top, new rings for the center support (tear down to install) and a replacement srping for the low reverse servo (doable as part of a VB rebuild). The other 2 are VB springs and a couple of drill bits. TRANSGO gives you instructions on drilling the separator plate (brain surgery for how your trannie will operate) and gives you the bits for that, with EXCELLENT instructions (we'll cover that in more detail later). Here are come of the "bags" of contents. Here we have the orange spring (convertor clutch valve) and the green one (torque convertor shuttle valve) as well as one whose purpose escapes me at the moment. Plus the washer for the TCC solenoid.

The next one is easy.. the sealing rings for the center support and the replacement spring for the low reverse servo.

finally...the main parts...

on the left are boost valve springs, inner and outer (Superior only had the bigger outer), next to them is the blue outer (color not showing, that goes with the one 2 to the right as the inner on the early model 2-3 backout valve (relax we will talk about each of these as we get to them and their functions). In between is the return spring on the cutback valve. Lastly the two white ones are inner and outer for the later style (Explorer) 2-3 backout.

The Transgo has a great exploded view of all the valve body parts, even better than the FORD factory manual

We also are going to add the Sonnax Boost valve upgrade (left) and the manual valve indexer (right)

An important upgrade in my opinion is the boost valve with O-rings. Here is the old valve and springs (it looks like maybe this VB had a shift kit in it, not sure) and above it the Superior kit spring, the Transgo spring(s) and below the new valve assembly....

Tomorrow we will start putting all this in place.