SteveRosenow

Active Member

- Joined

- June 25, 2019

- Messages

- 64

- Reaction score

- 7

- City, State

- Shelton, Washington

- Year, Model & Trim Level

- 1996 Ford Explorer XLT

Sooooo..

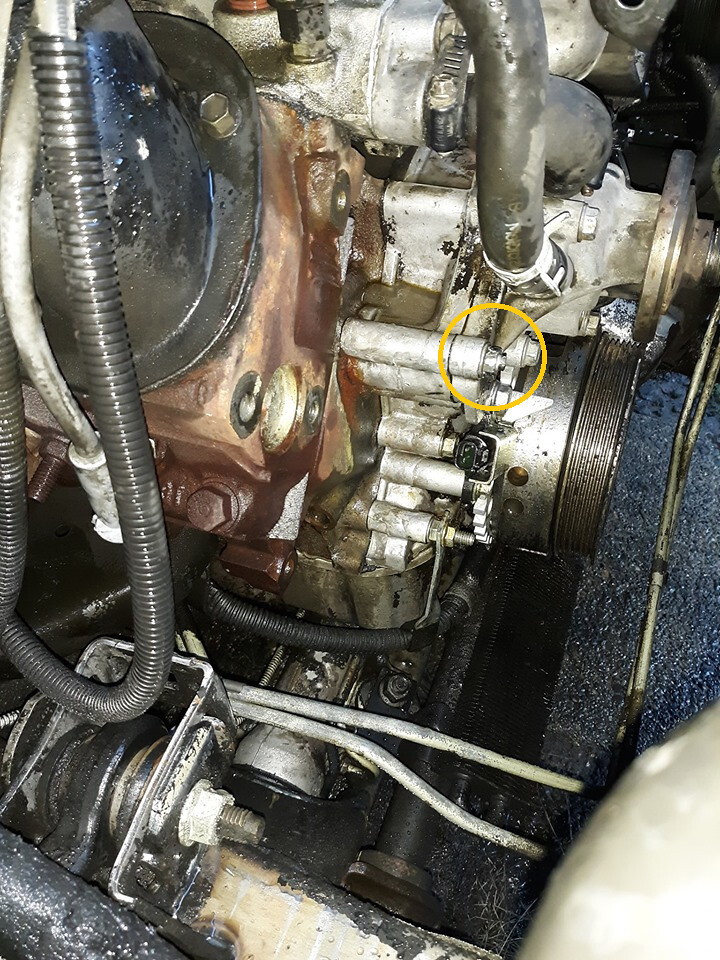

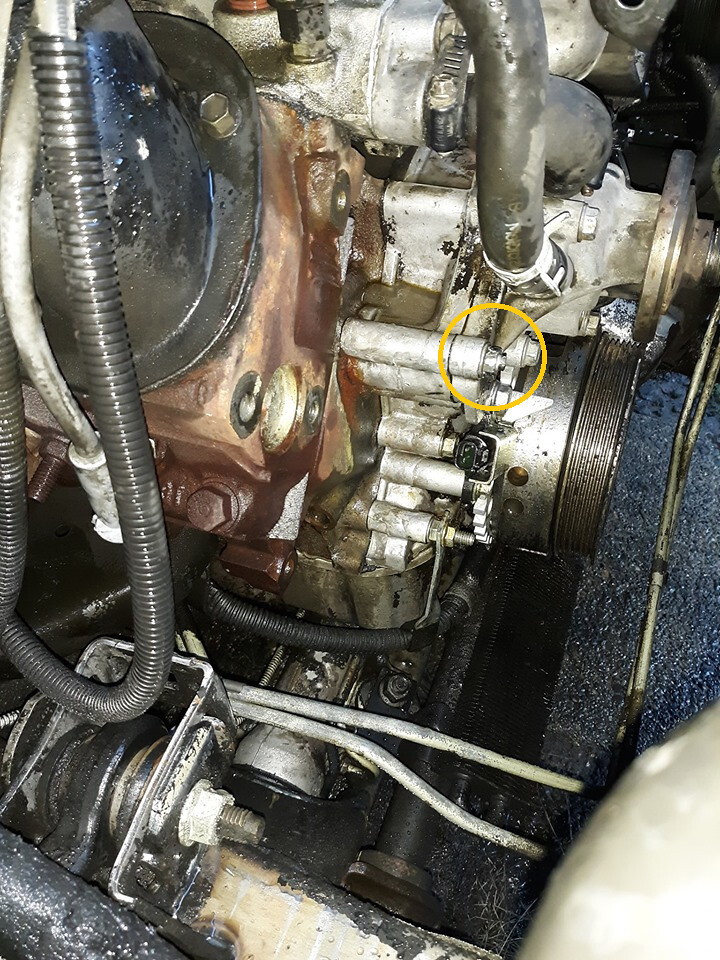

I am at my wits end and feeling defeated. I took some time off and away from the water pump replacement to gather some tools and the right hardware to do the job... The two bolts I am having problems with are the ones highlighted by the two yellow circles:

Here's the tools I decided to get, just in case I needed to get frisky...

1.) MAP gas torch to heat the bolts

2.) Stud removal tool. I bought the one at O'Reilly Auto (since I work there).

3.) Stripped bolt extractor sockets... These guys:

4.) Breaker bar extension

5.) Angle grinder with cutting wheel.

Sooo, tonight after I bought the last tool set I needed, I decided to get down and dirty with the water pump replacement attempt. The second try saw the studs which hold the two wire harness clips be sheared off via the stud extractor a week ago.

Tonight, things were much, much worse. The stud extractor managed to shear off the stud holding the pin for the wire harness clip on the right side of the water pump. This allowed me some wiggle room to try my hand at working the bolt extractor... Before I went in, I heated the bolt to nearly glowing, then waited for things to cool for a bit before getting in there... And that's where things took a turn for the worst.

Trying the breaker bar and the 13mm bolt extractor was an exercise in futility. Not only did the bolt head itself strip out into a rounded head, the bolt extractor itself rounded out! So now, I have a useless bolt extractor and a bolt head that just will not come out.

I've attached a photo of the left hand bolt below. The right hand bolt is a little better but will not budge!

I purchased a corded angle grinder to get in there thinking I'd have a bit of room. Sadly, I don't.

I don't want to remove the power steering pump and A/C compressor because I don't want to have ATF all over the engine nor do I have the means of evacuating the A/C system and recharging it.

What do I do? Drive around with Bars Leaks Liquid Aluminum for two weeks while I wait to have it taken to a shop?

I have the timing cover and water pump already and it is irritating me to no end.

I am at my wits end and feeling defeated. I took some time off and away from the water pump replacement to gather some tools and the right hardware to do the job... The two bolts I am having problems with are the ones highlighted by the two yellow circles:

Here's the tools I decided to get, just in case I needed to get frisky...

1.) MAP gas torch to heat the bolts

2.) Stud removal tool. I bought the one at O'Reilly Auto (since I work there).

3.) Stripped bolt extractor sockets... These guys:

4.) Breaker bar extension

5.) Angle grinder with cutting wheel.

Sooo, tonight after I bought the last tool set I needed, I decided to get down and dirty with the water pump replacement attempt. The second try saw the studs which hold the two wire harness clips be sheared off via the stud extractor a week ago.

Tonight, things were much, much worse. The stud extractor managed to shear off the stud holding the pin for the wire harness clip on the right side of the water pump. This allowed me some wiggle room to try my hand at working the bolt extractor... Before I went in, I heated the bolt to nearly glowing, then waited for things to cool for a bit before getting in there... And that's where things took a turn for the worst.

Trying the breaker bar and the 13mm bolt extractor was an exercise in futility. Not only did the bolt head itself strip out into a rounded head, the bolt extractor itself rounded out! So now, I have a useless bolt extractor and a bolt head that just will not come out.

I've attached a photo of the left hand bolt below. The right hand bolt is a little better but will not budge!

I purchased a corded angle grinder to get in there thinking I'd have a bit of room. Sadly, I don't.

I don't want to remove the power steering pump and A/C compressor because I don't want to have ATF all over the engine nor do I have the means of evacuating the A/C system and recharging it.

What do I do? Drive around with Bars Leaks Liquid Aluminum for two weeks while I wait to have it taken to a shop?

I have the timing cover and water pump already and it is irritating me to no end.