2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,597

- Reaction score

- 334

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

Dyno data files

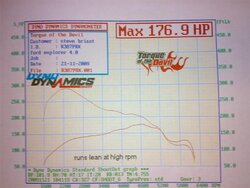

The scan below is of my stock SOHC pulling in 4th gear which is speed limited at 105 mph.

The scan below is of my stock SOHC pulling in 2nd gear to obtain a wider rpm range and avoid downshifting.

The scan below is for 2nd gear pull with a mod to eliminate slack in the throttle cable.

The scan below is for 2nd gear pull with the throttle cable mod and an Akimoto Racing high flow air filter.

this is a great thread, im also on similier line of tuning mine up, would you happen to have the dyno print outs so i could compare with mine? ill post them up here when i get the photo copier working.

The scan below is of my stock SOHC pulling in 4th gear which is speed limited at 105 mph.

The scan below is of my stock SOHC pulling in 2nd gear to obtain a wider rpm range and avoid downshifting.

The scan below is for 2nd gear pull with a mod to eliminate slack in the throttle cable.

The scan below is for 2nd gear pull with the throttle cable mod and an Akimoto Racing high flow air filter.