EB4X

Explorer Addict

- Joined

- December 28, 2016

- Messages

- 1,370

- Reaction score

- 915

- City, State

- Orange county, Ca

- Year, Model & Trim Level

- 95 Explorer 4X 4.0 ohv

Hey gang,

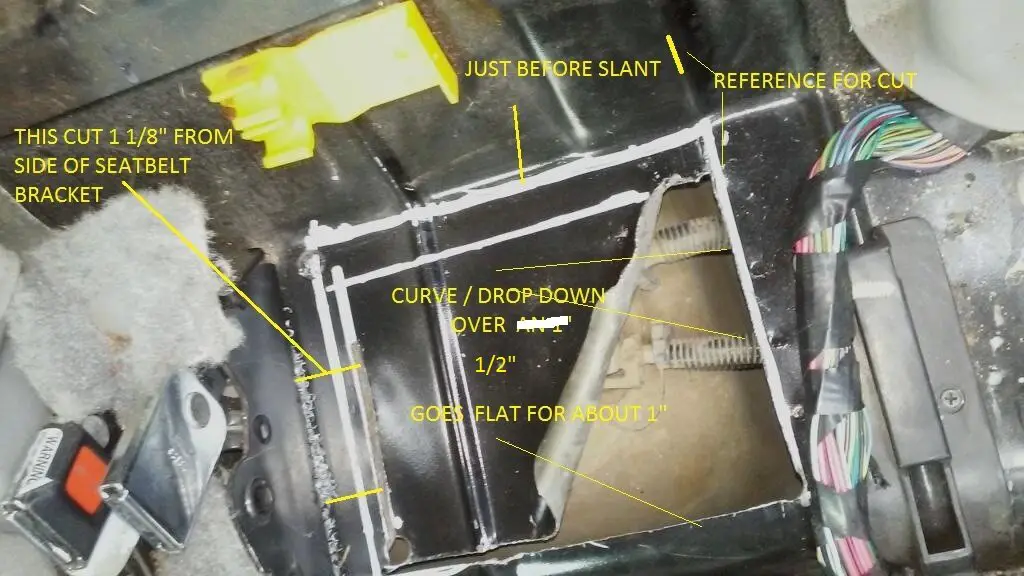

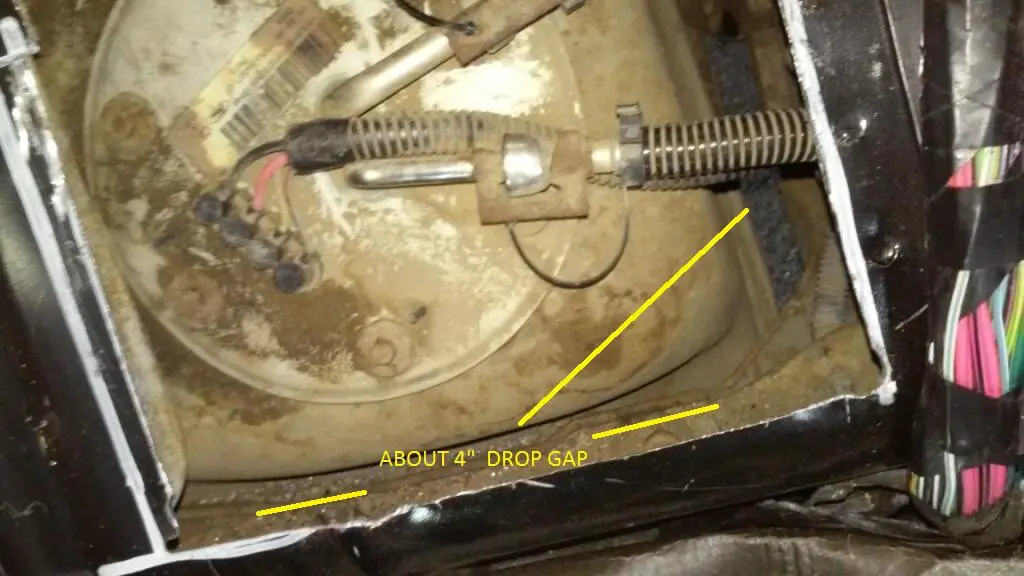

Thought I'd post this for anyone interested....I'm not sure if the 97 is in same spot (most likely since same back hatch/ setup) but sure 98 and up are a few inches further back and to the left a hair --and more troublesome due to metal contour. (The part numbers for a 95 versus a 96 gas tank are DIFFERENT...but pump falls EXACTLY at some spot ...as expected.)

Anyway, here's some pics...couple with notes...

Will probably post after pics of custom cover panel once pump arrives --might clean up / file back cut too. The back area/ cut before upward slant becomes a double layer hence semi sloppy cut --- my cheapo metal nibbler couldn't handle double layer -- would recommend using beefier/thicker cut range if had to do again --though this cheapo one worked like a champ for 80% of job.... didn't go over small rib though either. (Only $11.49 on Ebay - free ship) Had to cut Sawzall / reciprocating saw blade down to about a 1 1/2" length (for safety) to tackle challenging spots. (Stupid blades wouldn't stay in jig saw...otherwise that would've been great option)

Thought I'd post this for anyone interested....I'm not sure if the 97 is in same spot (most likely since same back hatch/ setup) but sure 98 and up are a few inches further back and to the left a hair --and more troublesome due to metal contour. (The part numbers for a 95 versus a 96 gas tank are DIFFERENT...but pump falls EXACTLY at some spot ...as expected.)

Anyway, here's some pics...couple with notes...

Will probably post after pics of custom cover panel once pump arrives --might clean up / file back cut too. The back area/ cut before upward slant becomes a double layer hence semi sloppy cut --- my cheapo metal nibbler couldn't handle double layer -- would recommend using beefier/thicker cut range if had to do again --though this cheapo one worked like a champ for 80% of job.... didn't go over small rib though either. (Only $11.49 on Ebay - free ship) Had to cut Sawzall / reciprocating saw blade down to about a 1 1/2" length (for safety) to tackle challenging spots. (Stupid blades wouldn't stay in jig saw...otherwise that would've been great option)