- Joined

- November 11, 2005

- Messages

- 56,687

- Reaction score

- 1,186

- City, State

- Brooklyn, NY

- Year, Model & Trim Level

- 88 89 93 95 96 Aerostars

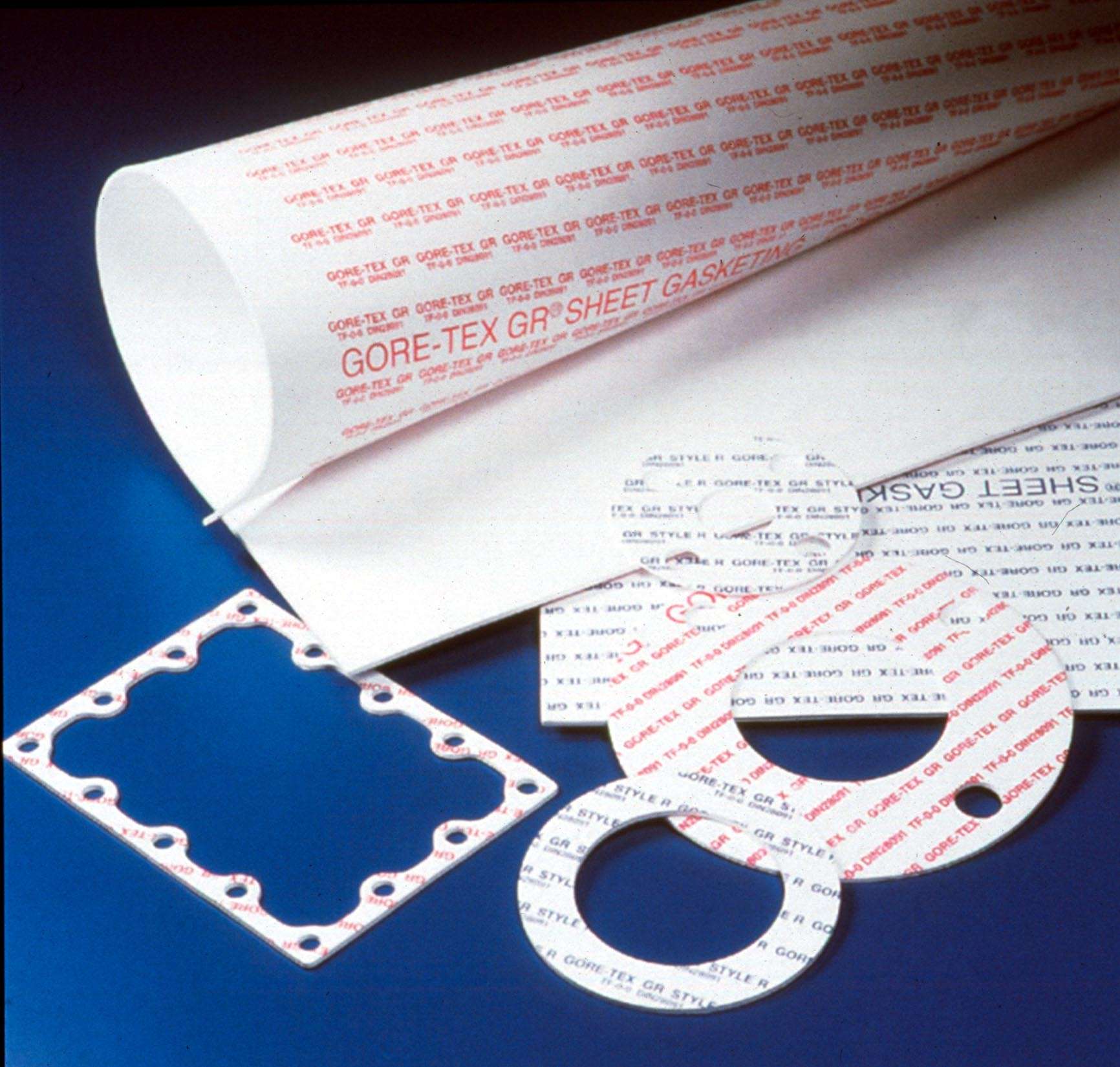

Many times it's necessary to either buy a gasket or reuse an old one when a new one isn't available (if it's a reusable design). Sometimes the replacement gaskets aren't good quality, and fail after a short time. This might be the case with certain paper gaskets that are very thin. Paper becomes brittle after a while when it ages or comes into constant contact with heat, and moisture. This is the case with water pump gaskets or thermostat housing gaskets. Plumbing stores, and industrial supply houses sell high temperature gasket material by the sheet such as this roll in the picture below:

This thread will show you one way of making your own high quality gaskets when one isn't available or if you just want to have a reliable, leak proof gasket. There are many ways of doing this such as using a router, drill press or other methods, but we will keep it simple for people that don't have access to elaborate tools.

This 15 piece gasket punch set was purchased from Harbor Freight in 2000 for $15:

There are other manufacturers of gasket punch sets if this one isn't available. The next thing that you will need is a hobby knife set to trim all of the curves that an ordinary scissor will have difficulty doing. This one was purchased in a dollar store:

The piece in the background is a high quality cutting board that was the biggest one that I was able to find on Amazon. It was $20. An ordinary piece of wood will work if you don't have a cutting board, but the cutting board is much more durable, and will last a lot longer.

To get started, I have an A4LD transmission air test plate that needs a gasket. The test plate is placed onto the gasket material, and is marked with a pen. The other edges are traced as well as the holes. The holes are two different sizes on this test plate.

You could see the trace marks on the gasket from the air test plate:

This is a close up view:

The hobby knife is cutting the sides of the gasket to get all of the crevices that a basic cutting tool can't reach:

This thread will show you one way of making your own high quality gaskets when one isn't available or if you just want to have a reliable, leak proof gasket. There are many ways of doing this such as using a router, drill press or other methods, but we will keep it simple for people that don't have access to elaborate tools.

This 15 piece gasket punch set was purchased from Harbor Freight in 2000 for $15:

There are other manufacturers of gasket punch sets if this one isn't available. The next thing that you will need is a hobby knife set to trim all of the curves that an ordinary scissor will have difficulty doing. This one was purchased in a dollar store:

The piece in the background is a high quality cutting board that was the biggest one that I was able to find on Amazon. It was $20. An ordinary piece of wood will work if you don't have a cutting board, but the cutting board is much more durable, and will last a lot longer.

To get started, I have an A4LD transmission air test plate that needs a gasket. The test plate is placed onto the gasket material, and is marked with a pen. The other edges are traced as well as the holes. The holes are two different sizes on this test plate.

You could see the trace marks on the gasket from the air test plate:

This is a close up view:

The hobby knife is cutting the sides of the gasket to get all of the crevices that a basic cutting tool can't reach: