I got tired of the computer deciding when my 5R55E transmission should shift, since it hadn't a clue with all the mods I've done so I decided It was time for a change. The two choices were a manual, or a 700R4 for a lower crawl ratio. I love having an auto in LA traffic (and Its grown on me wheeling) so I figured I'd be the first to put a 700R4 in a 2nd gen.

All my pics are here, and I'll link the important ones to the thread.

I grabbed the two Advance Adapters parts (4.0 to 700R4, 700R4 to t-case) back in Feb for a great deal, and waited for some more cash to come around to buy the 700R4. I got the 700R4 (Level II) from Bowtie Overdrives, along with their TV system, 1800 rpm stall torque converter, dip stick, and install kit.

The trans arrives:

A few weeks before I put the trans in i decided to install the TV linkage. Somewhere between '91-'94 and 2000 the throttle body linkage changed size, so I got to modify it to fit Bowtie's TV setup. I figured since was modifying anyway I mine as well upgrade and so I threw in a BBK TB.

You can see where i ground the linkage down:

On another weekend I hacked up my center console and installed the B&M Hammer shifter. It sat a little low sitting on the floor, so I welded up a sub-frame for it out of 1" sq. tube. I plan to glass the cover in with the center console so it looks factory. (anyone want to show me how to glass?)

Part way installed:

The next step was to throw in the transmission in a weekend and hope everything else went smoothly since this is still my daily driver.

Friday night (5 hrs):

The first job was to get the control arms from the SFA out of the way, along with its bracketry:

Next, getting ready to take the t-case and transmission out:

Saturday (15 hrs):

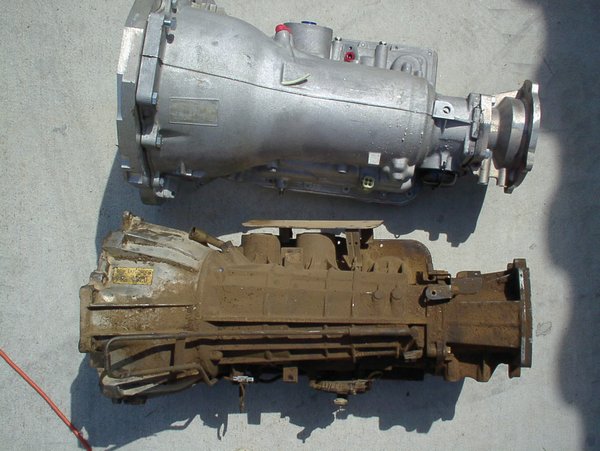

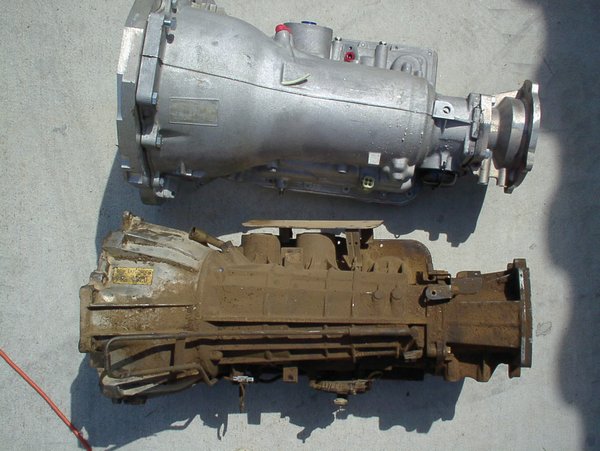

With help, and a very tall floor jack (or a bunch of bricks ) remove t-case and transmission. Compare transmisions (AA tailshaft housing was installed previously, and the 700R4 was built with the AA output shaft):

) remove t-case and transmission. Compare transmisions (AA tailshaft housing was installed previously, and the 700R4 was built with the AA output shaft):

Bolt AA adapter to engine:

Bolt adapter to torque converter and install:

I had to grind down the three bolts in order to get them flush w/ the adapter. Not sure if AA dropped the ball or what.

Bolt up trans:

Bolt up t-case:

Connect TV linkage:

Reroute cooler lines. I used rubber for now. I plan to replace with either braided stainless or hard lines. I had ordered the Bowtie overdrives lines, but they aren't long enough to reach the drivers side tank of the stock radiator, nor are they the right fittings for the radiator.

Sunday (10 hrs):

Wire up shifter. I brought the wires that went to the shift position switch on the 5R through the same hole as the shift cable. By rewraping the wire harness correctly, i didn't have to extend any wires, which was nice.

Wire up torque converter harness. I got bowties harness w/ manual lockup switch, and replaced my shifter handle with one that has a switch. so now I can lock the converter up when i'm climbing in 3rd gear. It works great.

Connect shifter, fill trans and start engine w/o exhaust Y-pipe to get neighbors attention

Modify exhaust. I had to crush the pre-cat on the passenger side in order to get the Y-pipe to fit. The O2 sensor on that side is fine. The O2 sensor on the other side clears the adapter plate by a 1/32", so others may need to grind the adapter to get it to fit. I figured I'd then drive it to an exhaust shop and have them remake my Y-pipe to fit better. However I found out that for such a new vehicle the O2 sensors and pre-cats have to be exact stock distances down the pipe to follow guidlines so no one wanted to help me there. I even talked with the local guy for a good 30 mins coming up with crazy ideas to get it to work, like remoting the oil filter and taking the exhaust around the outside of the frame rail. I ended up just using the tube that AA suplies to extend the Y-pipe so that the cats would bolt up sqaure and clear the trans. I may get to have fun when I need to smog this thing

exhaust pics:

I know I've left out many details, so if anyone has any questions, ask away.

All my pics are here, and I'll link the important ones to the thread.

I grabbed the two Advance Adapters parts (4.0 to 700R4, 700R4 to t-case) back in Feb for a great deal, and waited for some more cash to come around to buy the 700R4. I got the 700R4 (Level II) from Bowtie Overdrives, along with their TV system, 1800 rpm stall torque converter, dip stick, and install kit.

The trans arrives:

A few weeks before I put the trans in i decided to install the TV linkage. Somewhere between '91-'94 and 2000 the throttle body linkage changed size, so I got to modify it to fit Bowtie's TV setup. I figured since was modifying anyway I mine as well upgrade and so I threw in a BBK TB.

You can see where i ground the linkage down:

On another weekend I hacked up my center console and installed the B&M Hammer shifter. It sat a little low sitting on the floor, so I welded up a sub-frame for it out of 1" sq. tube. I plan to glass the cover in with the center console so it looks factory. (anyone want to show me how to glass?)

Part way installed:

The next step was to throw in the transmission in a weekend and hope everything else went smoothly since this is still my daily driver.

Friday night (5 hrs):

The first job was to get the control arms from the SFA out of the way, along with its bracketry:

Next, getting ready to take the t-case and transmission out:

Saturday (15 hrs):

With help, and a very tall floor jack (or a bunch of bricks

Bolt AA adapter to engine:

Bolt adapter to torque converter and install:

I had to grind down the three bolts in order to get them flush w/ the adapter. Not sure if AA dropped the ball or what.

Bolt up trans:

Bolt up t-case:

Connect TV linkage:

Reroute cooler lines. I used rubber for now. I plan to replace with either braided stainless or hard lines. I had ordered the Bowtie overdrives lines, but they aren't long enough to reach the drivers side tank of the stock radiator, nor are they the right fittings for the radiator.

Sunday (10 hrs):

Wire up shifter. I brought the wires that went to the shift position switch on the 5R through the same hole as the shift cable. By rewraping the wire harness correctly, i didn't have to extend any wires, which was nice.

Wire up torque converter harness. I got bowties harness w/ manual lockup switch, and replaced my shifter handle with one that has a switch. so now I can lock the converter up when i'm climbing in 3rd gear. It works great.

Connect shifter, fill trans and start engine w/o exhaust Y-pipe to get neighbors attention

Modify exhaust. I had to crush the pre-cat on the passenger side in order to get the Y-pipe to fit. The O2 sensor on that side is fine. The O2 sensor on the other side clears the adapter plate by a 1/32", so others may need to grind the adapter to get it to fit. I figured I'd then drive it to an exhaust shop and have them remake my Y-pipe to fit better. However I found out that for such a new vehicle the O2 sensors and pre-cats have to be exact stock distances down the pipe to follow guidlines so no one wanted to help me there. I even talked with the local guy for a good 30 mins coming up with crazy ideas to get it to work, like remoting the oil filter and taking the exhaust around the outside of the frame rail. I ended up just using the tube that AA suplies to extend the Y-pipe so that the cats would bolt up sqaure and clear the trans. I may get to have fun when I need to smog this thing

exhaust pics:

I know I've left out many details, so if anyone has any questions, ask away.

But I guess with the pump not running it spun itself dry?

But I guess with the pump not running it spun itself dry?  Yay!

Yay!