KPT

Explorer Addict

- Joined

- February 5, 2003

- Messages

- 1,550

- Reaction score

- 2

- City, State

- NC

- Year, Model & Trim Level

- '95 XL 4x4

AKA M5OD and I've also seen it called Toyo Kogyo.

My tranny had been hard to shift for the last 60k. The entire hydraulic system had been replaced twice and the clutch itself had been replaced one. I finally pulled the damn thing and took it apart.

This is what I found:

The syncro rings were probably fine but I replaced them anyway.

I think these are some of the new:

And these some of the old:

This thread assumes your tranny is currently like this:

I had not intended to write a how to but there just isn't a good one online.

If you need help getting it apart there are threads here and here.

Start by putting the main shaft in a vice. You'll notice I'm using an old sock to protect it. There is already one new bearing on it too. It is right above the lip that is just above the sock. Its a good idea to rub some ATF on all the bearings before you install them:

Second gear goes on next:

Followed by the syncro ring:

The syncro hub/ring goes on next.

The sleeve is directional. The reference dot faces up in this orientation or towards the back of the tranny normally oriented. This hub is not directional if you happened to disassemble the hub/sleeve.

Find this bearing and collar next. The bearing is identical to the first one you put on:

The bearing goes on the collar and into first gear:

Next put the ring on the gear:

And slide it on the main/output shaft:

This bearing needs to be pressed on next. I took it to a machine shop as I don't have a press:

Get the bearing pressed onto the input shaft at the same time as well.

Your main/output shaft should look like this now. This is everything that gets assembled on this side with the shaft out of the case:

Flip the shaft over in the vise now:

This bearing goes on next, you are prelubing all the bearings with ATF right?

Now put third gear on:

The ring can go on next or you can put it on the hub/slider assembly. Note your original third gear ring will probably look like the one on the left:

My replacement kit didn't have one like that. I called the place I bought it and was assured it would be fine.

Put the hub/slider on next. Note both the hub and the slider are directional. This side faces down or towards the rear of the tranny:

This side faces up or towards the front of the tranny. Notice the chamfer on the slider too. That side has to be up:

Now find these pieces:

The inner piece goes on first, the shaft is keyed to it:

Next put this bearing:

This snap ring goes on next:

Mine was tight but if yours feels loose you need to measure the end play and get a thicker snap ring. Consult the FSM for that.

Find this needle bearing and put it in the input shaft. Notice the other bearing you should have pressed on already:

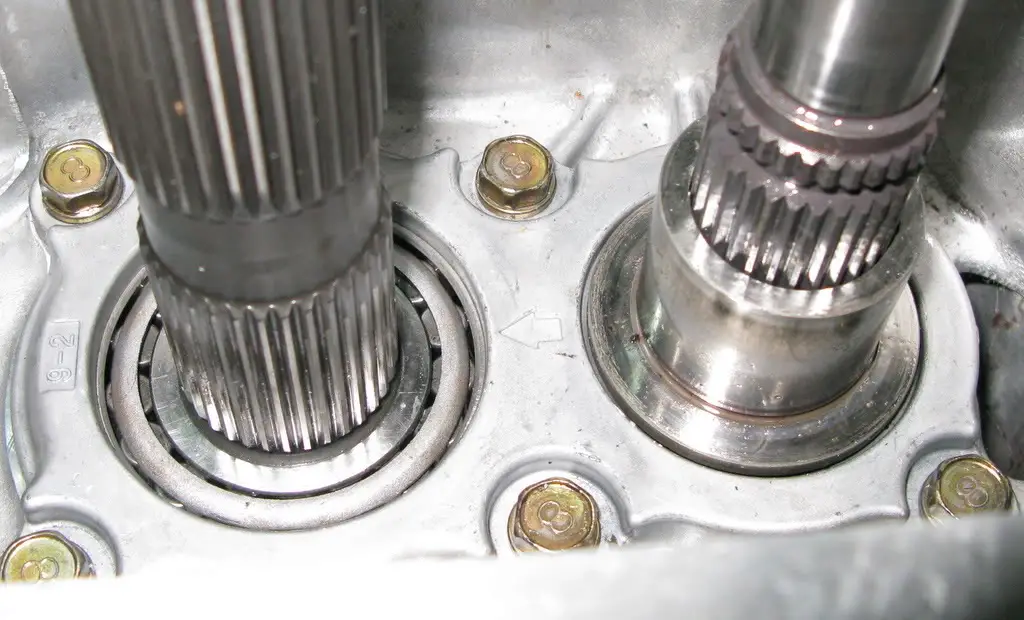

Put the counter shaft and input shaft in the case like this. Note there are two inner bearing races pressed onto the counter shaft. Mine were fine so I did not swap them:

Put the fourth "gear" ring on the main shaft:

And put it in the case like so:

Find your main bearing races. I think the larger one is the output shaft race but don't quote me:

Install the output shaft race and then the counter shaft bearing. You should be able to wiggle each shaft and the race/bearing should just slide in. Do not put them in all the way, let the bearing retainer push them in the last bit. You'll be taking this apart again if they are in too far when you can't get meaningful measurements on the front side:

Both installed:

Rear bearing retainer:

Installed:

Now come around to the front side:

Funny, it feels like we just did this:

Now take this measurment (A):

And this one (C):

Perhaps this one too (D):

Why not one more (B):

Per the FSM:

Find the right amount of shims for the input bearing race:

You can see the tolerances from the FSM in this pic and notice how it says install shim this side out? It means the chamfer on the thickest shim goes out in the sense of the front bearing retainer, NOT in the sense of the transmission. Don't ask how I found out:

Its kinda hard to see but there is the chamfer:

Find the countershaft shim. I got lucky and didn't need to replace it although it was at 0.24mm of a 0.25mm tolerance:

Put the oil baffle in and some grease to hold it together while you turn it upside down. This is an example of WAY too much grease. I wiped most of it off later. Also notice the little trough at the bottom left of this pic. Keep that clean, that is where ATF flows in from the case:

Cleaned up:

The FSM said to wrap the splines so you don't damage the seal:

Don't forget this little plastic piece of **** oil slinger. I did and had to take the retainer back off when I found it in the parts box. Turn it while its down there and it will lock into place:

I apparently was too far in the pint glasses to get a pic of this but put a small line of RTV (making sure not to get any in that ATF trough) and bolt the front bearing retainer on.

With the tranny on its side find this ball and collar:

The ball goes here:

And then the collar slides on:

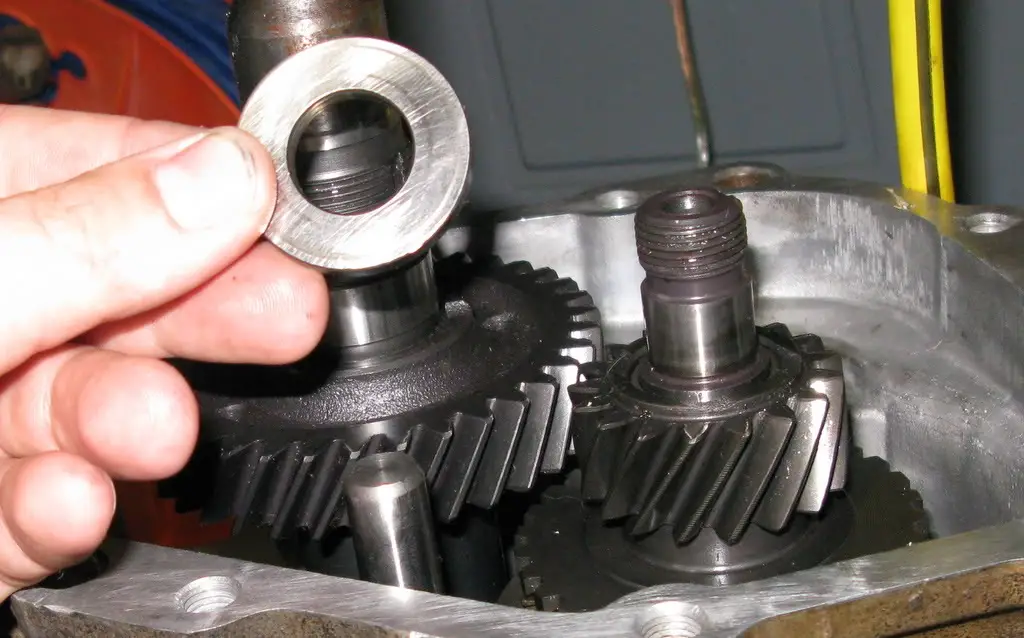

Put the two piece bearing in the fifth countershaft gear and slide it on the collar:

This is the main shaft fifth gear. The longer side goes toward the front of the tranny:

Perhaps it goes here?

Now find this. The rebuild kit comes with a new o-ring for it:

It goes here:

Stick the fifth/reverse shift lever on it. The wider end goes up top:

Another pic I apparently missed but this washer and snap ring hold the two together:

Put some RTV on the bolt and bolt it in. I don't think this one actually needs RTV but the FSM said to so.......

Now put all this together:

And slide it in:

You may have to push it down to get the bolt hole to line up:

This is the bolt and you need RTV on this one:

Now find these pieces:

Two here:

And the retainer over them. The syncro ring and bearings for the reverse gear seem to have joined the party:

This collar goes on the main shaft:

Put this reverse gear on the counter shaft:

The longer flange on the main shaft reverse gear faces the front of the tranny:

This spacer goes on the counter shaft:

Pour some ATF in the bearing of the reverse idler:

RTV the bolt:

And bolt in the reverse idler assembly:

The counter shaft bearing just slides on:

Hand tighten the nut on it:

The output/main shaft bearing has to be pressed on:

Until the gear under it doesn't move up:

Should be hereish:

Now lock the tranny into first and third:

Torque the counter shaft nut:

And guess on the main shaft nut:

Stake them in place:

Clean the transfer case mounting side of the housing if you desire. Probably not necessary as its not sealed. Notice the drain at the bottom of the housing:

Do clean the mating surfaces well. That plastic cap goes in the hole right below it:

Pour some ATF in the bearings and RTV up the mating surface:

You'll have to tap the housing on with a mallet to get the bearings seated in it, then bolt it together:

If you haven't already, pull the rubber plugs out of the top cover and hammer in the freeze plugs that came with the rebuild kit:

Put this rubber gasket in:

Bolt the top cover on and you are done:

My tranny had been hard to shift for the last 60k. The entire hydraulic system had been replaced twice and the clutch itself had been replaced one. I finally pulled the damn thing and took it apart.

This is what I found:

The syncro rings were probably fine but I replaced them anyway.

I think these are some of the new:

And these some of the old:

This thread assumes your tranny is currently like this:

I had not intended to write a how to but there just isn't a good one online.

If you need help getting it apart there are threads here and here.

Start by putting the main shaft in a vice. You'll notice I'm using an old sock to protect it. There is already one new bearing on it too. It is right above the lip that is just above the sock. Its a good idea to rub some ATF on all the bearings before you install them:

Second gear goes on next:

Followed by the syncro ring:

The syncro hub/ring goes on next.

The sleeve is directional. The reference dot faces up in this orientation or towards the back of the tranny normally oriented. This hub is not directional if you happened to disassemble the hub/sleeve.

Find this bearing and collar next. The bearing is identical to the first one you put on:

The bearing goes on the collar and into first gear:

Next put the ring on the gear:

And slide it on the main/output shaft:

This bearing needs to be pressed on next. I took it to a machine shop as I don't have a press:

Get the bearing pressed onto the input shaft at the same time as well.

Your main/output shaft should look like this now. This is everything that gets assembled on this side with the shaft out of the case:

Flip the shaft over in the vise now:

This bearing goes on next, you are prelubing all the bearings with ATF right?

Now put third gear on:

The ring can go on next or you can put it on the hub/slider assembly. Note your original third gear ring will probably look like the one on the left:

My replacement kit didn't have one like that. I called the place I bought it and was assured it would be fine.

Put the hub/slider on next. Note both the hub and the slider are directional. This side faces down or towards the rear of the tranny:

This side faces up or towards the front of the tranny. Notice the chamfer on the slider too. That side has to be up:

Now find these pieces:

The inner piece goes on first, the shaft is keyed to it:

Next put this bearing:

This snap ring goes on next:

Mine was tight but if yours feels loose you need to measure the end play and get a thicker snap ring. Consult the FSM for that.

Find this needle bearing and put it in the input shaft. Notice the other bearing you should have pressed on already:

Put the counter shaft and input shaft in the case like this. Note there are two inner bearing races pressed onto the counter shaft. Mine were fine so I did not swap them:

Put the fourth "gear" ring on the main shaft:

And put it in the case like so:

Find your main bearing races. I think the larger one is the output shaft race but don't quote me:

Install the output shaft race and then the counter shaft bearing. You should be able to wiggle each shaft and the race/bearing should just slide in. Do not put them in all the way, let the bearing retainer push them in the last bit. You'll be taking this apart again if they are in too far when you can't get meaningful measurements on the front side:

Both installed:

Rear bearing retainer:

Installed:

Now come around to the front side:

Funny, it feels like we just did this:

Now take this measurment (A):

And this one (C):

Perhaps this one too (D):

Why not one more (B):

Per the FSM:

Find the right amount of shims for the input bearing race:

You can see the tolerances from the FSM in this pic and notice how it says install shim this side out? It means the chamfer on the thickest shim goes out in the sense of the front bearing retainer, NOT in the sense of the transmission. Don't ask how I found out:

Its kinda hard to see but there is the chamfer:

Find the countershaft shim. I got lucky and didn't need to replace it although it was at 0.24mm of a 0.25mm tolerance:

Put the oil baffle in and some grease to hold it together while you turn it upside down. This is an example of WAY too much grease. I wiped most of it off later. Also notice the little trough at the bottom left of this pic. Keep that clean, that is where ATF flows in from the case:

Cleaned up:

The FSM said to wrap the splines so you don't damage the seal:

Don't forget this little plastic piece of **** oil slinger. I did and had to take the retainer back off when I found it in the parts box. Turn it while its down there and it will lock into place:

I apparently was too far in the pint glasses to get a pic of this but put a small line of RTV (making sure not to get any in that ATF trough) and bolt the front bearing retainer on.

With the tranny on its side find this ball and collar:

The ball goes here:

And then the collar slides on:

Put the two piece bearing in the fifth countershaft gear and slide it on the collar:

This is the main shaft fifth gear. The longer side goes toward the front of the tranny:

Perhaps it goes here?

Now find this. The rebuild kit comes with a new o-ring for it:

It goes here:

Stick the fifth/reverse shift lever on it. The wider end goes up top:

Another pic I apparently missed but this washer and snap ring hold the two together:

Put some RTV on the bolt and bolt it in. I don't think this one actually needs RTV but the FSM said to so.......

Now put all this together:

And slide it in:

You may have to push it down to get the bolt hole to line up:

This is the bolt and you need RTV on this one:

Now find these pieces:

Two here:

And the retainer over them. The syncro ring and bearings for the reverse gear seem to have joined the party:

This collar goes on the main shaft:

Put this reverse gear on the counter shaft:

The longer flange on the main shaft reverse gear faces the front of the tranny:

This spacer goes on the counter shaft:

Pour some ATF in the bearing of the reverse idler:

RTV the bolt:

And bolt in the reverse idler assembly:

The counter shaft bearing just slides on:

Hand tighten the nut on it:

The output/main shaft bearing has to be pressed on:

Until the gear under it doesn't move up:

Should be hereish:

Now lock the tranny into first and third:

Torque the counter shaft nut:

And guess on the main shaft nut:

Stake them in place:

Clean the transfer case mounting side of the housing if you desire. Probably not necessary as its not sealed. Notice the drain at the bottom of the housing:

Do clean the mating surfaces well. That plastic cap goes in the hole right below it:

Pour some ATF in the bearings and RTV up the mating surface:

You'll have to tap the housing on with a mallet to get the bearings seated in it, then bolt it together:

If you haven't already, pull the rubber plugs out of the top cover and hammer in the freeze plugs that came with the rebuild kit:

Put this rubber gasket in:

Bolt the top cover on and you are done: