2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,597

- Reaction score

- 334

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

Oil Coolers w Lessons Learned

Begin Lessons Learned

To save you the time of reading this long thread and to prevent you from duplicating modifications that were later determined to be undesireable I've added this section.

General

1. Remote oil filters and coolers can increase engine and transmission life by reducing oil particles and maximum fluid temperatures but may also reduce reliability due to additional plumbing. Flexible hoses are easier to work with than rigid tubing but are heavier, have lower temperature and pressure specifications, larger minimum bend radius and deteriorate with age. Hoses routed near exhaust components should be protected with heat resistant sheathing. Hoses in contact with abrasive surfaces should be protected (I cut and slit larger diameter heater hose to fit over the oil hose). Hoses with short bend radius should be reinforced to prevent kinking (larger diameter heater hose). Push-loc/twist-lok) hose with hose clamps increase reliability. Perforated hose clamps damage hoses. I used fuel line hose clamps on 3/8 inch internal diameter ATF hoses and non-perforated stainless steel hose clamps on 1/2 inch internal diameter engine oil hoses. Components should be installed where they are damage protected from off-road hazards and hydraulic lifts. Most of my components are mounted behind the bumper and front grille and hose runs to the engine and transmission are above the bottom of the frame.

2. Brass fittings are fairly expensive (>$200 for my installation) and heavy. Thoughtful planning and selection of the optimum remote filter adapter configuration (2 ports vs 4 ports, vertical vs horizontal ports, left vs right ports) can significantly reduce the number of fittings. Flare (AN) type fittings are also fairly expensive but weigh less than brass fittings. Pipe threads should be sealed with Teflon tape or thread sealer. I experienced leaks with Teflon tape and eventually used high temperature thread sealer on all pipe threads. Flare fittings are subject to loosening from vibration. There are wire locks on my thermostat -12 O ring to -08 AN male adapters. I used thread lock on the other AN fittings.

3. For accurate readings oil temperature sensors should be mounted horizontally or inverted to prevent air pockets and where oil flow is not stagnant.

Engine oil cooler

1. For normal driving conditions an external engine oil cooler is not needed. During short city drives the engine oil temperature rarely reaches optimum.

2. An engine oil cooler without thermostatic control should not be installed (especially in cold weather climates). The engine oil should reach optimum temperature as soon as possible for better lubrication, reduced friction (better fuel economy and power) and sludge reduction. The optimum engine oil temperature is high enough to eliminate water vapor (> 212 Deg F) while low enough to prevent breakdown. I used a 215 degrees F. thermostat from Canton Racing.

3. The engine oil should not be routed thru the radiator internal oil cooler. According to my remote reading temperature sensor even in warm weather the temperature of the radiator oil cooler is less than 150 degrees F.

Engine oil remote filters

1. Separation of oil filter from the block increases cooling reducing oil temperature.

2. If only one filter is utilized it should be a high flow filter.

3. Filter(s) mounted vertically and upright will not drain reducing "dry starts".

4. Filter(s) mounted vertically and downward (or at a large angle) should contain a quality check valve to prevent drainage.

5. When installing a second low flow/high filtration filter it must be in parallel with the primary high flow filter. Since it has less flow it will take longer to filter all of the oil.

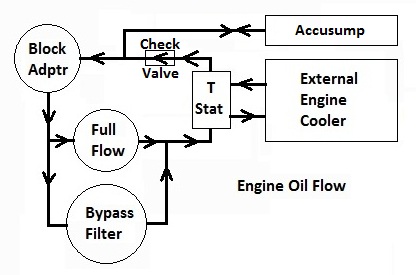

Engine pre-oiler

If an Accusump is incorporated a check valve should be installed in the return oil path to direct oil from the Accusump only into the block adapter inlet.

ATF oil cooler

1. For normal driving conditions the radiator internal ATF cooler and one external engine oil cooler is adequate.

2. The 5R55E transmission has an internal thermistor that provides the PCM with transmission fluid temperature (TFT). The PCM uses the TFT to determine whether cold start shift schedule (quicker shifts) is necessary. The PCM also adjusts EPC pressure for TFT. The 5R55E also has an internal thermostat that opens the external cooling loop when the torque converter temperature reaches 150 degrees F. Ford apparently has determined that 150 degrees is optimum. It takes about twenty minutes of driving for the torque converter temperature to reach 150 degrees F. Some members modify the valve body to permanently keep the external cooling open defeating the benefits of the design. The lower external cooling loop port is perpendicular to the case and the upper one is at a 45 degree angle to the case pointing forward. The lower one (rear fitting) is the return port and the upper one (front fitting) is the supply port.

3. Best ATF cooling is achieved by routing the transmission external cooling loop output to the radiator internal oil cooler and then to external air coolers and back to the transmission. Even though in summer the temperature of the radiator cooler is typically greater than ambient air temperature, liquid to liquid heat transfer is many times greater than liquid to air heat transfer for a specific temperature. Auxiliary coolers are mounted in front of the radiator and encounter cooler air than the radiator and A/C condenser. If the radiator coolant exceeds 150 degrees F then the auxiliary coolers can lower the ATF temperature. There is no concern during cold weather operation that the ATF temperature will be too low because the transmission internal thermostat will not allow flow thru the external cooling loop if the temperature is less than 150 degrees F. Auxiliary coolers (excluding the radiator cooler) should be in parallel to reduce flow resistance. The closer an auxiliary cooler is mounted to the A/C condenser the more effective it will be at low vehicle speeds because more air will be pulled thru the cooler by the radiator fan.

ATF Remote Filter

1. The increase in area exposed to ambient temperature increases cooling reducing ATF temperature. A "fin" kit may be available to increase the cooling of the filter.

2. The filter is only effective when the external cooling loop is open.

3. A full flow filter should be utilized to reduce flow restriction. The more the restriction the less cooling from the radiator intank ATF cooler and any auxiliary cooler(s).

4. The filter can be connected directly to the 5R55E outlet port or input port. If a temperature sensor is mounted on the filter housing ports it can monitor 5R55E outlet temperature of inlet temperature depending on where in the loop the filter is connected. If the filter is connected to the 5R55E outlet port it will eliminate metal fragments from the coolers. If connected to the inlet port it will still prevent metal fragments from returning to the transmission. I prefer connecting to the outlet port allowing constant monitoring of the ATF temperature without tying up the OBD port.

End Lessons Learned

I recently read several threads regarding transmission oil coolers. I was thrilled to learn that my 5R55E internally recirculates the transmission oil until it reaches operating temperature. It is only after the operating temperature is achieved that oil is allowed to flow to the external cooler(s).

I also did some internet research on engine oil coolers and the importance of maintaining the optimum oil temperature. I remember that my 1964 Alfa 2600 Spider had an external temperature controlled oil cooler and decided I want something similar on my Sport. The optimum engine oil temperature appears to be 180 to 200 degrees F - about the same as the standard engine coolant thermostat.

So this is my idea.

1. Replace the stock oil filter with a remote engine oil filter/oil cooler engine block adapter.

2. Disconnect the transmission oil lines from the transmission oil cooler in the radiator.

3. Disconnect the transmission oil lines from the auxiliary transmission oil cooler mounted in front of the air conditioner condenser.

4. Route an engine oil line from the adapter outlet to the remote oil filter inlet.

5. Route an engine oil line from the remote oil filter outlet to the previously auxiliary transmission oil cooler inlet.

6. Route an engine oil line from the previously auxiliary transmission oil cooler outlet to the radiator internal previously transmission oil cooler inlet.

7. Route an engine oil line from the radiator internal previously transmission oil cooler outlet to the remote engine oil filter/oil cooler engine block adapter inlet.

8. Mount a large new transmission oil cooler in front of the air conditioner condenser.

9. Route transmission oil lines from the new transmission oil cooler to the transmission.

The results of the above should be:

1. Improved engine oil temperature regulation (reduced maximum) due to the external oil cooler.

2. Improved engine oil temperature regulation (increased minimum) due to radiator internal oil cooler.

3. Improved transmission oil temperature regulation (reduced maximum) due to increased capacity.

Begin Lessons Learned

To save you the time of reading this long thread and to prevent you from duplicating modifications that were later determined to be undesireable I've added this section.

General

1. Remote oil filters and coolers can increase engine and transmission life by reducing oil particles and maximum fluid temperatures but may also reduce reliability due to additional plumbing. Flexible hoses are easier to work with than rigid tubing but are heavier, have lower temperature and pressure specifications, larger minimum bend radius and deteriorate with age. Hoses routed near exhaust components should be protected with heat resistant sheathing. Hoses in contact with abrasive surfaces should be protected (I cut and slit larger diameter heater hose to fit over the oil hose). Hoses with short bend radius should be reinforced to prevent kinking (larger diameter heater hose). Push-loc/twist-lok) hose with hose clamps increase reliability. Perforated hose clamps damage hoses. I used fuel line hose clamps on 3/8 inch internal diameter ATF hoses and non-perforated stainless steel hose clamps on 1/2 inch internal diameter engine oil hoses. Components should be installed where they are damage protected from off-road hazards and hydraulic lifts. Most of my components are mounted behind the bumper and front grille and hose runs to the engine and transmission are above the bottom of the frame.

2. Brass fittings are fairly expensive (>$200 for my installation) and heavy. Thoughtful planning and selection of the optimum remote filter adapter configuration (2 ports vs 4 ports, vertical vs horizontal ports, left vs right ports) can significantly reduce the number of fittings. Flare (AN) type fittings are also fairly expensive but weigh less than brass fittings. Pipe threads should be sealed with Teflon tape or thread sealer. I experienced leaks with Teflon tape and eventually used high temperature thread sealer on all pipe threads. Flare fittings are subject to loosening from vibration. There are wire locks on my thermostat -12 O ring to -08 AN male adapters. I used thread lock on the other AN fittings.

3. For accurate readings oil temperature sensors should be mounted horizontally or inverted to prevent air pockets and where oil flow is not stagnant.

Engine oil cooler

1. For normal driving conditions an external engine oil cooler is not needed. During short city drives the engine oil temperature rarely reaches optimum.

2. An engine oil cooler without thermostatic control should not be installed (especially in cold weather climates). The engine oil should reach optimum temperature as soon as possible for better lubrication, reduced friction (better fuel economy and power) and sludge reduction. The optimum engine oil temperature is high enough to eliminate water vapor (> 212 Deg F) while low enough to prevent breakdown. I used a 215 degrees F. thermostat from Canton Racing.

3. The engine oil should not be routed thru the radiator internal oil cooler. According to my remote reading temperature sensor even in warm weather the temperature of the radiator oil cooler is less than 150 degrees F.

Engine oil remote filters

1. Separation of oil filter from the block increases cooling reducing oil temperature.

2. If only one filter is utilized it should be a high flow filter.

3. Filter(s) mounted vertically and upright will not drain reducing "dry starts".

4. Filter(s) mounted vertically and downward (or at a large angle) should contain a quality check valve to prevent drainage.

5. When installing a second low flow/high filtration filter it must be in parallel with the primary high flow filter. Since it has less flow it will take longer to filter all of the oil.

Engine pre-oiler

If an Accusump is incorporated a check valve should be installed in the return oil path to direct oil from the Accusump only into the block adapter inlet.

ATF oil cooler

1. For normal driving conditions the radiator internal ATF cooler and one external engine oil cooler is adequate.

2. The 5R55E transmission has an internal thermistor that provides the PCM with transmission fluid temperature (TFT). The PCM uses the TFT to determine whether cold start shift schedule (quicker shifts) is necessary. The PCM also adjusts EPC pressure for TFT. The 5R55E also has an internal thermostat that opens the external cooling loop when the torque converter temperature reaches 150 degrees F. Ford apparently has determined that 150 degrees is optimum. It takes about twenty minutes of driving for the torque converter temperature to reach 150 degrees F. Some members modify the valve body to permanently keep the external cooling open defeating the benefits of the design. The lower external cooling loop port is perpendicular to the case and the upper one is at a 45 degree angle to the case pointing forward. The lower one (rear fitting) is the return port and the upper one (front fitting) is the supply port.

3. Best ATF cooling is achieved by routing the transmission external cooling loop output to the radiator internal oil cooler and then to external air coolers and back to the transmission. Even though in summer the temperature of the radiator cooler is typically greater than ambient air temperature, liquid to liquid heat transfer is many times greater than liquid to air heat transfer for a specific temperature. Auxiliary coolers are mounted in front of the radiator and encounter cooler air than the radiator and A/C condenser. If the radiator coolant exceeds 150 degrees F then the auxiliary coolers can lower the ATF temperature. There is no concern during cold weather operation that the ATF temperature will be too low because the transmission internal thermostat will not allow flow thru the external cooling loop if the temperature is less than 150 degrees F. Auxiliary coolers (excluding the radiator cooler) should be in parallel to reduce flow resistance. The closer an auxiliary cooler is mounted to the A/C condenser the more effective it will be at low vehicle speeds because more air will be pulled thru the cooler by the radiator fan.

ATF Remote Filter

1. The increase in area exposed to ambient temperature increases cooling reducing ATF temperature. A "fin" kit may be available to increase the cooling of the filter.

2. The filter is only effective when the external cooling loop is open.

3. A full flow filter should be utilized to reduce flow restriction. The more the restriction the less cooling from the radiator intank ATF cooler and any auxiliary cooler(s).

4. The filter can be connected directly to the 5R55E outlet port or input port. If a temperature sensor is mounted on the filter housing ports it can monitor 5R55E outlet temperature of inlet temperature depending on where in the loop the filter is connected. If the filter is connected to the 5R55E outlet port it will eliminate metal fragments from the coolers. If connected to the inlet port it will still prevent metal fragments from returning to the transmission. I prefer connecting to the outlet port allowing constant monitoring of the ATF temperature without tying up the OBD port.

End Lessons Learned

I recently read several threads regarding transmission oil coolers. I was thrilled to learn that my 5R55E internally recirculates the transmission oil until it reaches operating temperature. It is only after the operating temperature is achieved that oil is allowed to flow to the external cooler(s).

I also did some internet research on engine oil coolers and the importance of maintaining the optimum oil temperature. I remember that my 1964 Alfa 2600 Spider had an external temperature controlled oil cooler and decided I want something similar on my Sport. The optimum engine oil temperature appears to be 180 to 200 degrees F - about the same as the standard engine coolant thermostat.

So this is my idea.

1. Replace the stock oil filter with a remote engine oil filter/oil cooler engine block adapter.

2. Disconnect the transmission oil lines from the transmission oil cooler in the radiator.

3. Disconnect the transmission oil lines from the auxiliary transmission oil cooler mounted in front of the air conditioner condenser.

4. Route an engine oil line from the adapter outlet to the remote oil filter inlet.

5. Route an engine oil line from the remote oil filter outlet to the previously auxiliary transmission oil cooler inlet.

6. Route an engine oil line from the previously auxiliary transmission oil cooler outlet to the radiator internal previously transmission oil cooler inlet.

7. Route an engine oil line from the radiator internal previously transmission oil cooler outlet to the remote engine oil filter/oil cooler engine block adapter inlet.

8. Mount a large new transmission oil cooler in front of the air conditioner condenser.

9. Route transmission oil lines from the new transmission oil cooler to the transmission.

The results of the above should be:

1. Improved engine oil temperature regulation (reduced maximum) due to the external oil cooler.

2. Improved engine oil temperature regulation (increased minimum) due to radiator internal oil cooler.

3. Improved transmission oil temperature regulation (reduced maximum) due to increased capacity.