drdoom

Explorer Addict

- Joined

- December 13, 2007

- Messages

- 4,582

- Reaction score

- 340

- City, State

- VA

- Year, Model & Trim Level

- 2005 Eddie Bauer 4.6L 4X4

The vehicle: 1997 Explorer XLT 4WD 4.0 SOHC w/ towing package, 174,000 miles.

What happened: O/D OFF light was flashing intermittently, and before I could get it in to have the codes read, the transmission overheated due to a problem with the Torque Converter Clutch System. As I later discovered, the vent tube was plugged on the atmosphere side, and so when the transmission overheated, ATF was forced out through the two tiny holes in the apex of the vent tube, sending a shower of ATF onto the hot exhaust, causing a serious vehicle fire. Upon getting the vehicle into the shop, it was found to be storing a P0741 code: Torque Converter Clutch System stuck off. Tricky thing is, this vehicle performed fine during two separate 20 mile test drives, AFTER the fire!

Due to the high mileage & age of the vehicle, I was keeping this project on a very tight budget.

Now, I don't know squat about automatic transmissions, so I spent several long nights researching here on Explorer Forum, as well as many other pages I found with Google. After an extensive amount of research & study, I had a "plan".

My plan was to remove the transmission for a thorough inspection, and order whatever parts I deemed necessary. My research was telling me that code P0741 is a cryptic & devious devil, with several possible causes. I knew that there was no torque converter lock-up, but that could be due to a solenoid problem, the internal thermostat, a hydraulic problem, or even worn bores, seals, or some combination thereof. It could even be the torque converter alone, as the F57 Torque Converter is prone to wear in the piston hub.

What I found:

Fluid was badly burnt, with metallic fines present.

Valve body gaskets were original, and in good shape.

Valve body was original, with no upgrades.

All six solenoids passed resistance tests, for what that's worth...

Transmission pan had some sludge, and some minute metal shavings.

Transmission internals were in great shape, even the friction packs & bands looked good.

Here are some photos, and a bit of an explanation about my repairs.

Here is the transmission, after removing the metal vent tube.

Here is a close-up of the Digital Transmission Range sensor.

Also visible to the left is the 16-pin connector.

Pump & input shaft shown below:

Front Brake & Coast Clutch Drum shown below:

And retaining ring pulled, to access friction pack:

Clutches & Steels:

And the Forward Gear Train Assembly, shown assembled:

The Center Support, showing the Turbine Shaft Speed sensor at the five-o-clock position:

And here is a shot down deep, showing the reverse drum, output shaft ring gear, thrust washer, & plastic cone:

Reverse band:

Output shaft:

Intermediate servo being removed...

And a shot showing my homemade servo cover tool:

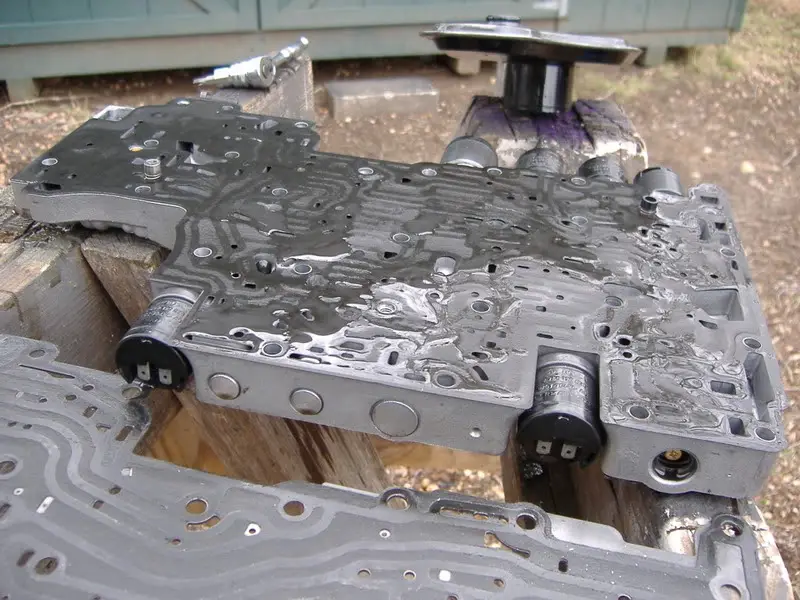

Here is the original valve body, with the separator plate visible in the foreground. After reading so many threads about blown gaskets, I was hoping, early on, that this was the extent of my problem. It was not, as the gaskets here were in good shape:

Here is a shot of the case, with the linkage coming out:

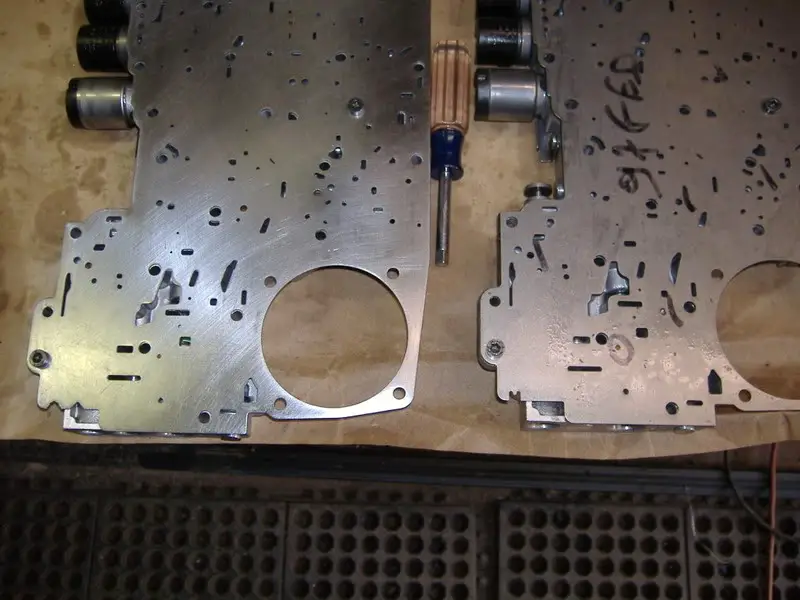

OK, next a few shots of the valve bodies, updated on the left, original on the right. Please note the notches in the lower left corner of the separator plates...they are notched differently, which is some type of ID system. Also, the updated valve body came with a used bonded separator plate, and I had paper gaskets on hand. So I scraped the bonded gaskets off, then wet sanded the plate to 220 grit, as to accept the paper gaskets provided in my overhaul kit. NOTE: The plates are not interchangeable, as the updated plate has a hole deleted (where the spring loaded relief valve was deleted).

Next you can see the blow-off valve (left unit):

And on the pan side you can see some obvious differences in the casting, as well as the reinforced solenoid retaining brackets:

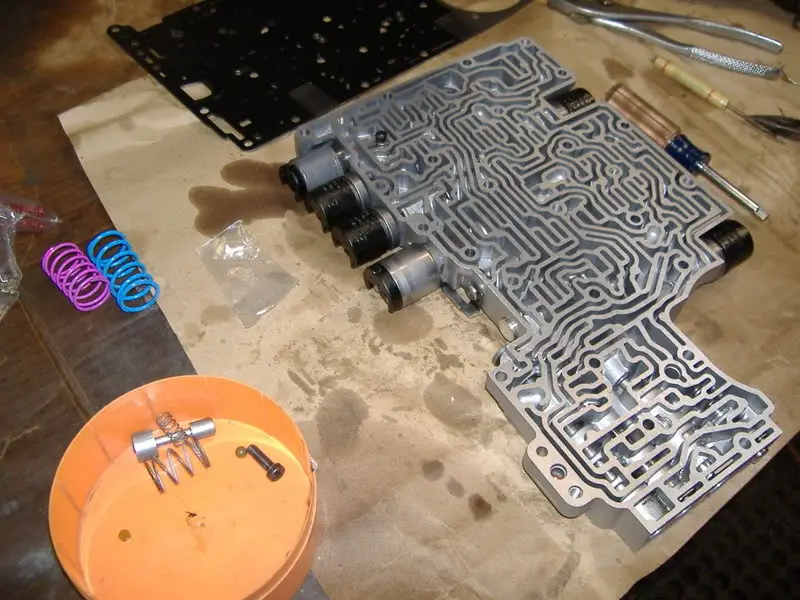

And here is the updated valve body with the separator plate removed, where you can see it is devoid of the EPC screen and the other spring loaded relief valve. Also visible are a few of the parts out of the Superior Shift Kit, which I installed as the Heavy Duty version. The kit installation involves changing out a few spools & springs, enlarging a couple of holes in the separator plate, a thermal bypass, a pressure riser that splices into the internal wiring harness (tricky, as the space is VERY limited!), a new servo spring, a new "D" ring for the reverse servo, and some new springs for one of the clutch packs:

And here is my Shade Tree Clutch Spring Compressor, comprised of three 1/2" drive sockets, and three Quick-Grip clamps. This is simple, and very effective, as it is necessary when overhauling the clutch pistons:

Here is a shot of the new red springs from the Superior Shift Kit going in:

Here is a shot of the pump & stator, with the old style "scarf-cut" seal visible on the end of the stator. The stator seal is a problem area on the 5R55E, and TransTec provides an updated seal, a new material called QUANTUM. It appears to be a type of TEFLON seal, and are a little tricky to work with. TEFLON seals have to stretch a bit as they are pushed onto the shaft, but they don't spring right back like an O-ring does. So they have to be re-sized once they are in position. All that info is in the manual, tool numbers, etc. I improvised using cable ties, pieces cut out of an empty windshield washer jug. The pieces from the jug are useful as both a seal protector sleeve covering the splines on the turbine shaft, and also wrapped with cable ties around the seals to re-size them (the LipWizard tool that comes with TransTec kits, although not intended for this purpose, can also be used in this role). You have to be very careful not to nick or cut those seals. If they are not re-sized fully, they are very prone to being damaged during the installation of subsequent components, as the tolerances are very tight. Shade Tree Tip: Not having a pump alignment tool set, I devised the following method: Invert a 5 gallon drywall bucket, and set the new torque converter on top of it, flex-plate side down. And with the pump loosely attached to the converter housing, lower the stator into the new torque converter to align it, and then torque the six pump to housing bolts. Remove pump & housing.

Here is a shot of some of the seals that come in the TransTec Overhaul Kit, the old style metal on the top, and the new updated material on the bottom:

Here is a view of the cleaned case, with the TSS wiring visible, and the reverse servo temporarily installed:

And here is a shot of the housing being installed, with one of the homemade alignment pins (bolts with heads cut off, and I made more of the same for valve body alignment) still in place:

And one of my favorite things, a drain plug I added, carefully positioned for maximum drainage, and to not interfere with the filter. I picked this one up at Advance for less than $3.00, and a metric nut from Tractor Supply Company, and drilled the pan, then tacked it in with a MIG:

Here are the lines to and from the towing cooler...I opened the system here, and ran a can of Pro-King Transmission Cooler Flush through BOTH coolers. This is VERY IMPORTANT!!! I was appalled at the amount of metal shavings that came out of both coolers! I cannot stress this enough, that what I saw in the pan was nothing...the bulk of the shavings from my chewed up torque converter were IN THE COOLERS!! It looked bad enough that I went and bought another can of cooler flush, but it may not have been needed since the flush fluid came through clean right away. This rubber line on the right is the return and this is where I installed an inline magnetic filter, a very simple and serviceable installation:

SUMMARY:

Parts:

Re-manufactured torque converter $160.00 (I had $20.00 coupon)

Superior Shift Kit $45.00

Transmission Overhaul Kit $55.00

Updated valve body $163.00

Drain plug $3.50

Transmission Cooler Flush Kits w/ in-line magnetic filters (2) @ $16.00

New in-pan filter $5.00

Exhaust flange gasket $4.00

New bolts for exhaust, both ends $4.00

Mercron V (11) @ $5.00

Dex/Merc for the 4405 (2) @ $4.00

BraKleen (5) @ $3.00

Dielectric grease $3.00

Flame retardant wire Conduits $5.00

EXPENSES: $542.50 (roughly)

Basically, what I did:

Tore everything down, inspected, and cleaned.

Flushed coolers

Added drain plug

Replaced valve body & solenoids

Replaced pan filter

Added in line auxiliary transmission filter

Installed overhaul kit

Installed Superior shift kit

Replaced torque converter

Replaced flame retardant wire conduits

Fresh fluid in transfer case

ADD: Hood release cable needed replacing, as it was damaged in the fire. So add another $50.00 to the total.

O

The truck was ready to go as soon as I got the fluid topped off, and I have since put over 60,000 hard miles on it, including some light towing, with no problems so far. Fluid looks clean and level is holding, no leaks, shifts great (albeit somewhat firm), and no codes.

I have since replaced the auxiliary filter, and after back-draining it, I saw that a little more debris from the coolers had been trapped in there. So that seems to be doing it's job. I have changed the fluid via drain plug also, and visually it was nice and clean.

Thank You for reading.

What happened: O/D OFF light was flashing intermittently, and before I could get it in to have the codes read, the transmission overheated due to a problem with the Torque Converter Clutch System. As I later discovered, the vent tube was plugged on the atmosphere side, and so when the transmission overheated, ATF was forced out through the two tiny holes in the apex of the vent tube, sending a shower of ATF onto the hot exhaust, causing a serious vehicle fire. Upon getting the vehicle into the shop, it was found to be storing a P0741 code: Torque Converter Clutch System stuck off. Tricky thing is, this vehicle performed fine during two separate 20 mile test drives, AFTER the fire!

Due to the high mileage & age of the vehicle, I was keeping this project on a very tight budget.

Now, I don't know squat about automatic transmissions, so I spent several long nights researching here on Explorer Forum, as well as many other pages I found with Google. After an extensive amount of research & study, I had a "plan".

My plan was to remove the transmission for a thorough inspection, and order whatever parts I deemed necessary. My research was telling me that code P0741 is a cryptic & devious devil, with several possible causes. I knew that there was no torque converter lock-up, but that could be due to a solenoid problem, the internal thermostat, a hydraulic problem, or even worn bores, seals, or some combination thereof. It could even be the torque converter alone, as the F57 Torque Converter is prone to wear in the piston hub.

What I found:

Fluid was badly burnt, with metallic fines present.

Valve body gaskets were original, and in good shape.

Valve body was original, with no upgrades.

All six solenoids passed resistance tests, for what that's worth...

Transmission pan had some sludge, and some minute metal shavings.

Transmission internals were in great shape, even the friction packs & bands looked good.

Here are some photos, and a bit of an explanation about my repairs.

Here is the transmission, after removing the metal vent tube.

Here is a close-up of the Digital Transmission Range sensor.

Also visible to the left is the 16-pin connector.

Pump & input shaft shown below:

Front Brake & Coast Clutch Drum shown below:

And retaining ring pulled, to access friction pack:

Clutches & Steels:

And the Forward Gear Train Assembly, shown assembled:

The Center Support, showing the Turbine Shaft Speed sensor at the five-o-clock position:

And here is a shot down deep, showing the reverse drum, output shaft ring gear, thrust washer, & plastic cone:

Reverse band:

Output shaft:

Intermediate servo being removed...

And a shot showing my homemade servo cover tool:

Here is the original valve body, with the separator plate visible in the foreground. After reading so many threads about blown gaskets, I was hoping, early on, that this was the extent of my problem. It was not, as the gaskets here were in good shape:

Here is a shot of the case, with the linkage coming out:

OK, next a few shots of the valve bodies, updated on the left, original on the right. Please note the notches in the lower left corner of the separator plates...they are notched differently, which is some type of ID system. Also, the updated valve body came with a used bonded separator plate, and I had paper gaskets on hand. So I scraped the bonded gaskets off, then wet sanded the plate to 220 grit, as to accept the paper gaskets provided in my overhaul kit. NOTE: The plates are not interchangeable, as the updated plate has a hole deleted (where the spring loaded relief valve was deleted).

Next you can see the blow-off valve (left unit):

And on the pan side you can see some obvious differences in the casting, as well as the reinforced solenoid retaining brackets:

And here is the updated valve body with the separator plate removed, where you can see it is devoid of the EPC screen and the other spring loaded relief valve. Also visible are a few of the parts out of the Superior Shift Kit, which I installed as the Heavy Duty version. The kit installation involves changing out a few spools & springs, enlarging a couple of holes in the separator plate, a thermal bypass, a pressure riser that splices into the internal wiring harness (tricky, as the space is VERY limited!), a new servo spring, a new "D" ring for the reverse servo, and some new springs for one of the clutch packs:

And here is my Shade Tree Clutch Spring Compressor, comprised of three 1/2" drive sockets, and three Quick-Grip clamps. This is simple, and very effective, as it is necessary when overhauling the clutch pistons:

Here is a shot of the new red springs from the Superior Shift Kit going in:

Here is a shot of the pump & stator, with the old style "scarf-cut" seal visible on the end of the stator. The stator seal is a problem area on the 5R55E, and TransTec provides an updated seal, a new material called QUANTUM. It appears to be a type of TEFLON seal, and are a little tricky to work with. TEFLON seals have to stretch a bit as they are pushed onto the shaft, but they don't spring right back like an O-ring does. So they have to be re-sized once they are in position. All that info is in the manual, tool numbers, etc. I improvised using cable ties, pieces cut out of an empty windshield washer jug. The pieces from the jug are useful as both a seal protector sleeve covering the splines on the turbine shaft, and also wrapped with cable ties around the seals to re-size them (the LipWizard tool that comes with TransTec kits, although not intended for this purpose, can also be used in this role). You have to be very careful not to nick or cut those seals. If they are not re-sized fully, they are very prone to being damaged during the installation of subsequent components, as the tolerances are very tight. Shade Tree Tip: Not having a pump alignment tool set, I devised the following method: Invert a 5 gallon drywall bucket, and set the new torque converter on top of it, flex-plate side down. And with the pump loosely attached to the converter housing, lower the stator into the new torque converter to align it, and then torque the six pump to housing bolts. Remove pump & housing.

Here is a shot of some of the seals that come in the TransTec Overhaul Kit, the old style metal on the top, and the new updated material on the bottom:

Here is a view of the cleaned case, with the TSS wiring visible, and the reverse servo temporarily installed:

And here is a shot of the housing being installed, with one of the homemade alignment pins (bolts with heads cut off, and I made more of the same for valve body alignment) still in place:

And one of my favorite things, a drain plug I added, carefully positioned for maximum drainage, and to not interfere with the filter. I picked this one up at Advance for less than $3.00, and a metric nut from Tractor Supply Company, and drilled the pan, then tacked it in with a MIG:

Here are the lines to and from the towing cooler...I opened the system here, and ran a can of Pro-King Transmission Cooler Flush through BOTH coolers. This is VERY IMPORTANT!!! I was appalled at the amount of metal shavings that came out of both coolers! I cannot stress this enough, that what I saw in the pan was nothing...the bulk of the shavings from my chewed up torque converter were IN THE COOLERS!! It looked bad enough that I went and bought another can of cooler flush, but it may not have been needed since the flush fluid came through clean right away. This rubber line on the right is the return and this is where I installed an inline magnetic filter, a very simple and serviceable installation:

SUMMARY:

Parts:

Re-manufactured torque converter $160.00 (I had $20.00 coupon)

Superior Shift Kit $45.00

Transmission Overhaul Kit $55.00

Updated valve body $163.00

Drain plug $3.50

Transmission Cooler Flush Kits w/ in-line magnetic filters (2) @ $16.00

New in-pan filter $5.00

Exhaust flange gasket $4.00

New bolts for exhaust, both ends $4.00

Mercron V (11) @ $5.00

Dex/Merc for the 4405 (2) @ $4.00

BraKleen (5) @ $3.00

Dielectric grease $3.00

Flame retardant wire Conduits $5.00

EXPENSES: $542.50 (roughly)

Basically, what I did:

Tore everything down, inspected, and cleaned.

Flushed coolers

Added drain plug

Replaced valve body & solenoids

Replaced pan filter

Added in line auxiliary transmission filter

Installed overhaul kit

Installed Superior shift kit

Replaced torque converter

Replaced flame retardant wire conduits

Fresh fluid in transfer case

ADD: Hood release cable needed replacing, as it was damaged in the fire. So add another $50.00 to the total.

O

The truck was ready to go as soon as I got the fluid topped off, and I have since put over 60,000 hard miles on it, including some light towing, with no problems so far. Fluid looks clean and level is holding, no leaks, shifts great (albeit somewhat firm), and no codes.

I have since replaced the auxiliary filter, and after back-draining it, I saw that a little more debris from the coolers had been trapped in there. So that seems to be doing it's job. I have changed the fluid via drain plug also, and visually it was nice and clean.

Thank You for reading.