2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,597

- Reaction score

- 334

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

86. Position oil catch pan & remove oil pan drain plug.

87. When oil pan drained install drain plug.

88. Remove the left front wheel & then the fender forward splash shield by prying loose the push pins.

89. Using a 1/2 inch drive with short extension inserted into the serpentine belt tensioner rotate the drive clockwise and disengage the belt from the alternator pulley.

90. Remove belt from all pulleys & set aside.

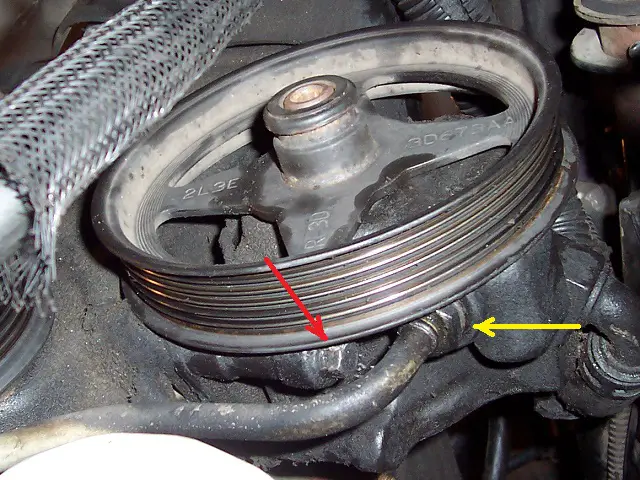

91. Position power steering fluid catch pan & disconnect the power steering high pressure hose at the passenger side (red arrow below).

92. Position power steering fluid catch pan & disconnect the power steering fluid return hose at the cooler (yellow arrow above).

I have determined that it is possible to separate the power steering pump from the power steering fluid reservoir bracket and engine without disconnecting the high pressure pipe fitting at the pump (yellow arrow below) but it is not worth the time and effort.

The 10 mm power steering pump retaining bolt (red arrow above) must be unscrewed in order to separate the power steering pump from the power steering fluid reservoir bracket. The pipe can't be rotated out of the way far enough to extract the bolt. Even if the bolt is completely loosened it will not clear the high pressure pipe. If the pump is rocked away from the bracket and engine as the 10 mm bolt is loosened eventually the pump will separate from the bracket when it clears 2 guide bushings that pass thru the bracket and into the pump. Even then the stud/bolt shown below prevents the bracket from separating from the engine because of the guide bushings.

87. When oil pan drained install drain plug.

88. Remove the left front wheel & then the fender forward splash shield by prying loose the push pins.

89. Using a 1/2 inch drive with short extension inserted into the serpentine belt tensioner rotate the drive clockwise and disengage the belt from the alternator pulley.

90. Remove belt from all pulleys & set aside.

91. Position power steering fluid catch pan & disconnect the power steering high pressure hose at the passenger side (red arrow below).

92. Position power steering fluid catch pan & disconnect the power steering fluid return hose at the cooler (yellow arrow above).

I have determined that it is possible to separate the power steering pump from the power steering fluid reservoir bracket and engine without disconnecting the high pressure pipe fitting at the pump (yellow arrow below) but it is not worth the time and effort.

The 10 mm power steering pump retaining bolt (red arrow above) must be unscrewed in order to separate the power steering pump from the power steering fluid reservoir bracket. The pipe can't be rotated out of the way far enough to extract the bolt. Even if the bolt is completely loosened it will not clear the high pressure pipe. If the pump is rocked away from the bracket and engine as the 10 mm bolt is loosened eventually the pump will separate from the bracket when it clears 2 guide bushings that pass thru the bracket and into the pump. Even then the stud/bolt shown below prevents the bracket from separating from the engine because of the guide bushings.