2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,562

- Reaction score

- 375

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

There are several threads on the forum describing the idle adjustment process and the following one is very helpful: Idle Air Control Adjustment

There is also the Ford suggested method that is detailed on the LaSota Racing website. Common Idle Issues/Fixes

Below are the stock idle speeds (RPM) for my 2000 SOHC V6 with strategy CDE4.

Idle speed in Neutral (Park) = 656

Idle speed adder with A/C on in Neutral = 0

Idle speed in Drive = 624

Idle speed adder with A/C on in Drive = 0

MPH for idle control = 0 to 2

Idle speed adder for ECT

ECT +RPM

254 . 544

230 . 544

220 . 120

206 .... 0

142 .... 0

100 . 248

<100 248

Idle speed adder for IAT

IAT +RPM

254 .. 48

200 .. 48

190 .... 0

44 ...... 0

34 .... 32

0 .... 232

<0 .. 232

The IAC valve is an electro-mechanical device that is prone to degradation and failure with age. Performing the procedure described below will allow the engine to continue to idle at a reduced engine speed when the IAC valve is no longer functioning correctly. I suggest that you perform the TPS Test Procedure before performing the procedure below.

Your engine should be in reasonably good tune with no vacuum leaks or other problems that would prevent a steady idle.

It is always a good idea to insure the throttle plate does not stick open or closed.

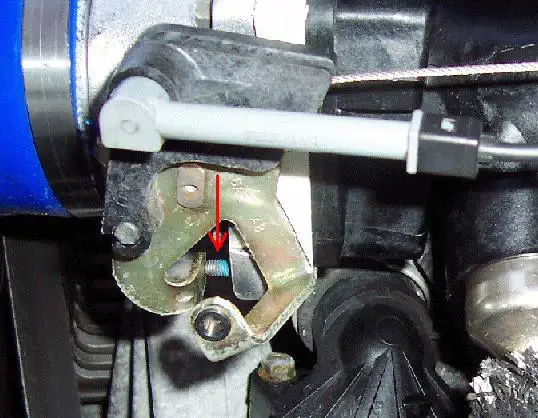

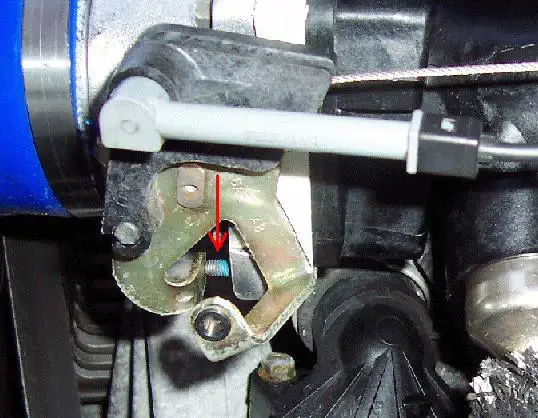

There is no hexagon or slot on the end of the screw that contacts a stop on the throttle body when the throttle plate is closed. Turning the screw opens or closes the throttle plate slightly and acts as a mechanical idle adjustment. The red arrow in the photo below identifies the idle adjustment screw.

Thread lock is applied to the screw to prevent movement due to vibration. I decided to replace the screw with a socket (Allen) head cap screw M5-.80 x 20 that I purchased from Lowe's. I lubricated the original screw with WD-40 and proceeded to remove the screw by grasping one end with ViseGrips and rotating the screw. This was a very tedious and time consuming process because the very restricted work space limited each turn to about 30 degrees. When the task was finally completed I installed the replacement cap screw using an Allen wrench. I applied WD-40 to the new cap screw instead of thread lock because it was a tight fit and I did not want it to break!

The vehicle tachometer is not very accurate so I used my X3 Power Flash in the monitor mode to read rpm, desired_idle_rpm, and coolant_temp (engine coolant temperature). I observed that as the coolant_temp increased the desired_idle_rpm decreased gradually to 736 rpm and rpm decreased to 750 rpm with the transmission in Park and the air conditioner compressor not engaged. I experimented with the idle adjustment and the IAC valve connector and learned that the IAC valve controlled idle speed was approximately 200 rpm greater than the idle speed with the IAC valve electrical connector disconnected. I also noticed that actual rpm was approximately 20 rpm greater than desired_idle_rpm. I believe that Ford suggests for a stock engine to adjust the idle speed to 500 rpm with the IAC valve disconnected. Many engine performance modifications detract from a low speed smooth idle. In my case, 550 rpm was much smoother than 500 rpm and resulted in a 750 rpm IAC valve controlled idle. I do not recommend an IAC valve controlled idle speed greater than 850 rpm for vehicles with an automatic transmission. More than that will increase brake wear and transmission fluid temperature and decrease fuel economy. When I selected Drive from Park, the desired_idle_rpm slowly decreased from 736 rpm to 688 rpm. When I switched on the air conditioner the desired_idle_rpm increased.

My revised version of the Ford procedure is as follows:

1) If you have a stock tune use the information above to determine the PCM desired idle speed. If you have a custom tune get the information from your tuner. If you have a custom tune and don't know the value you can read the parameter with a scanner or data logger. This will be your target idle rpm. You do not want the throttle stop adjustment to conflict with the PCM controlled IAC valve.

2) Start the engine and wait for the engine coolant temperature to reach normal operating temperature as indicated on the instrument panel or by OBD monitor. This will take several minutes or longer if a cold start.

3) Disconnect the IAC valve electrical connector. If the engine stops, turn the throttle-stop screw in one full turn, reconnect the IAC valve electrical connector and restart the engine.

4) Repeat step 3 above until the engine continues to run when the IAC valve electrical connector is disconnected.

5) Turn the throttle stop screw to adjust the idle speed to the target rpm minus 200 rpm.

6) Reconnect the IAC valve electrical connector. The engine speed will briefly flare and then settle. Compare the idle rpm to the target rpm. If satisfactory proceed to step 7. Otherwise, disconnect the IAC valve electrical connector, adjust screw accordingly, then reconnect connector and recompare.

7) Turn the ignition Off.

8) Disconnect the negative terminal of the battery cable from the battery. Turn the headlight switch On for 3 minutes then Off and reconnect the battery. This clears stored idle settings and fuel trims.

9) Start the engine and observe the idle speed in Park and in Drive. If satisfactory be comfortable knowing that in the future should the IAC valve fail, the engine will continue to idle but at a lower rpm. If unsatisfactory, disconnect the IAC valve electrical connector, adjust the throttle stop screw as desired and return to step 6.

Notes:

The PCM determines when the engine is at idle by measuring the TPS value when the ignition is switched on and storing it in non-volatile memory. The PCM assumes that the accelerator will not be depressed when switching on the ignition. The PCM periodically checks for a lower TPS value and if one is observed stores that as an updated idle value.

When vehicle speed exceeds 2 MPH (stock tune) and throttle plate is closed PCM will be in dashpot mode instead of idle speed control.

If the brake pedal position switch (BPPS) is not functional the PCM will not unlock the torque converter when the vehicle is stopped and the engine will likely stall.

There is also the Ford suggested method that is detailed on the LaSota Racing website. Common Idle Issues/Fixes

Below are the stock idle speeds (RPM) for my 2000 SOHC V6 with strategy CDE4.

Idle speed in Neutral (Park) = 656

Idle speed adder with A/C on in Neutral = 0

Idle speed in Drive = 624

Idle speed adder with A/C on in Drive = 0

MPH for idle control = 0 to 2

Idle speed adder for ECT

ECT +RPM

254 . 544

230 . 544

220 . 120

206 .... 0

142 .... 0

100 . 248

<100 248

Idle speed adder for IAT

IAT +RPM

254 .. 48

200 .. 48

190 .... 0

44 ...... 0

34 .... 32

0 .... 232

<0 .. 232

The IAC valve is an electro-mechanical device that is prone to degradation and failure with age. Performing the procedure described below will allow the engine to continue to idle at a reduced engine speed when the IAC valve is no longer functioning correctly. I suggest that you perform the TPS Test Procedure before performing the procedure below.

Your engine should be in reasonably good tune with no vacuum leaks or other problems that would prevent a steady idle.

It is always a good idea to insure the throttle plate does not stick open or closed.

There is no hexagon or slot on the end of the screw that contacts a stop on the throttle body when the throttle plate is closed. Turning the screw opens or closes the throttle plate slightly and acts as a mechanical idle adjustment. The red arrow in the photo below identifies the idle adjustment screw.

Thread lock is applied to the screw to prevent movement due to vibration. I decided to replace the screw with a socket (Allen) head cap screw M5-.80 x 20 that I purchased from Lowe's. I lubricated the original screw with WD-40 and proceeded to remove the screw by grasping one end with ViseGrips and rotating the screw. This was a very tedious and time consuming process because the very restricted work space limited each turn to about 30 degrees. When the task was finally completed I installed the replacement cap screw using an Allen wrench. I applied WD-40 to the new cap screw instead of thread lock because it was a tight fit and I did not want it to break!

The vehicle tachometer is not very accurate so I used my X3 Power Flash in the monitor mode to read rpm, desired_idle_rpm, and coolant_temp (engine coolant temperature). I observed that as the coolant_temp increased the desired_idle_rpm decreased gradually to 736 rpm and rpm decreased to 750 rpm with the transmission in Park and the air conditioner compressor not engaged. I experimented with the idle adjustment and the IAC valve connector and learned that the IAC valve controlled idle speed was approximately 200 rpm greater than the idle speed with the IAC valve electrical connector disconnected. I also noticed that actual rpm was approximately 20 rpm greater than desired_idle_rpm. I believe that Ford suggests for a stock engine to adjust the idle speed to 500 rpm with the IAC valve disconnected. Many engine performance modifications detract from a low speed smooth idle. In my case, 550 rpm was much smoother than 500 rpm and resulted in a 750 rpm IAC valve controlled idle. I do not recommend an IAC valve controlled idle speed greater than 850 rpm for vehicles with an automatic transmission. More than that will increase brake wear and transmission fluid temperature and decrease fuel economy. When I selected Drive from Park, the desired_idle_rpm slowly decreased from 736 rpm to 688 rpm. When I switched on the air conditioner the desired_idle_rpm increased.

My revised version of the Ford procedure is as follows:

1) If you have a stock tune use the information above to determine the PCM desired idle speed. If you have a custom tune get the information from your tuner. If you have a custom tune and don't know the value you can read the parameter with a scanner or data logger. This will be your target idle rpm. You do not want the throttle stop adjustment to conflict with the PCM controlled IAC valve.

2) Start the engine and wait for the engine coolant temperature to reach normal operating temperature as indicated on the instrument panel or by OBD monitor. This will take several minutes or longer if a cold start.

3) Disconnect the IAC valve electrical connector. If the engine stops, turn the throttle-stop screw in one full turn, reconnect the IAC valve electrical connector and restart the engine.

4) Repeat step 3 above until the engine continues to run when the IAC valve electrical connector is disconnected.

5) Turn the throttle stop screw to adjust the idle speed to the target rpm minus 200 rpm.

6) Reconnect the IAC valve electrical connector. The engine speed will briefly flare and then settle. Compare the idle rpm to the target rpm. If satisfactory proceed to step 7. Otherwise, disconnect the IAC valve electrical connector, adjust screw accordingly, then reconnect connector and recompare.

7) Turn the ignition Off.

8) Disconnect the negative terminal of the battery cable from the battery. Turn the headlight switch On for 3 minutes then Off and reconnect the battery. This clears stored idle settings and fuel trims.

9) Start the engine and observe the idle speed in Park and in Drive. If satisfactory be comfortable knowing that in the future should the IAC valve fail, the engine will continue to idle but at a lower rpm. If unsatisfactory, disconnect the IAC valve electrical connector, adjust the throttle stop screw as desired and return to step 6.

Notes:

The PCM determines when the engine is at idle by measuring the TPS value when the ignition is switched on and storing it in non-volatile memory. The PCM assumes that the accelerator will not be depressed when switching on the ignition. The PCM periodically checks for a lower TPS value and if one is observed stores that as an updated idle value.

When vehicle speed exceeds 2 MPH (stock tune) and throttle plate is closed PCM will be in dashpot mode instead of idle speed control.

If the brake pedal position switch (BPPS) is not functional the PCM will not unlock the torque converter when the vehicle is stopped and the engine will likely stall.