MuscleJunkie

Elite Explorer

- Joined

- April 14, 2007

- Messages

- 1,028

- Reaction score

- 352

- Year, Model & Trim Level

- '00 Ford Explorer LTD AWD

Ok, I have an update and a couple conclusions. Also curious to hear any addition input/thoughts about it

As I previously posted, we made some effort to address potential belt slip I was experiencing with my 2.7/6.5 pulley combo (The Powerdyne XB-1a has a 3.44 gearbox ratio). It seems that this effort paid off and we saw some big torque increases through the rpm range. FYI, it’s estimated the 2000 Explorer with 302 5.0 Liter Windsor V8 has a driveline loss of 25% or more because of the 4R70W automatic transmission and Borg Warner 4405 AWD system. Add this to these numbers if you want to know the crank hp/torque numbers.

It also appears that the tune needs to be adjusted because it appears to sharply pull engine timing (???) at 4500rpm. My understanding is since we are making more power/boost due to reduced belt slip (??) the previous very safe tune can be adjusted and we will ultimately see these new gains continue up through past 4500 rpm instead of the current drop due to pulled timing. Shop estimates an additional gain of perhaps 25 hp or more after 4500

Here are two Dyno sheets

The 1st shows a comparison between last high Dyno run on October 9 before fixing the belt slip problem (ORANGE) and October 30 (GREEN) after the effort to fix it. You can see the gains in the lower and mid rpm range

There was some question about how much boost is being lost by the WTA intercooler. The second Dyno sheets show the last two runs on October 30. If you see the bottom graph on that sheet, you can see the pre-intercooler boost pressure (GREEN) and post-intercooler (RED).

We are only seeing a peak of 0.11lbs of boost loss due to the intercooler.

So some conclusions and next steps??

* It appears we had some success in reducing belt slip with the 2.7/6.5 pulley combo

* Previous very safe tune needs to be adjusted as it seems to be pulling timing at around 4500 rpm

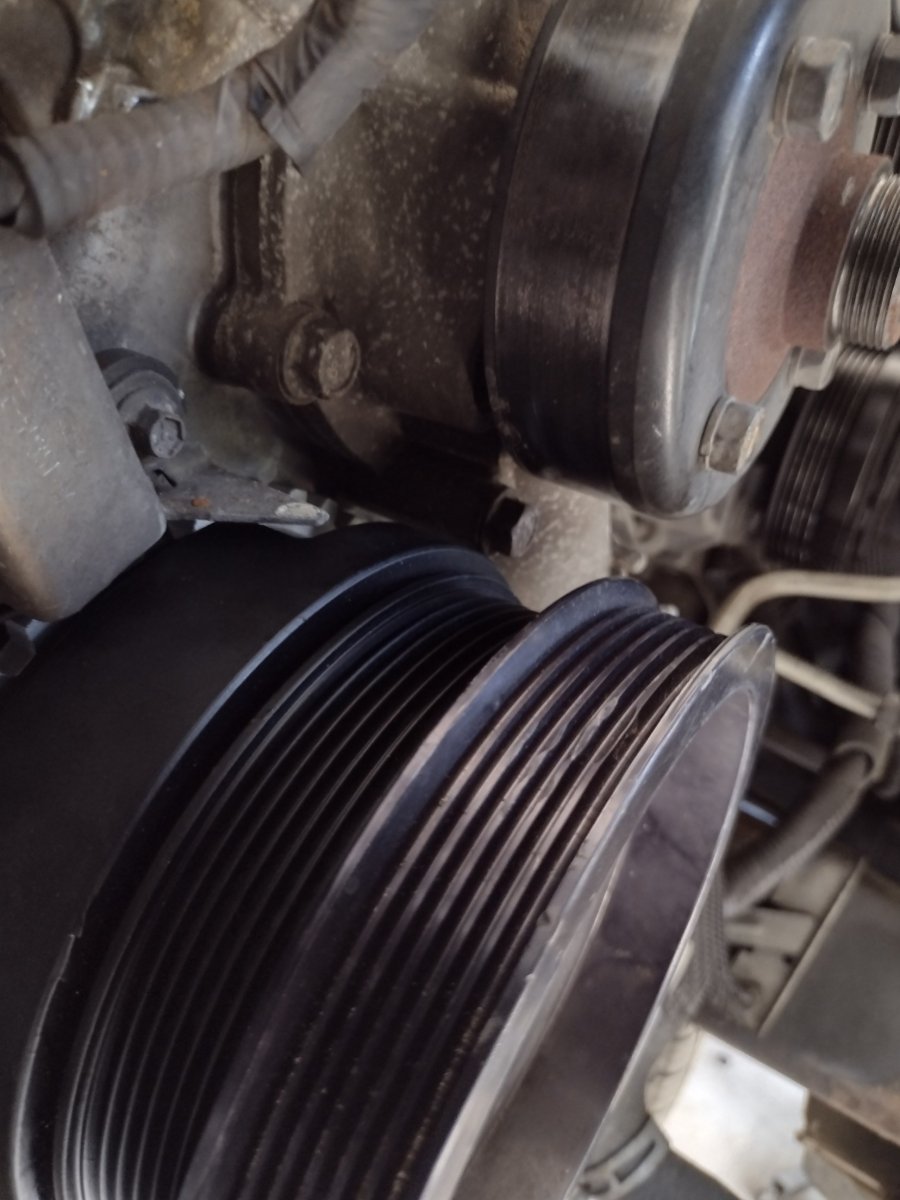

* Need to find a way to install a bigger crank pulley The current 2.7/6.5 pulley is now only spinning the blower in to 40k rpm range. I’m told this blower is “pesky” and sees bigger gains at higher rpm’s when compared to the BD-11a. Right now the water pump pulley on the Explorer prevents me from installing a bigger supercharger crankshaft pulley (see last photo). I am no longer driving a fan off the water pump since going to an efan solution. The Explorer 302 uses a much shorter front dress(???) that the Mustang 302 so I might need to find a custom solution to solve this issue. A bigger crank pulley will allow me to spin the blower faster with reduced chances of belt slip which should result in even more HP and torque gains on this combo.

instagram.com

instagram.com

As I previously posted, we made some effort to address potential belt slip I was experiencing with my 2.7/6.5 pulley combo (The Powerdyne XB-1a has a 3.44 gearbox ratio). It seems that this effort paid off and we saw some big torque increases through the rpm range. FYI, it’s estimated the 2000 Explorer with 302 5.0 Liter Windsor V8 has a driveline loss of 25% or more because of the 4R70W automatic transmission and Borg Warner 4405 AWD system. Add this to these numbers if you want to know the crank hp/torque numbers.

It also appears that the tune needs to be adjusted because it appears to sharply pull engine timing (???) at 4500rpm. My understanding is since we are making more power/boost due to reduced belt slip (??) the previous very safe tune can be adjusted and we will ultimately see these new gains continue up through past 4500 rpm instead of the current drop due to pulled timing. Shop estimates an additional gain of perhaps 25 hp or more after 4500

Here are two Dyno sheets

The 1st shows a comparison between last high Dyno run on October 9 before fixing the belt slip problem (ORANGE) and October 30 (GREEN) after the effort to fix it. You can see the gains in the lower and mid rpm range

There was some question about how much boost is being lost by the WTA intercooler. The second Dyno sheets show the last two runs on October 30. If you see the bottom graph on that sheet, you can see the pre-intercooler boost pressure (GREEN) and post-intercooler (RED).

We are only seeing a peak of 0.11lbs of boost loss due to the intercooler.

So some conclusions and next steps??

* It appears we had some success in reducing belt slip with the 2.7/6.5 pulley combo

* Previous very safe tune needs to be adjusted as it seems to be pulling timing at around 4500 rpm

* Need to find a way to install a bigger crank pulley The current 2.7/6.5 pulley is now only spinning the blower in to 40k rpm range. I’m told this blower is “pesky” and sees bigger gains at higher rpm’s when compared to the BD-11a. Right now the water pump pulley on the Explorer prevents me from installing a bigger supercharger crankshaft pulley (see last photo). I am no longer driving a fan off the water pump since going to an efan solution. The Explorer 302 uses a much shorter front dress(???) that the Mustang 302 so I might need to find a custom solution to solve this issue. A bigger crank pulley will allow me to spin the blower faster with reduced chances of belt slip which should result in even more HP and torque gains on this combo.

Login • Instagram

Welcome back to Instagram. Sign in to check out what your friends, family & interests have been capturing & sharing around the world.

instagram.com

instagram.com