Well now that Im Elite i figured Id start a thread to document my SAS build...

-

Performance Upgrades - Maintenance - Modifications - Problem Solving - Off-Road - Street Trucks.

Covering the Explorer, ST, Sport, Lincoln Aviator, Sport Trac,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Aerostar.

Featuring H.I. - Human Intelligence.

Register Today It's free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Black Pearl SAS and build

- Thread starter KurtECV

- Start date

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

Finally got around to getting the Zip Locker installed.

Never ever happens, but I got a good patter and backlash within spec on the first try! 6-8 thousands backlash

And scored a set of drive slugs as well, thanks to Gman for picking them up for me.

Never ever happens, but I got a good patter and backlash within spec on the first try! 6-8 thousands backlash

And scored a set of drive slugs as well, thanks to Gman for picking them up for me.

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

Down to the freakin wire for moab!

Truck is almost done.

Gman built me a kick a$$ storage box, being a mechanic I had to have a cool toolbox so I added a tray with Kaizen foam and burned the essential tools into it with room to spare.

25 pound lift struts to assist lifting the tray, the yellow mats (8 total) are absorbent mats for fluid spills and cleanup.

Got the 250 psi viair tank hooked up to the york, 80on/120off with a 140 pop off valve.

Got the york 210 looked up and plumbed. With time running out for moab, getting it wired to the dash is not a priority so the red alligator clips are just going to run the compressor clutch for now. I dont plan on keeping the tank full while wheeling so it is good enough for now.

Thus setup will fill a 35x12.50 tire from 0-30 in 2.5 min at idle. It will do 8+cfm off idle (with a working speed of 6k rpm)

Got the compressor for the Yukon zip locker (off brand pump) wired up, just need to mount the switch on the console.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

It's been a minute since I have updated this thread!

I did lower the truck about 5 inches or so by going back to spring under, dropped the front coil brackets to match.

Added a 8x1.5 PSC ram for steering assist

And added 37s

I did lower the truck about 5 inches or so by going back to spring under, dropped the front coil brackets to match.

Added a 8x1.5 PSC ram for steering assist

And added 37s

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

And the best is yet to come!!!!

I've been waiting since before COVID to buy this next mod, COVID hit this area and I was $50 short from ordering this and held off, my wife ended up getting laid off and we needed the extra money to cover bills but I had to good luck/right place at the right time and was able to buy a NorthWest Fab Ecobox-205.

Some basic measurements, it is looking like I will not have to make any rear driveshaft modifications as the np241 is 18.50" long and the EcoBox/np205 is 19.00"

Going with flange yokes front and rear, which I haven't bought yet so that will be the determining factor if the rear driveshaft is going to work without needing modifications.

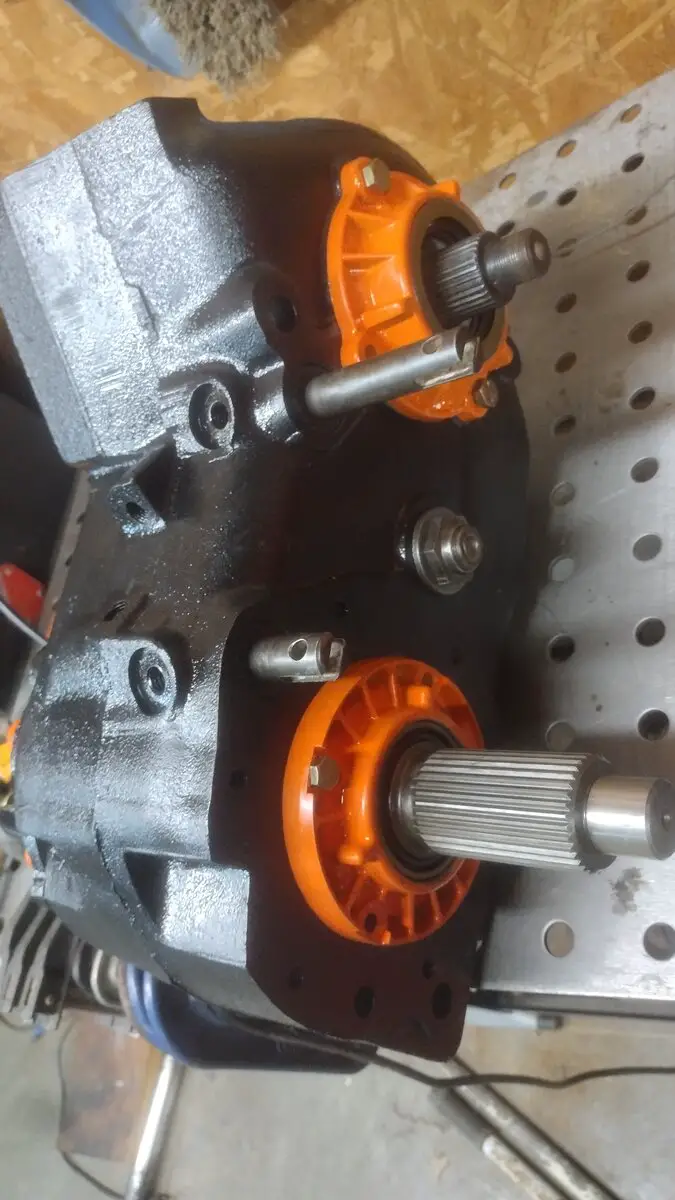

Went ahead and modified the 205 short shift rail for twin stick operation. This will give me the ability to run the front and rear axles independently for 2 wheel drive and 4 wheel drive high and low. Having the front axle engaged and the rear in neutral I will have front digs available in high, low. The doubler will be available for 2.72 gear reduction in any of those configurations

I've been waiting since before COVID to buy this next mod, COVID hit this area and I was $50 short from ordering this and held off, my wife ended up getting laid off and we needed the extra money to cover bills but I had to good luck/right place at the right time and was able to buy a NorthWest Fab Ecobox-205.

Some basic measurements, it is looking like I will not have to make any rear driveshaft modifications as the np241 is 18.50" long and the EcoBox/np205 is 19.00"

Going with flange yokes front and rear, which I haven't bought yet so that will be the determining factor if the rear driveshaft is going to work without needing modifications.

Went ahead and modified the 205 short shift rail for twin stick operation. This will give me the ability to run the front and rear axles independently for 2 wheel drive and 4 wheel drive high and low. Having the front axle engaged and the rear in neutral I will have front digs available in high, low. The doubler will be available for 2.72 gear reduction in any of those configurations

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

I have waited so long for this and am so damn excited. It's like Christmas around the shop

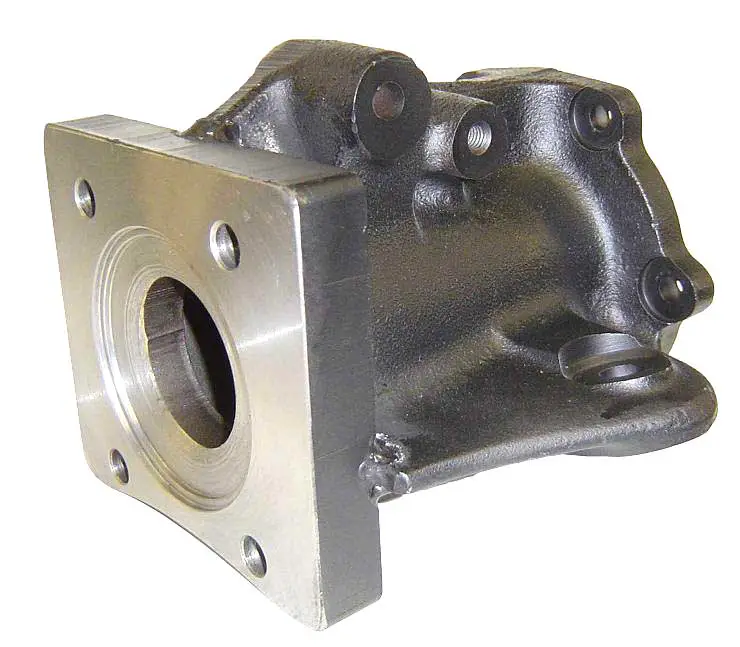

The NorthWest Fab EcoBox-205. Beefed up 32 spline input shaft to match the th400.

Truck is already equipped with the bracket for the triple stick cable shifters (currently only one cable and stick is installed to operate the np241 that is bolted in).

Currently have:

HI/LO/Dbl-Lo Range Rear only

HI/LO/Dbl-Lo Range front only

4-HI/4-LO/4-Dbl-Lo

Doubler is 2.71:1

205 is 1.98:1

Double Low is 5.33:1

Anyone have any ideas for cable brackets at the transfer case? NWF, WOD, ECT only list the entire kit so that may be a phone call away but I am interested to see what others have done.

The NorthWest Fab EcoBox-205. Beefed up 32 spline input shaft to match the th400.

Truck is already equipped with the bracket for the triple stick cable shifters (currently only one cable and stick is installed to operate the np241 that is bolted in).

Currently have:

HI/LO/Dbl-Lo Range Rear only

HI/LO/Dbl-Lo Range front only

4-HI/4-LO/4-Dbl-Lo

Doubler is 2.71:1

205 is 1.98:1

Double Low is 5.33:1

Anyone have any ideas for cable brackets at the transfer case? NWF, WOD, ECT only list the entire kit so that may be a phone call away but I am interested to see what others have done.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

The are both 32 spline and after some digging on the interwebs some versions of the 205s used slip yokes and those cross reference to the same yokes.

Armed with the knowledge I hacked off a few inches of the slip yoke in the bandsaw and beveled the end to 60°, same at the factory fixed yoke the 205 came with.

Now the only kicker here is getting the correct $6 seal (3.0 OD, 1.88 ID). Again this is the factory seal for the output for the 241

- Joined

- November 29, 2000

- Messages

- 10,142

- Reaction score

- 4,113

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

I recently replaced the front yoke on my Atlas II. Advanced Adaptors (AA) builds the case with a silicone washer/seal. AA told me I would not be able to source that seal locally, but any type of oil resistant RTV would work just fine. Little bit on the splines and around the end of the splines before installing the nut. Doesn't seem to be leaking.

My next big purchase for the Explorer after Radflo rear shocks and air bumps is a NWF iBox. Only adds 4" to the length.

Atlas 3.8

Doubler 2.71

Both 10.298

My next big purchase for the Explorer after Radflo rear shocks and air bumps is a NWF iBox. Only adds 4" to the length.

Atlas 3.8

Doubler 2.71

Both 10.298

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

As far as I know the 205 and atlas share the same yokes for the 32 spline outputs. There is a little star rubber washer that slides into the splines before the nut.I recently replaced the front yoke on my Atlas II. Advanced Adaptors (AA) builds the case with a silicone washer/seal. AA told me I would not be able to source that seal locally, but any type of oil resistant RTV would work just fine. Little bit on the splines and around the end of the splines before installing the nut. Doesn't seem to be leaking.

My next big purchase for the Explorer after Radflo rear shocks and air bumps is a NWF iBox. Only adds 4" to the length.

Atlas 3.8

Doubler 2.71

Both 10.298

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

Now that's awesome. Clocked the 205 up one space and it's within the frame.

Nothing like being able to bolt in driveshafts. This is a stock 2002 f350 Diesel front driveshaft. On the 241 I had cut 3 inches or so off of one of these shafts and used it. They are 1350 joints, double carden and thick walled from the factory.

Doing some rough measurements on the front shafts it is extremely likely that I will be able to use equal length driveshafts... The Dana 44 yoke will need to be upgraded from 1310 to 1350 but being able to only carry one spare driveshaft and using a factory f250/f350 shaft means they are plentiful and cheap and can be purchased at a local auto parts store if needed

Nothing like being able to bolt in driveshafts. This is a stock 2002 f350 Diesel front driveshaft. On the 241 I had cut 3 inches or so off of one of these shafts and used it. They are 1350 joints, double carden and thick walled from the factory.

Doing some rough measurements on the front shafts it is extremely likely that I will be able to use equal length driveshafts... The Dana 44 yoke will need to be upgraded from 1310 to 1350 but being able to only carry one spare driveshaft and using a factory f250/f350 shaft means they are plentiful and cheap and can be purchased at a local auto parts store if needed

- Joined

- November 29, 2000

- Messages

- 10,142

- Reaction score

- 4,113

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

They do. Atlas likes to make it sound like their stuff is proprietary when you talk to them, but after I installed the front yoke using some RTV, I did a search and those seals are common and very inexpensive.As far as I know the 205 and atlas share the same yokes for the 32 spline outputs. There is a little star rubber washer that slides into the splines before the nut.

I really like the idea of equal length driveshafts, and a beefy upgrade. If they are a common part, I don't know if I would bother with a spare.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

Yup that shaft that is installed on the rear in the picture is a 100% factory front shaft from an f350. Special order from my auto parts store but only like a day or two outThey do. Atlas likes to make it sound like their stuff is proprietary when you talk to them, but after I installed the front yoke using some RTV, I did a search and those seals are common and very inexpensive.

I really like the idea of equal length driveshafts, and a beefy upgrade. If they are a common part, I don't know if I would bother with a spare.

- Joined

- November 1, 2017

- Messages

- 760

- Reaction score

- 408

- City, State

- Lebanon MO

- Year, Model & Trim Level

- 93 Sport

And one of the final pieces of the puzzle:

1350, 32 spline companion flanges. They are the correct 2" pilot for Ford's.

The bolt pattern matches the 99-06 Ford F350 front driveshafts, which are 1350 CVs.

These companion flanges, and an upgraded 1350 Dana 44 front yoke will be the determining factor whether I can use equal length front and rear driveshafts.

The companion flange upgrades require a specific (but common) output shaft seal.

My local auto parts stores didn't have the specific Timken brand in stock but using the 2.125 ID and 3.062 OD posted above narrows the seals to in-stock National seals

1350, 32 spline companion flanges. They are the correct 2" pilot for Ford's.

The bolt pattern matches the 99-06 Ford F350 front driveshafts, which are 1350 CVs.

These companion flanges, and an upgraded 1350 Dana 44 front yoke will be the determining factor whether I can use equal length front and rear driveshafts.

The companion flange upgrades require a specific (but common) output shaft seal.

My local auto parts stores didn't have the specific Timken brand in stock but using the 2.125 ID and 3.062 OD posted above narrows the seals to in-stock National seals

Similar Threads

- Article

- Replies

- 216

- Views

- 34,062