One thing with FOA, I only have experience with the bumpstops so this is a little bit of 2nd hand info. I've heard they have issues with leaking. (my bumps did) but everyone I've talked to says simply pulling them apart, cleaning them thoroughly and slapping them back together usually fixes it. And... If it doesn't their customer support is GREAT and they'll fix issues no questions asked from the sounds of it and will go out of their way to make sure the customer is taken care of. To me, they sound like their one of those companies that knows they're not perfect, they're trying to make improvements, and till they do, they'll go out of their way to work with the customer to make sure everything is right in the long run. I guess it's just part of the fun of a cheaper entry level type product. Personally for most applications they seem like the perfect shock! Cheaper prices but still fully serviceable and adjustable.

And yeah, you can mix and match shims all day long. You don't have to run just a straight same thickness pack. You can double them up, leave some out, etc...

I guess while I'm here typing and since I was enlightened about the "centering" option on the forum...

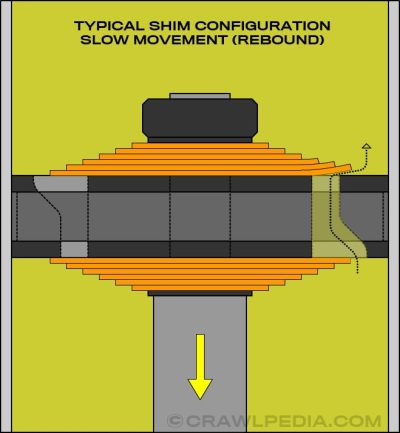

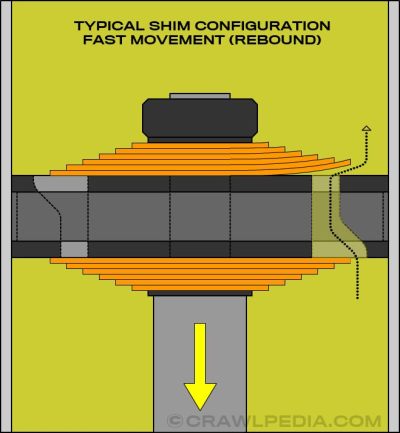

Both of these next ideas are on the compression side. I never really see people doing exotic stuff on the rebound other then sometimes mixing and matching shim thicknesses but they're normally just a straight pyramid stack of shims.

"Flutter stack" is what I normally see this called on the compression side.

-------------------------

-----

------------------

--------------

----------

-------

----

Your piston would be on top since this is the compression stack. the compression stack is the stack on what I guess I'd call the bottom. What this is doing is allowing for a tiny gap for that first shim to flex around. This allows for a soft ride on minor shaft movements. That first shim flexes super easily but on a hard hit it would flex enough to get into the rest of the pack and then become stiffer. I usually see people using like a .010 or .012 shim that is one of the smaller diameter's offered. It's kind of a poor man's bypass shock. Sometimes some will do something like this which is the same effect, only a bit stiffer on the softer portion.

--------------------

---------------

----

-----------

-------

----

The number of shims may be more, may be less... Just showing the concept.

The last set of shocks I did on one of my play trucks though, I used a "rate plate" which is simply a THICK like 1/4" disc. I literally made my own out of some steel plate and a hole saw. It's got to be small enough to fit inside the shock obviously but large enough on the OD that it's bigger then the largest shim on the compression. What a "rate plate" does is almost works as a valving limiter or like a limit strap for your valving. On the last shock I did on my truck I did something like this.

---------------------

------------

-------

----

==========================

Literally I only had 4 shims that were .020 thick and then the 1/4" thick plate. This basically kept me fairly soft on most stuff but then on a really hard hit where the shims would want to drastically flex open, they couldn't. They would flex till they hit that super thick plate and that's it. That's all the oil flow that would be allowed so basically the shock would be soft and then it would instantly spike to a super hard rate and no matter how much that shaft wanted to be shoved into the shock, it couldn't. Now you are creating a hydraulic bind of sort doing this so you need to make sure you're mounts and everything are up to handling the spiked forces this will cause but I was VERY happy with it.

Step further... I've seen people doing a combo of a flutter stack and a rate plate which is actually almost giving them 3 valving rates all within one shim stack. Start mixing in different thicknesses and you different diameters and you can see the possibilities get virtually endless.

Something like this...

-------------------------------

------

------------------------

--------------------

-------

-----

=========================

Let's say the thicknesses were all the same. The largest shim would provide a super soft ride till it got into the shims 3 and 4 counting from top to bottom. Then the rate would increase. But then notice I jump to a drastically smaller diameter on shims 5 and 6? That's allowing for a easy fulcrum for shims 3 & 4 to bend around so they're still fairly soft until the rate plate kicks in and limits the whole thing. The bigger the gap till the rate plate limits it, the softer it will be till that point.

Then start mixing in different shim thicknesses to the pack and well... We're already talking shock black magic and you're really getting crazy at that stage.

really though, once you have one apart. Look at the piston and how the shims cover the oil ports and you'll see how basic the whole concept is. All this will probably make some sense and then it's just a matter of coming up with what may work best for you. You'll be amazed if you really get into it what you can make your explorer do. Like probably mind blowing type stuff where you can flex it great, you can jump it, you can run fast thru moderate bumps and still drive on the street just fine. Really it's all how much effort you want to spend in the trial and error. When you're paying someone to do your shock tuning, you're just paying for their time learning with that trial and error in their previous experience getting to where they are now.

LOL, that should be enough to fry most people's brains!