-

Ford Explorer Community - Maintenance - Modifications - Performance Upgrades - Problem Solving - Off-Road - Street

Explorer Forum Covers the Explorer ST, Explorer Sport, Explorer Sport Trac, Lincoln Aviator,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Ford Aerostar

Register Today It's free!

into

-

D

Hard to shift into gear!

I have a 97' Explorer XLT Control Trac 4WD 4.0 v6 M5R1 5 speed tranny.... I think..... Here's the number on the trans: F57A-FA I've mentioned the hard shifting issue in at least one of my other threads.... Thought I'd open another thread to focus on just this issue! The issue being that it's...- DAZ97XLT

- Thread

- gear hard into shift to

- Replies: 6

- Forum: Transmissions & Transfer Cases

-

The spring has to go into the hole in the bracket.

This is a sliding door latch modification to prevent it from jamming.- BrooklynBay

- Media item

- bracket. go has hole in into spring the to

- Comments: 0

- Category: General Photo Album

-

A floor jack pushes the shock into place.

- BrooklynBay

- Media item

- a floor into jack place pushes shock the

- Comments: 0

- Category: General Photo Album

-

Water is sprayed into the seams.

- BrooklynBay

- Media item

- into is seams sprayed the water

- Comments: 0

- Category: General Photo Album

-

The hinge fits into the routed door.

- BrooklynBay

- Media item

- door fits hinge into routed the

- Comments: 0

- Category: General Photo Album

-

A wheel nut (lug nut) pulls the stud into position.

- BrooklynBay

- Media item

- (lug a into nut nut) position pulls stud the wheel

- Comments: 0

- Category: General Photo Album

-

The copper lines are inserted into the compressor.

- BrooklynBay

- Media item

- are compressor copper inserted into lines the

- Comments: 0

- Category: General Photo Album

-

4 inch PVC plug converted into a 3.0L rear main seal installation tool.

- BrooklynBay

- Media item

- 3.0l 4 a converted inch installation into main plug pvc rear seal tool

- Comments: 0

- Category: General Photo Album

-

Blender converted into an oscillating spindle sander.

- BrooklynBay

- Media item

- an blender converted into oscillating sander spindle

- Comments: 0

- Category: General Photo Album

-

The new overload relay wired into the compressor.

- BrooklynBay

- Media item

- compressor into new overload relay the wired

- Comments: 0

- Category: General Photo Album

-

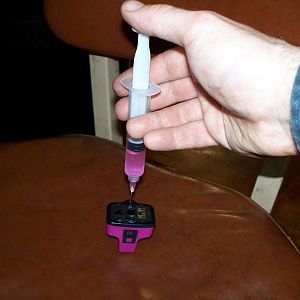

Injecting the ink into the cartridge.

- BrooklynBay

- Media item

- cartridge injecting ink into the

- Comments: 0

- Category: General Photo Album

-

The piston is being pushed back into place.

- BrooklynBay

- Media item

- back being into is piston place pushed the

- Comments: 0

- Category: General Photo Album

-

The caliper pins are going back into place.

- BrooklynBay

- Media item

- are back caliper going into pins place the

- Comments: 0

- Category: General Photo Album

-

Adding differential fluid into the sensor hole.

- BrooklynBay

- Media item

- adding differential fluid hole into sensor the

- Comments: 0

- Category: General Photo Album

-

Inner tube is snapped into place.

- BrooklynBay

- Media item

- inner into is place snapped tube

- Comments: 0

- Category: General Photo Album

-

A4LD valve body end plug with a hole drilled into it for a slap hammer.

This is the end plug from an A4LD which was stuck in the bore. I had to drill a hole in it to attach a slap hammer.- BrooklynBay

- Media item

- a a4ld body drilled end for hammer. hole into it plug slap valve with

- Comments: 0

- Category: General Photo Album

-

Supplies for soldering a drain plug into a pan.

- BrooklynBay

- Media item

- a drain for into pan plug soldering supplies

- Comments: 0

- Category: General Photo Album