Installed new Rear Brake Line

Today, I finally got to replace my rear brake line on my 99 Ford Explorer XL, 4DR, 2WD, 4.0L, OHV, X-Engine.

For the rear brakes, there is only one brake line that runs from the Master Cylinder to the back of the truck alongside the driver’s side in a steel brake line. At the driver’s side rear wheel area, the line converts into a rubber brake hose.

As you can see from this picture, I have to address this connection at some point - Ohio winters have done a number, rust-wise, on the bottom of my Explorer. What is surprising is that the brake line all the way back is perfectly fine and there is not one bit of rust is on it.

---- ---- ---- ---- ---- ----

After the brake line converts to a rubber brake line, it is routed to just behind the rear driver’s side wheel area and splits off. One side goes to the rear driver’s side rear caliper and the other runs over to the passenger side rear caliper.

In this pic below, you can see the rubber brake line coming down and then split off; one side to the driver’s side rear caliper...you can also see my new brake line inserted, where it runs over to the passenger’s side rear caliper.

---- ---- ---- ---- ---- ----

Here is the brake line that I picked up at Advance Auto for about $8 or so. It's 51 inches long and already flared for you. It’s the perfect length – and most importantly, you do NOT have to flare anything. It’s the perfect brake line for this rear brake line repair.

---- ---- ---- ---- ---- ----

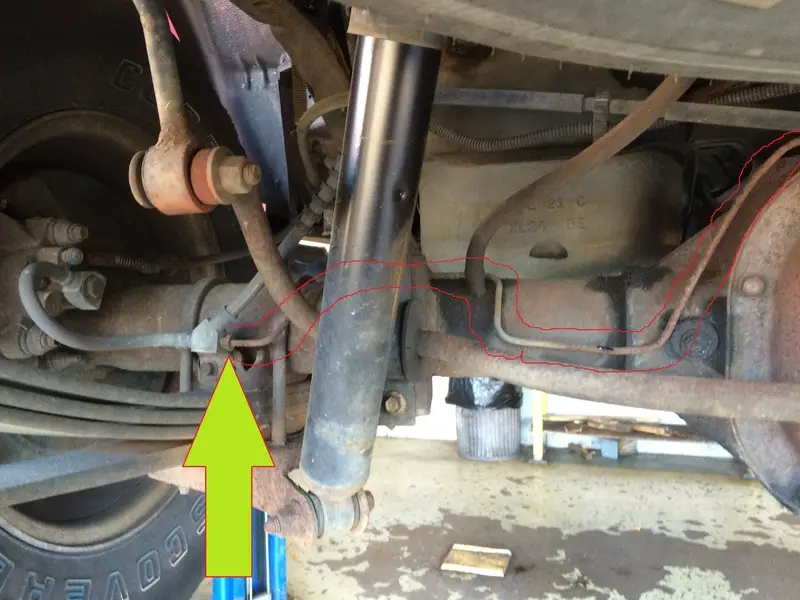

I tried to carefully remove my old brake line using a 3/8 brake line wrench, after spraying the flare nut with plenty with PB Blaster. It was not coming out well, as the old brake line had basically rust-fused itself to the flare nut. The flare nut itself was coming out just fine...it just wanted to hold onto the brake line instead of letting the brake line spin freely around the nut. So, bottom line...you're doing this repair and the old brake line is coming out – so just cut the brake line right at the flare nut - the brake line is just getting in your way. The flare nut turned off just fine once I was not worried about breaking a cancer ridden, rusted brake line, even with all the rust. In this pic below, the arrow points to the flare nut and brake line that I am referring to. The other red lines just indicate the routing of the brake line over the axle.

After I removed the driver’s side flare nut, I did the same thing and removed the passenger side flare nut and removed the old rusted brake line entirely.

---- ---- ---- ---- ---- ----

Now, about the brake line and bending the new straight brake line to match the pattern of the old brake line so that it fits properly around the rear axle...I had a proper brake line bender with me and I tried to use it...but it was just too much of a PITA. So, don’t bother if you don’t have one. A large socket or can will suffice as something to bend the brake line around.

The beauty of the

Poly Armour Brake Line is two-fold. 1st, it bends so easily in your hand - just bend it carefully and nothing beyond 90 degrees unless you are bending it around a spare socket or something else solidly round. Just be careful with it and it will not snap or crack on you. It's flexible and more forgiving than steel brake line I've used in the past. The 2nd benefit is, supposedly there is some coating on it that resists rust from affecting it down the road.

Here's an excerpt from their web page:

…due to its PVF or Poly-Vinyl Fluorine coat. This coating is actually a highly durable ‘plastic’ coating that is ‘baked and cured’ to the line. This provides extra protection from corrosion, debris, and road surfacing solutions. It also offers superior bend-ability without kinking. That makes Poly-Armour the easiest line to work with – period! Underneath the PVF-coating is a double-wall, low carbon steel, copper brazed tubing which meets all international and U.S. requirements for brake tubing. The difference being that Poly-Armour offers 30 times the corrosion resistance of galvanized steel alone.

---- ---- ---- ---- ---- ----

So, I bent the new brake line, trying to follow the contours and bends of the old brake line, side by side. I'll admit, it did not look pretty and I made a few mistakes but I was easily able to re-bend it to get it in the best shape that I could. One NOTE OF WARNING - BEFORE BENDING - Make sure the flare nut is at each flared END before bending - otherwise, you need to unbend it all and start over!

Also, carefully remove the sticker from the brake line so that any pieces of the sticker do not get stuck in the flare nut. Unless you spend a lot of time on the bending, it's not going to be perfect. Don't worry - just get it close to the shape of the old - you can continue the bending/molding the new line after you get it up under the car for install.

---- ---- ---- ---- ---- ----

Before I go on, I wanted to speak about my original concern about this entire thread - that was the rusted clips where the old lines get routed along the axle.

I had pre-treated the rusted clips with PB Blaster and then I carefully pried them up with a screwdriver and they both bent up easily so that I could remove the old brake line from them.

Here are some pics of the new brake line routed through the clips:

---- ---- ---- ---- ---- ----

I put the driver’s side flare nut on first and then tried to better curve the brake line to best fit around the axle and up over the differential to the passenger side. I then put in the passenger side flare nut. I was concerned about the extra and different lengths of the flare nut but it was fine in the end.

---- ---- ---- ---- ---- ----

That's basically it. I had the benefit of a lift to use but not much time - I did this job in a little over two hours (that's probably longer than it should have). If I had to do the job again, I could probably do it in less than 30 minutes, including bleeding the brake line.

About bleeding the brake line; there is only one line that runs from the front to the back. It then splits and routes to each side. I bled the rear passengers side first – actually. I used a large Styrofoam drink cup, filled with some brake fluid, and a larger diameter 3/8 size clear piece of hose that I placed on the end of the bleed valve and then routed the line down through where the straw goes into the cup...down into the brake fluid I poured in the bottom.

I then opened the brake caliper bleed valve and had someone else get in the car and step on the brake 12-15 times slowly while I had the bleed valve open. After they stepped on the brake for 12-15 times I secured the bleed valve and then made sure the brake reservoir at the master cylinder was kept topped off after every 12-15 steps on the brake. I had a quart (32 oz.’s) of new DOT-3 brake fluid on hand. I kept doing this until I had fully clear brake fluid coming out the lines (at least 25 times pumping the brake pedal). I did the same to the driver’s side bleed valve and bleed out any air bubbles.

I was NOT able to bleed the front calipers (and subsequently flush the lines with new fluid). The front bleed valves were frozen into the calipers. I did NOT want to break one at this point. I will take care of the front bleed valves down the road and replace them when I get a chance. Not bleeding the front lines seemed to have no ill effects on properly bleeding the brake system. The vehicles braking systems seems just fine.

Hope some of these pics help others down the road!