Atlas Antipode

Elite Explorer

- Joined

- May 14, 2023

- Messages

- 11

- Reaction score

- 3

- City, State

- Iqaluit

- Year, Model & Trim Level

- 2018 Explorer XLT 3.5 n/a

Good morning everyone. I'm looking for confirmation of the actions I'll be taking to solve the problem described below.

For context, it's a 2018 Ford Explorer XLT 3.5 AWD with about 90,500 kilometres.

The wife came home after work yesterday to tell me that a bunch of lights on the instrument cluster had light up on her way home. I went out to check and sure enough the ABS, Traction and Stability lights were all illuminated. I asked if anything unusual happened to which she replied 'no'.

I grabbed the code scanner, reviewed 6 or so codes and found the most telling one was C003A - right rear abs wheel speed sensor. It was later in the evening, so I could not do a visual inspection until this morning.

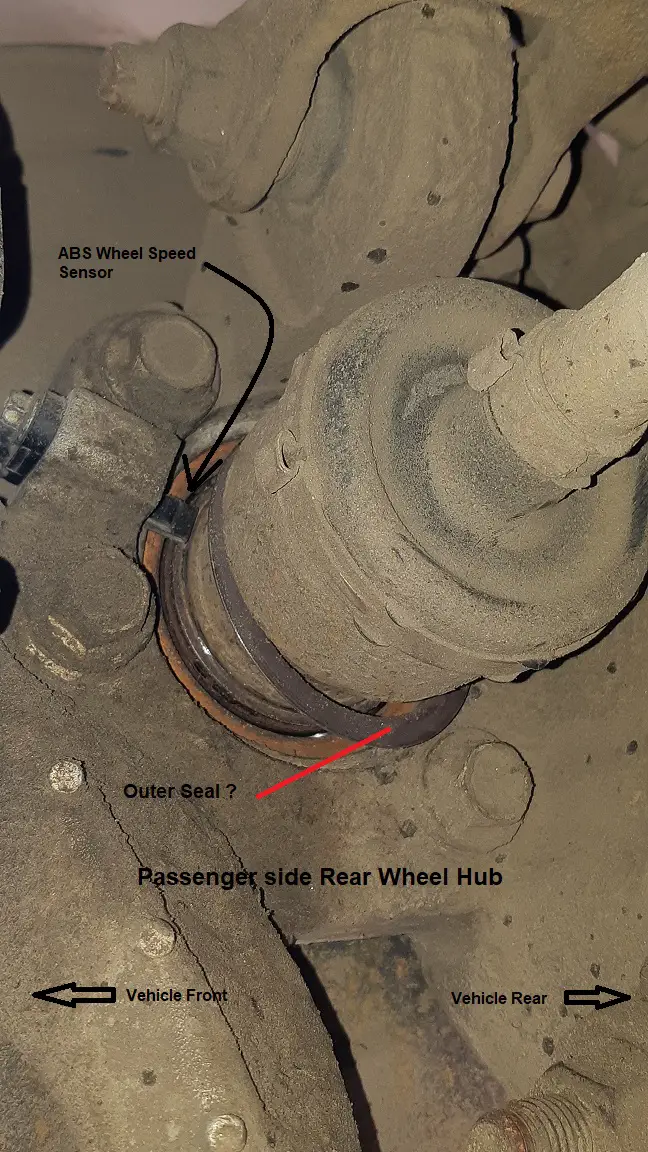

It appears that the right rear wheel speed sensor is slightly bend, the inner seal has split from the hub, and the metal has somehow migrated past the sensor (I did wipe down the sensor prior to taking the photo):

I also found the rubber seal wrapped around the shaft:

Here is a view of the driver's side rear hub for comparison. Aside from the dirt, everything appears okay to me.

I'll wondering if I'll need to replace the entire right rear wheel hub (as in all needed components already come installed on the hub), or if it could be a missing tone ring? I can't determine if there is a tone ring anywhere inside the wheel hub or inside the seal(?) itself, as there is nothing online that tells me that the tone ring is separate part.

Thanks.

For context, it's a 2018 Ford Explorer XLT 3.5 AWD with about 90,500 kilometres.

The wife came home after work yesterday to tell me that a bunch of lights on the instrument cluster had light up on her way home. I went out to check and sure enough the ABS, Traction and Stability lights were all illuminated. I asked if anything unusual happened to which she replied 'no'.

I grabbed the code scanner, reviewed 6 or so codes and found the most telling one was C003A - right rear abs wheel speed sensor. It was later in the evening, so I could not do a visual inspection until this morning.

It appears that the right rear wheel speed sensor is slightly bend, the inner seal has split from the hub, and the metal has somehow migrated past the sensor (I did wipe down the sensor prior to taking the photo):

I also found the rubber seal wrapped around the shaft:

Here is a view of the driver's side rear hub for comparison. Aside from the dirt, everything appears okay to me.

I'll wondering if I'll need to replace the entire right rear wheel hub (as in all needed components already come installed on the hub), or if it could be a missing tone ring? I can't determine if there is a tone ring anywhere inside the wheel hub or inside the seal(?) itself, as there is nothing online that tells me that the tone ring is separate part.

Thanks.