2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,562

- Reaction score

- 376

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

Air filter cover

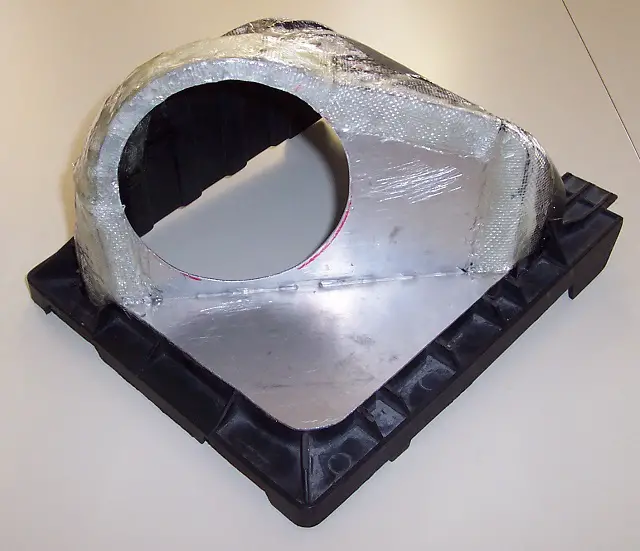

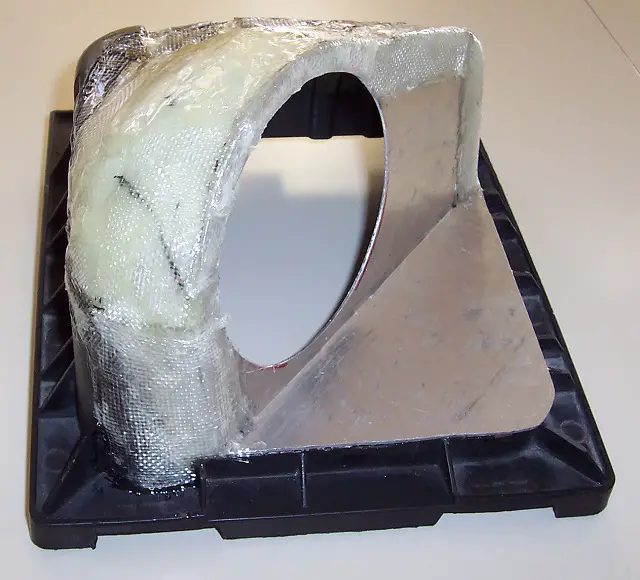

I modified the stock air filter cover by cutting out a large section and then attaching a piece of aluminum with a 100 degree bend and the upper half section of a bleach bottle.

Then I added several layers of fiberglass tape and epoxy left over from a wood boat building project from many years ago.

I applied a couple coats of Fusion for plastic spray paint.

In a year when I clean the reusable Amsoil air filter I may smooth the outside and spray again for better appearance.

I was unable to find a 4 inch diameter friction fit gasket to attach to the cover so I made one out of 3/8" dia. nonporous caulk saver. I cut a length a little shorter than the dia. of the MAF sensor adapter tube. Then I glued the ends together with a short length of 18 gauge, insulated, stranded wire poked in each end to keep the ends centered and together.

I modified the stock air filter cover by cutting out a large section and then attaching a piece of aluminum with a 100 degree bend and the upper half section of a bleach bottle.

Then I added several layers of fiberglass tape and epoxy left over from a wood boat building project from many years ago.

I applied a couple coats of Fusion for plastic spray paint.

In a year when I clean the reusable Amsoil air filter I may smooth the outside and spray again for better appearance.

I was unable to find a 4 inch diameter friction fit gasket to attach to the cover so I made one out of 3/8" dia. nonporous caulk saver. I cut a length a little shorter than the dia. of the MAF sensor adapter tube. Then I glued the ends together with a short length of 18 gauge, insulated, stranded wire poked in each end to keep the ends centered and together.