gottahabet

New Member

- Joined

- May 30, 2018

- Messages

- 5

- Reaction score

- 1

- City, State

- Burbank, CA

- Year, Model & Trim Level

- 1998 Explorer XLT 4 door

Hi everyone,

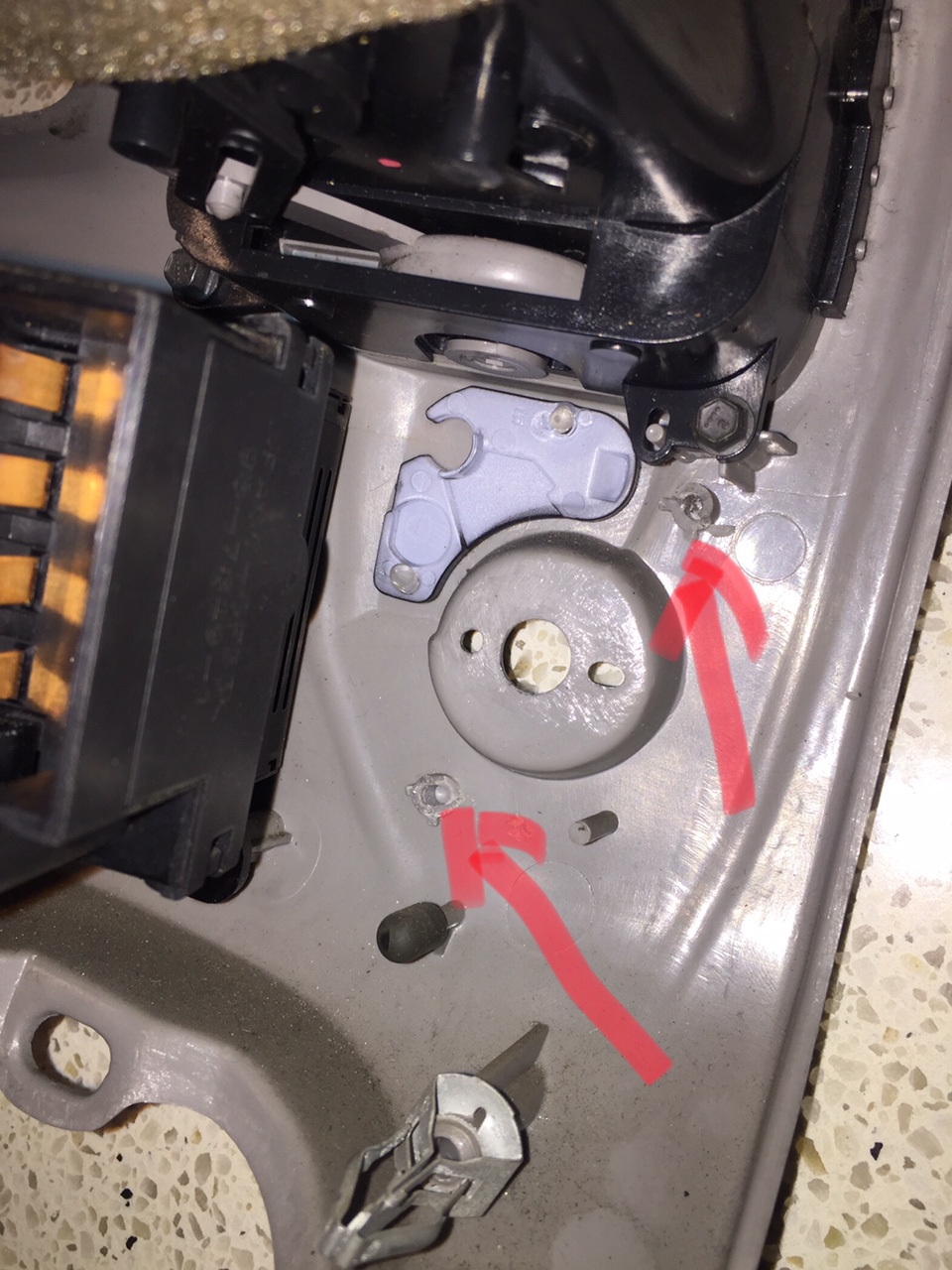

I just joined the forum. I've had a 98 Explorer XLT for about 12 years now (hey, it's paid off). Recently the headlight switch on my instrument panel had begun getting so loose that I could barely operate it. So I found a video on youtube from 1aauto.com and followed the directions for replacing the switch. Upon pulling off the instrument cluster bezel in which the switch and cabin dimmer are housed, I noticed that the business end of the switch, behind the panel, had come off it's screw-in moorings completely. In other words, the switch was still screwed in, but the plastic screw holders had broken off of the panel, rendering them useless (see photo). So now it appears I have to replace the entire bezel/panel just to get around two tiny, bad, plastic screw moorings that snapped off over time. I've looked on ebay motors, and found one in my color/trim, but it's going to be over $70 for a used one.

My question is, has anyone run into this issue, and might there be a work-around for it, like somehow rigging up new moorings using epoxy or something?

I just joined the forum. I've had a 98 Explorer XLT for about 12 years now (hey, it's paid off). Recently the headlight switch on my instrument panel had begun getting so loose that I could barely operate it. So I found a video on youtube from 1aauto.com and followed the directions for replacing the switch. Upon pulling off the instrument cluster bezel in which the switch and cabin dimmer are housed, I noticed that the business end of the switch, behind the panel, had come off it's screw-in moorings completely. In other words, the switch was still screwed in, but the plastic screw holders had broken off of the panel, rendering them useless (see photo). So now it appears I have to replace the entire bezel/panel just to get around two tiny, bad, plastic screw moorings that snapped off over time. I've looked on ebay motors, and found one in my color/trim, but it's going to be over $70 for a used one.

My question is, has anyone run into this issue, and might there be a work-around for it, like somehow rigging up new moorings using epoxy or something?