97Sandbox

Elite Explorer

- Joined

- February 7, 2019

- Messages

- 1,103

- Reaction score

- 998

- City, State

- Seward, NE

- Year, Model & Trim Level

- 2000 Explorer Sport

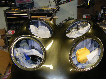

Yeah, mine were garbage so I fixed a rusty set of TMH instead.

I may try again someday if I have a good TIG setup. MIG welds are just too porous to seal reliably and my attempts to seal over the beads were unsuccessful.

I may try again someday if I have a good TIG setup. MIG welds are just too porous to seal reliably and my attempts to seal over the beads were unsuccessful.