LONO100

Explorer Addict

- Joined

- March 23, 2011

- Messages

- 2,897

- Reaction score

- 26

- City, State

- Bay Area CA

- Year, Model & Trim Level

- 03 sport trac XLT

here is my "how to" on installing an aussie locker into a solid axle 8.8 rear differential for the non-mechanic. this was installed into a 2003 sport trac XLT. if there are any mistakes ive made in terminology, or if i left anything out, or if i did something wrong, please feel free to comment and add to this install how to. i didnt know exactly where to post this, so moderators feel free to move it to its correct place. sorry for the bad lighting on some of the video and pics, it was nightfall during part of the install. i hope this write up will help other members take the leap and install a set of lockers but were too afraid to do it. i am moderately mechanically inclined, ive replaced alternators, gaskets, pads and brakes before, but never opened up a diff, so if i can do it, you can most likely do it too if you do enough homework and prep.

PLEASE READ OVER THIS HOW TO AT LEAST ONCE OVER BEFORE YOU START YOUR INSTALL!!!

the best thing you can do if you arent familiar with lockers (like me) is to do a lot of reading on this forum and other websites on what lockers do, and determine if this is something you want in your rig. now that i have them on mine, i love them but that might not be the same for everyone. also do some homework and get familiar with how and why differentials work and what their function is. then the install will be much more easier on you. this install should translate in principle to other lunchbox lockers like the richmond powertrax locker as well.

this is a how to on locker installs for the everyday guy who is moderately mechanically inclined (such as me) but were too intimidated by all of those gears in your diff. post any questions if you have them and good luck on your install!

first things first: the aussie locker model# for the ford 8.8 solid axle open differential is the XD48831.

here are the materials you will need to complete the install:

3 qts. of gear oil, i used 75w140, but other members have told me that they run 85w140 in hotter climates, ultrablack RTV, brake cleaner, bearing grease, feeler gauge, super funnel, carrier pin retaining bolt, WD40, PB blaster, a super funnel or some sort of pump to get the new diff fluid in, two jack stands, a jack, and a buddy if available (just bribe with beer).

no special tools needed for this particular axle, a standard socket set with 3/8 adapter, a set of wrenches with box ends, assorted pliers, a crescent wrench, razor blade, flathead screwdrivers (assorted widths) a rubber mallet, and the thinnest wire coat hanger you can find in your closet (remember, the thinnest you can find!).

try to soak the diff plug, your sway bar bolts, diff cover bolts and all other bolts with the pb blaster the day before you install, it will make everything much easier.

remove the spare tire to give yourself some room under there. if youve never taken off your spare before, use the jack equipment and find the hole under the tailgate and spin that tire down.

block the front wheels with some blocks, or spare wheels or chocks. then release the e brake and put the truck in N, jack the rear end up, and place the jack stands under the axles. i like to put the spare wheel under the truck as well as an insurance policy just in case.

next, you want to remove your sway bar for more room. the easiest way is to

remove the bottom bolts holding your rear shocks, then remove all of the bolts attaching the sway bar to the axle and swaybar arms.

then, find the diff plug and soak it with some PB blaster and use your ratchet adapter (3/8) and see if you can loosen the plug before you can do anything else, but dont pull it off just yet.

next, loosen the diff cover bolts. loosen the top bolt, but dont take it off, once all of but the top bolt are removed, put a drip pan under the diff, use a flathead screwdriver and pry the diff cover from the bottom enough until the fluid starts to drip into the pan.

there is a how to on the forum on changing your diff fluid. it should help if you are still uncomfortable with doing this part.

give it a little while for all the oil to spill out of the diff. that stuff moves like molasses, so be patient.

next, it would be good to clean your diff cover. wipe the residual oil from it, then clean it with some brake cleaner. then use a razor to clean off the old gasket or RTV silicone.

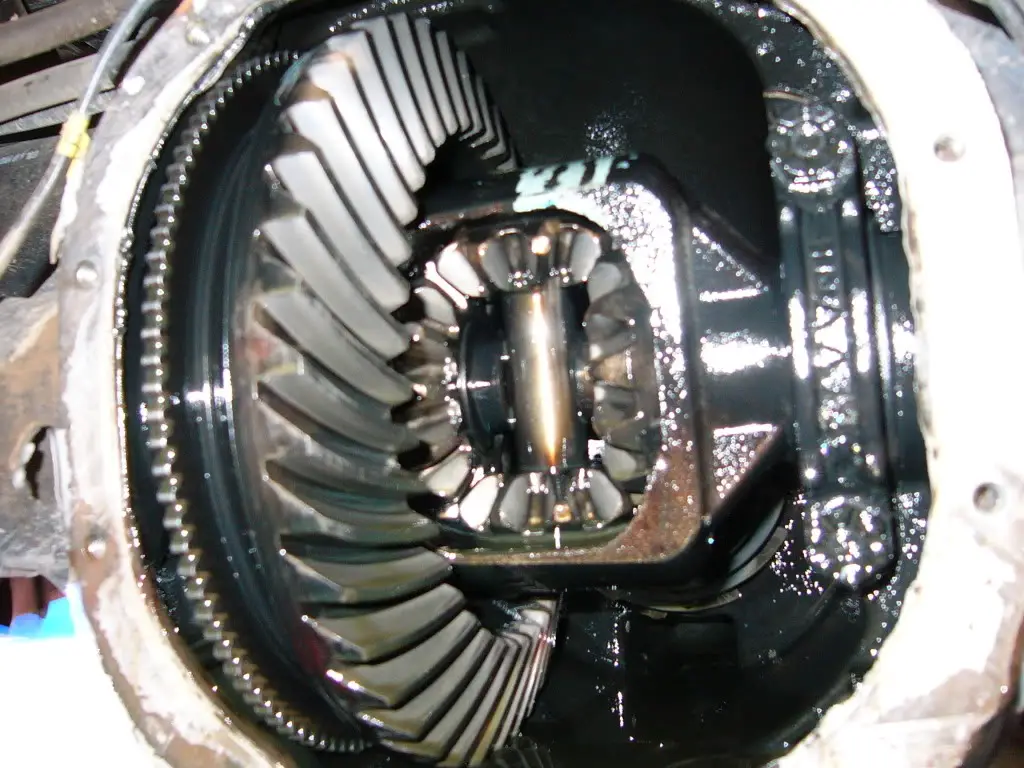

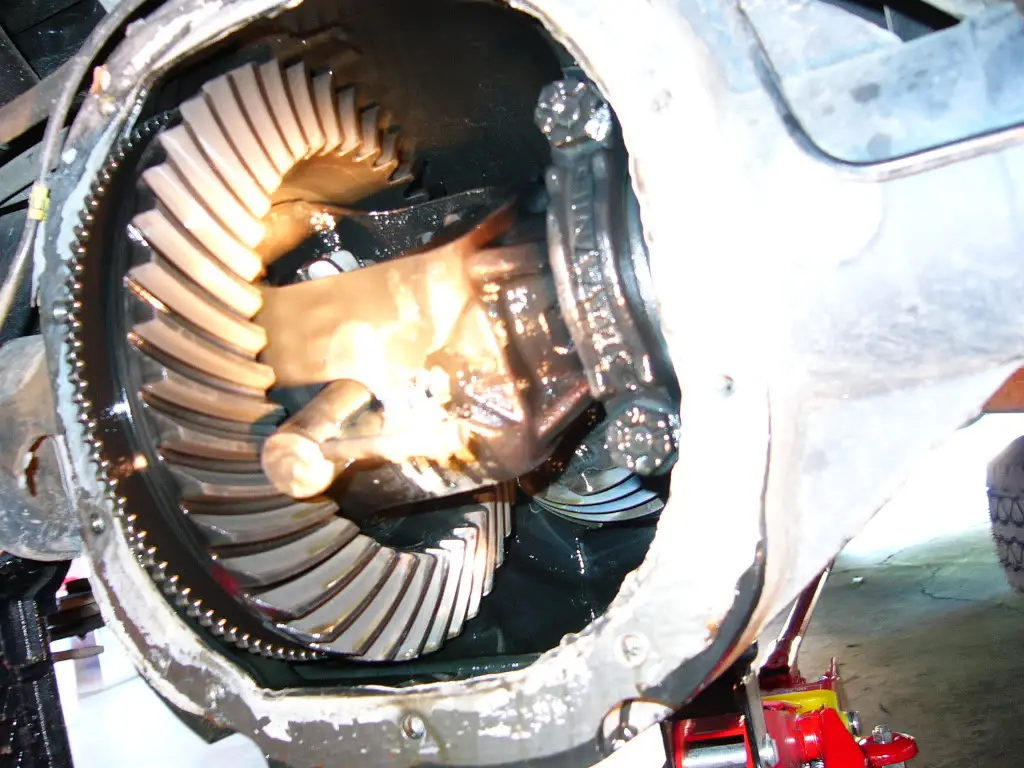

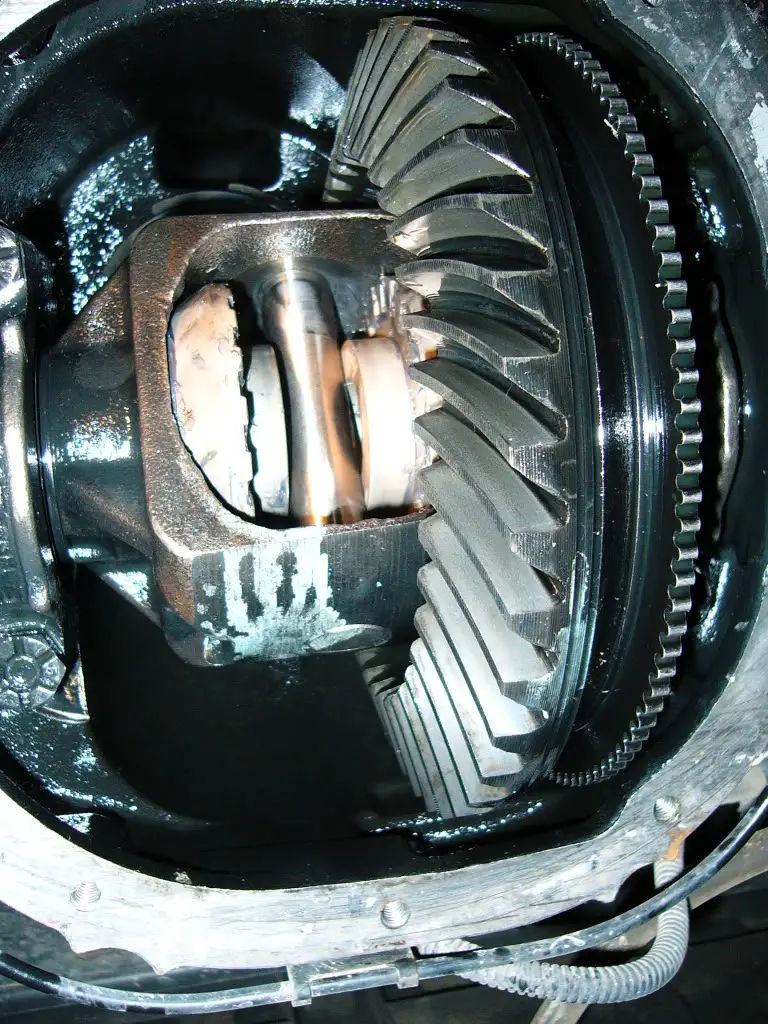

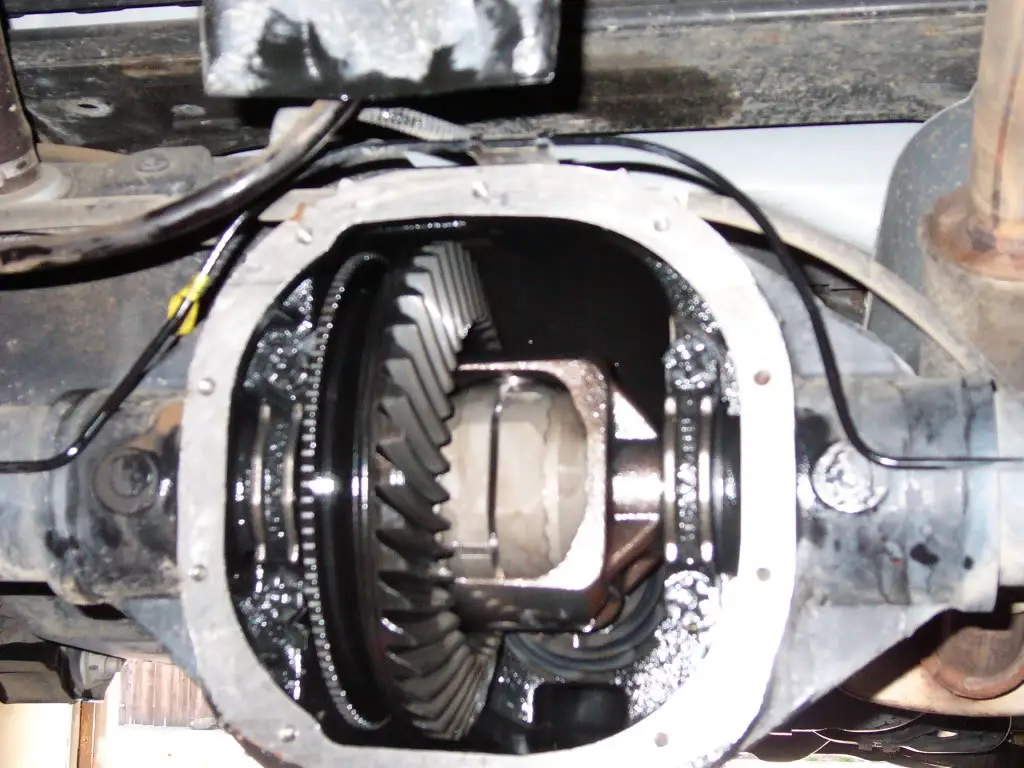

now that all of the fluid is drained, this is what the inside of your diff looks like. (dont be intimidated by all the fancy gears!)

the gears on that are on the top and bottom that spin from side to side and held by the carrier pin are the spider gears. the slightly larger gears are the axle gears, (like the name says, these gears are attached and spin to the axles. in the bottom photo, if you look closely in the center of the axle gear, the black part is the end of the left axle and attached to it is the c-clip. the large gear to the left is your ring which is spun by your pinion which is connected to the driveshaft (not pictured). the shaft in the center that is vertical is your carrier pin, and the housing that all of the gears (except for the ring) is the carrier.

wipe up the residual oil in the diff with a rag and make sure you dont leave any rag bits inside the diff when you are done. use some brake cleaner and clean that thing up!

once you have it all cleaned up, use a 5/16'' box wrench and remove the carrier pin retaining bolt. it will be on the top of the carrier. turn the carrier in a 45 degree angle downward, and be careful not to break the head off of the retaining bolt.

this is a picture of the carrier pin pulled halfway out with the retaining bolt on it just to give you a visual of the parts.

here's a clearer pic of the first pieces to come out. (from left to right)

spider gears, carrier pin, carrier pin retaining bolt.

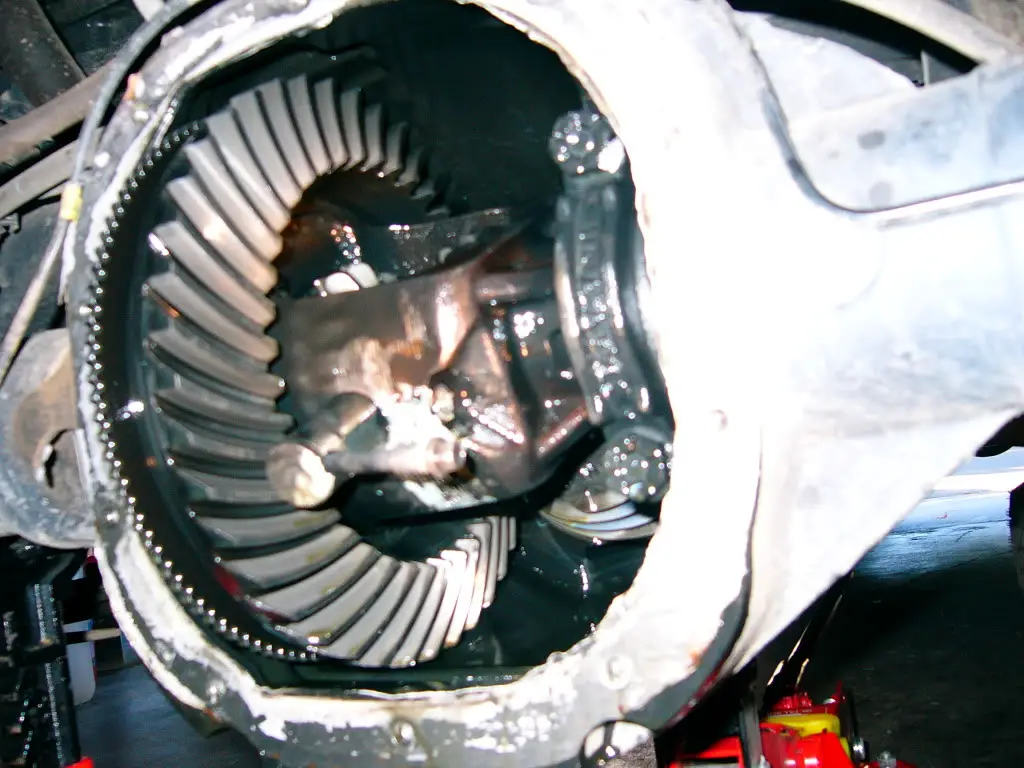

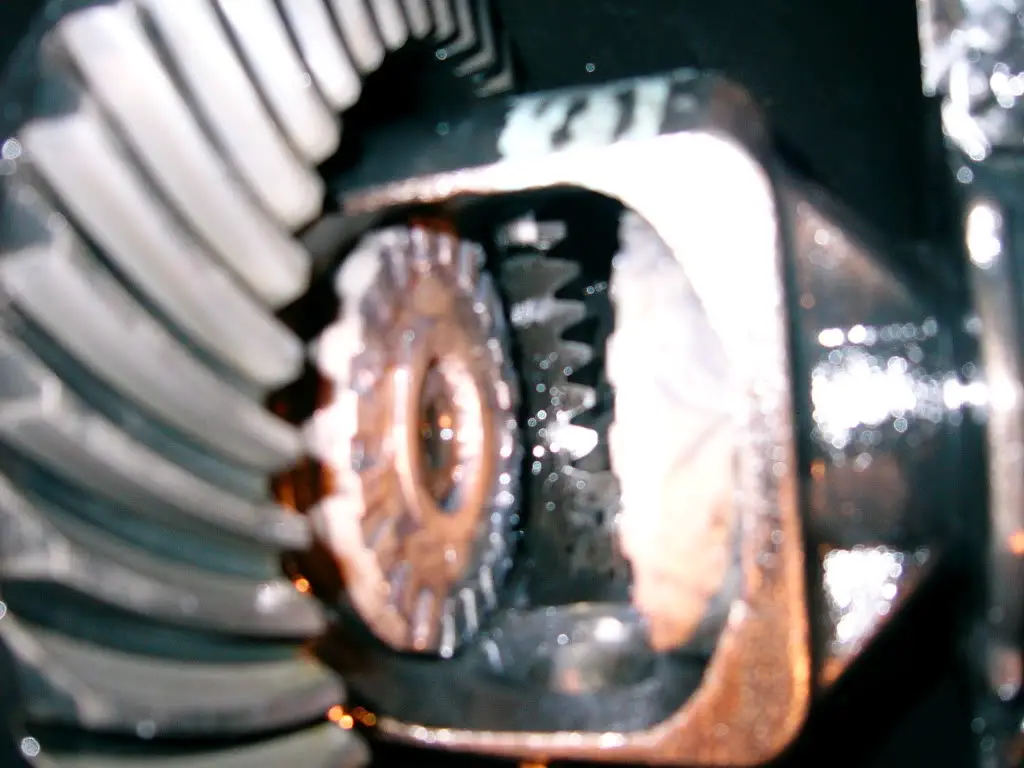

here is a picture to give you a good visual without the spider gears. with the spider gears removed, you can see the axle gears on the left and right of the carrier. in the center of the left axle gear in this pic, you can see the end of the axle, and the c-clip holding it in place (c-clip looks like a U in this picture).

how to remove the c-clips? you have to remove the brake calipers first. there are two bolts holding each caliper in place, they are in the backside of the caliper.

with the calipers removed, you now have a little play with the axles. push the axles in, this will give you slack to remove the c-clips. then you can pull the axles out after the clips are removed, and then you can remove the axle gears. make sure you pull the thrust washers and the spider gear washers. dont leave them in the carrier!

this is a picture of the pieces just removed for a good visual of what you are to be removing. (form left to right) c-clips, thrust washers, axle gears.

the first mistake i made was using the axle grease on the locker pieces when i first installed them into the carrier. the first thing you MUST DO is measure for gap clearances and the grease will most likely throw your measurements off. so perform this initial install step and following steps without grease! it might be harder to keep all of the pieces together, but trust me, the grease had me racking my brain for a whole night as to why i couldnt get my clearances right.

this is where it gets a bit tricky:

with the c clips removed, slap your new aussie locker axle gears (the ones with splines) onto each axle. make sure you place a thrust washer onto each aussie locker axle gear before you throw them onto the axles. place them onto the aussie locker axle gears the same way you found them on your original axle gears.

next, put the c clips on and place the axles in the position they would normally sit when they are operational. you can line this back up by throwing the calipers back on (you dont have to screw them back in place) over the rotors.

after this is done, place and hold the supplied aussie locker spacers to the center of the axle gears with the open end covering the c clips.

next, slide the carrier pin back into its slot down the middle and hold it there with the retaining bolt. it should now look like this: (the pic is upside down but you get the idea)

now its time for the feeler gauges. use the feeler gauges to measure the gap between the center pin and the spacers. this gap needs to be within spec as per the instructions in the supplied manual. there has been a ton of talk about this on the forum, some guys are ok with being slightly out of spec, some guys find ways to get within spec. i got right within the limits once i removed all of the grease i used to hold the locker pieces together so hopefully with you not using any grease, you will be within spec too and avoid all the controversy! its your call as to what you want to do if you dont fall within range on your gap spacing. please search further on the forum for more info (look for ronin's irs locker install).

after you have measured your spacing, remove the carrier pin and spacers, but leave the axle gears on.

next install the precision pins into the cam gears. the nipple side of the pins should go into the open holes with the nipple side in. follow the picture from the instructions.

once you find yourself within range, move onto the next phase, getting the cam gears and c clips back on!

here is a quick video explanation i did on how to get the aussie locker components on. please forgive me for the bad lighting (i was working at night), just listen to my explanation and look at the photos above and it will make much more sense!

http://www.youtube.com/watch?v=fib3AKNob28

here is another video in the dark of me explaining how i got the cam gears in. once you watch this video, hopefully you will be able to visualize getting the last cam gear in.

http://www.youtube.com/watch?v=sU8PgmAZbXw

ok, so if you follow the instructions supplied with the lockers to a T, the lockers will go in exactly as they say they will, but the problem is, it is a little hard to visualize the method of actually doing it. i will try to explain a little simpler.

after the clearance test, the only aussie parts that should be installed at this point are the axle gears with thrust washers. the first cam gear to go in is the ring side (left). make sure you have removed the calipers from the rotors and that the axles are free to move. (this would be a good time to get your buddy involved). have him slide the left axle inward by pushing on the rotor just slightly while you make sure the axle gear splines line up and allow the axle to pass through. place a c clip onto the axle and have your buddy pull on the rotor so that the c clip seats itself. slide the cam gear over the axle and make sure the teeth (on the cam gear) are matching up with the teeth on the axle gear.now place the space in the center of the cam gear with the open side of the spacer fitting over the c clip. the cam gear and the spacer should be flush.

now the tricky part:

bend your coat hanger so that at the end of it, you make a "U". make it the size of the recess on the cam gear that you have not yet put into the carrier.

slide the last spacer inside the last cam gear and then slide the two pieces as one into the carrier. it will get a little tight, but heres where the hanger comes in.

have the recessed side of the right cam gear face you, and then slide the coat hanger in between the teeth of the right cam gear and axle gear. now push the spacer to the left until it is in between both cam gears. if you get this right, then right on! the whole locker should be holding together precariously with the right spacer.

have your buddy ever so gently, slide the right axle very slowly until you can see the recess on the axle where the c clip clips onto. it should be lined up right in between the teeth of the right cam and axle gear. make sure you have a good flashlight or headlamp that is nice and bright.

now, with the recessed side of the right cam gear still facing you, slide the last remaining c clip in between the teeth of the right cam and axle gears. once the c clip is biting the axle, have your buddy turn the right axle a 1/4 clockwise so that the c clip falls onto place and seats itself onto the axle.

if you get this right, then the hardest part is over!

now you have to push the right cam and axle gear together, line up the slot for the carrier pin, and then use this empty space to slide the right spacer to the right so that it sits over the c clip properly.

now that this is done, it is time for the second hardest part. putting on the springs!

with the cam gear slots lined up so that the the carrier pin is back in place and being held by the retaining bolt, it is time to slide the pins from the open hole over to the "closed" hole that they match up with. i used the tip of my finger with a latex glove on to slide the pins over, u might be able to use a very narrow headed flathead screw driver to do the same, just dont damage the locker. the nipple on the pin should now be exposed and the pin should be sitting in the hole with the closed side.

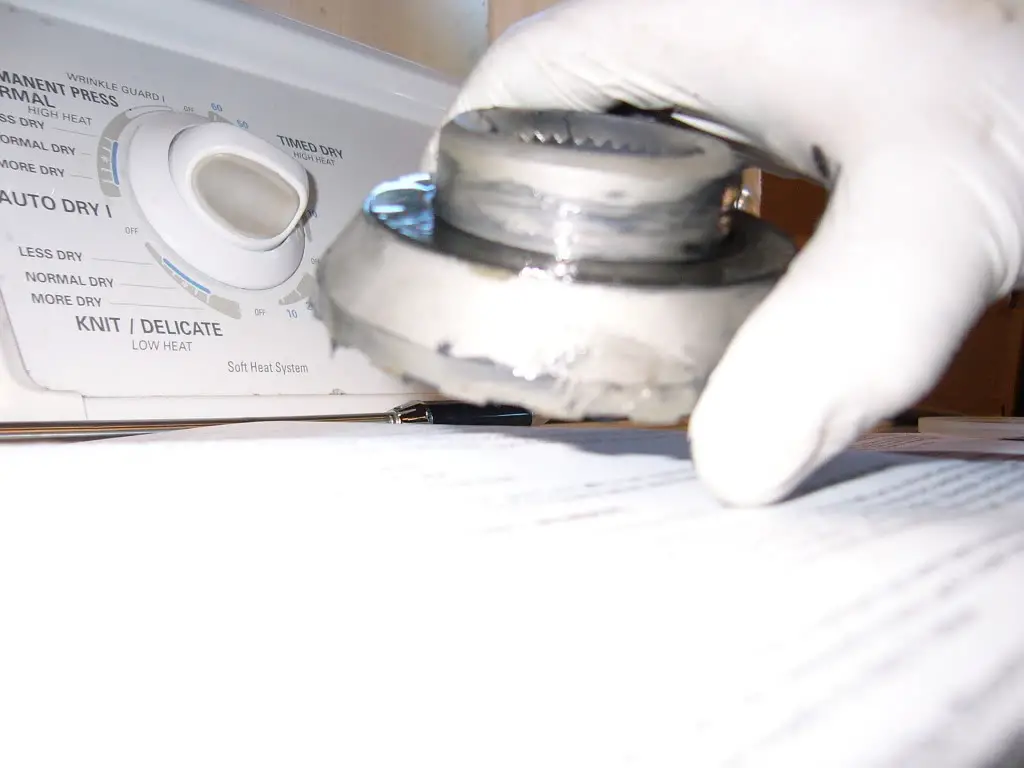

now carefully slide the spring over the nipple and then seat it all the way inside the slot hole. make sure it is in there good and proper! i used a very thin flathead screwdriver and very thin needle nose pliers to guide the springs in. try not to let them fly because if you lose one, thats 20 bucks! the way i got the springs on with the screwdriver and pliers was i placed the spring over the nipple, put the screwgie just slightly inside the spring, compressed it, and keeping the pliers closed, used the nose of the pliers to push the spring in place. the spring should look like this:

now turn the locker and do the other 3! be patient, take your time and do it right. take breaks in between springs so you keep from getting frustrated if you find this part difficult. the more you rush the more you increase the chance of forcing the spring in and cause it to fly across your garage.

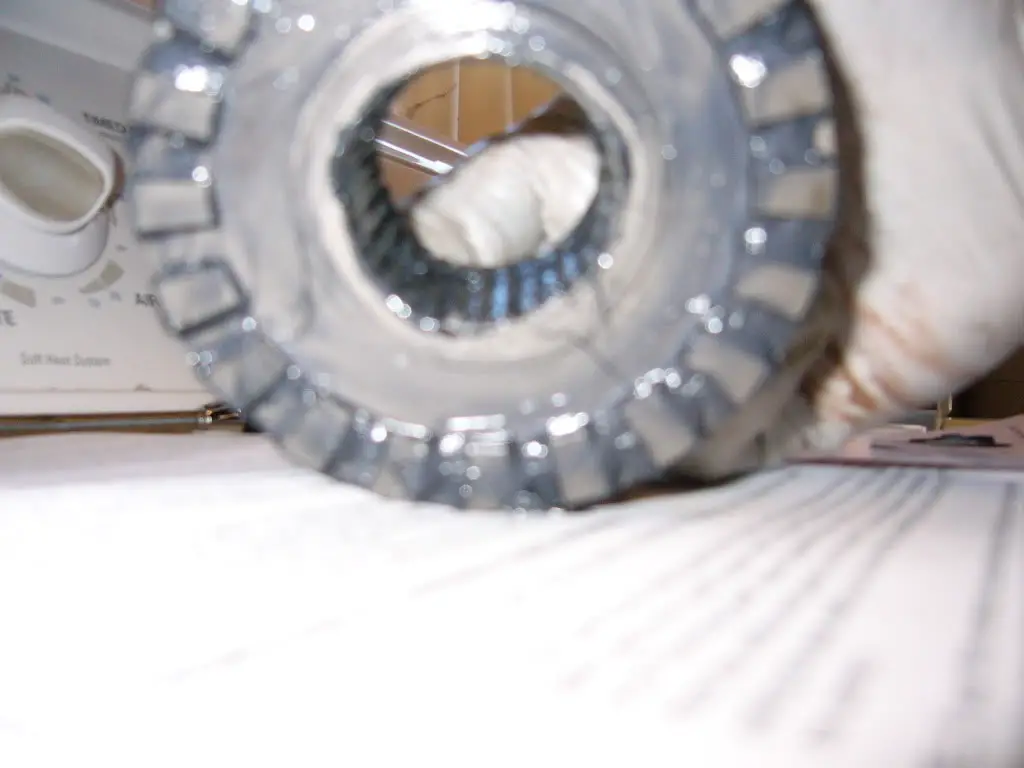

now that the pins are in, you need to measure one more gap for spacing. measure the spacing between the cam gears and make sure it is within spec per the instructions. if your carrier pin slid back in place with no friction, then you should be in a good spot. same as before with the first measurements. do it right! your locker should now look like this:

now that this last measurement is done and you have passed the clearance test, here's the crappiest step: take it all apart!

yes, once you get your measurements to pass, take the whole thing apart and this time assemble it using the same steps only this time grease your aussie locker components. this is important because they will need some kind of lube to help them when they first get turned. it will also protect the parts during the break in period.

some people will put the grease on during the first install, but this might throw off your gap measurements, so it's up to you how you want to do this. put the grease on first, or install it and make sure your spacing is good and then put it all back together, its up to you. just remember that these aussie lockers are not cheap (at least not to me) and i dont want to have to open my diff up again because the lockers failed on me and to top that off, i didnt get my measurements right so now my warranty is void. thats why i suggest doing it this way. if youre gonna do it, do it right so there is no doubt in your mind that they are in correctly and more importantly, SAFELY!

besides, the first night i installed my aussie lockers with the grease, i couldnt figure out why my clearances were off. i racked my brain until i talked to a couple guys on the forum and bill cole from aussie. doing it this way will clear any doubt that you are good to go. i know i wouldnt want to half ass it and be on the trails or far from home wondering if my locker is going to give,.

make sure you use the new carrier pin retaining bolt on your final greased install, and whether you opted for a new retaining bolt or not make sure you put plenty of thread locker on it.

now that you have taken apart your locker, greased it, and put it back together, is it spinning correctly? does everything look good visually? well then now it's time for the all important spin test.

you must pass this spin test with flying colors before you go on and finish things up. test it twice, even three times to make sure things are kosher. here is a video (good lighting) of how to do the test without the help of a friend.

http://www.youtube.com/watch?v=xWF2JY4bNDg&feature=related

to perform the spin test, first place the truck into gear

next, spin the left wheel forward until the driveshaft is spinning. now get your beer drinking buddy to hold the wheel still.

now go to the right wheel and spin it backwards. give it a good spin. the lockers should start to ratchet cleanly. now spin the left wheel backwards.

have your buddy hold it still, and now spin the right wheel forward. it should ratchet cleanly.

now perform this test to the right wheel.

if you pass this test perfectly, it is time to close your diff up. you are almost there!

having cleaned the diff cover and diff, place a bead of RTV on the diff cover all the way around. slap the diff cover on lining up all of the bolt holes. i used a little thread locker with each diff bolt for some insurance and then bolted the bolts back on.

wait a little while, have another beer (i drank a 12 pack of pacificos during my install, your choice) and now its time to put the new fluids in.

remove the diff plug using your 3/8'' ratchet extension and get your super funnel or pump ready. start putting in the new fluid. have patience, this stuff moves like glaciers.

this could get messy, and for a solid axle 8.8 rear, you will need 2.5 quarts of the stuff. i went synthetic myself on this one just to treat the 'ol girl.

once topped off, put some RTV or some thread locker on the diff plug and screw back in.

reinstall your sway bar.

now you are a proud owner of a locked out truck!!!

take it easy and get a feel of the difference in how your truck will drive. it will hop around, and chirp much more and the ratcheting noise on sharp turns will take some getting used to, but over this past weekend ive learned to love it. i actually like the sound of the ratcheting. it might get old later on but right now, not only does it feel like im on tank tracks in the rear, but it sounds like im driving a tank too!

i did some minor off road testing and man, no spin, and i was cutting through sand and ruts and all kinds of stuff like i was driving on paved road.

hopefully this how to helps you out, makes it easier, or convinces you to make the leap and get some lockers. right now me and the gf are trying to figure out where we are going to next weekend to test out the new lockers for real and we are juiced!

doing this the first time, my total install time was in between 4 and 5 hours which bled across from one evening into another morning. having already performed the install, i think i could do it again in about 2 hours if i had all the materials ready, and i think that once my buddies see the difference it makes, i will be helping them drop one in their rigs too.

total spent: 300.00 for the lockers shipped, 50 dollars for materials listed above like gear oil, super funnel, cleaner, rtv, etc. grand total was just under 360 dollars for the best dollar for dollar value mod you can make.

please, if i left anything out, add it to this thread. if you have any tips or suggestions, add it, if i made any mistakes, add it, and if you have any questions, just leave a comment or PM me. good luck on your install and thanks to everyone on the forum who helped me with this.

PLEASE READ OVER THIS HOW TO AT LEAST ONCE OVER BEFORE YOU START YOUR INSTALL!!!

the best thing you can do if you arent familiar with lockers (like me) is to do a lot of reading on this forum and other websites on what lockers do, and determine if this is something you want in your rig. now that i have them on mine, i love them but that might not be the same for everyone. also do some homework and get familiar with how and why differentials work and what their function is. then the install will be much more easier on you. this install should translate in principle to other lunchbox lockers like the richmond powertrax locker as well.

this is a how to on locker installs for the everyday guy who is moderately mechanically inclined (such as me) but were too intimidated by all of those gears in your diff. post any questions if you have them and good luck on your install!

first things first: the aussie locker model# for the ford 8.8 solid axle open differential is the XD48831.

here are the materials you will need to complete the install:

3 qts. of gear oil, i used 75w140, but other members have told me that they run 85w140 in hotter climates, ultrablack RTV, brake cleaner, bearing grease, feeler gauge, super funnel, carrier pin retaining bolt, WD40, PB blaster, a super funnel or some sort of pump to get the new diff fluid in, two jack stands, a jack, and a buddy if available (just bribe with beer).

no special tools needed for this particular axle, a standard socket set with 3/8 adapter, a set of wrenches with box ends, assorted pliers, a crescent wrench, razor blade, flathead screwdrivers (assorted widths) a rubber mallet, and the thinnest wire coat hanger you can find in your closet (remember, the thinnest you can find!).

try to soak the diff plug, your sway bar bolts, diff cover bolts and all other bolts with the pb blaster the day before you install, it will make everything much easier.

remove the spare tire to give yourself some room under there. if youve never taken off your spare before, use the jack equipment and find the hole under the tailgate and spin that tire down.

block the front wheels with some blocks, or spare wheels or chocks. then release the e brake and put the truck in N, jack the rear end up, and place the jack stands under the axles. i like to put the spare wheel under the truck as well as an insurance policy just in case.

next, you want to remove your sway bar for more room. the easiest way is to

remove the bottom bolts holding your rear shocks, then remove all of the bolts attaching the sway bar to the axle and swaybar arms.

then, find the diff plug and soak it with some PB blaster and use your ratchet adapter (3/8) and see if you can loosen the plug before you can do anything else, but dont pull it off just yet.

next, loosen the diff cover bolts. loosen the top bolt, but dont take it off, once all of but the top bolt are removed, put a drip pan under the diff, use a flathead screwdriver and pry the diff cover from the bottom enough until the fluid starts to drip into the pan.

there is a how to on the forum on changing your diff fluid. it should help if you are still uncomfortable with doing this part.

give it a little while for all the oil to spill out of the diff. that stuff moves like molasses, so be patient.

next, it would be good to clean your diff cover. wipe the residual oil from it, then clean it with some brake cleaner. then use a razor to clean off the old gasket or RTV silicone.

now that all of the fluid is drained, this is what the inside of your diff looks like. (dont be intimidated by all the fancy gears!)

the gears on that are on the top and bottom that spin from side to side and held by the carrier pin are the spider gears. the slightly larger gears are the axle gears, (like the name says, these gears are attached and spin to the axles. in the bottom photo, if you look closely in the center of the axle gear, the black part is the end of the left axle and attached to it is the c-clip. the large gear to the left is your ring which is spun by your pinion which is connected to the driveshaft (not pictured). the shaft in the center that is vertical is your carrier pin, and the housing that all of the gears (except for the ring) is the carrier.

wipe up the residual oil in the diff with a rag and make sure you dont leave any rag bits inside the diff when you are done. use some brake cleaner and clean that thing up!

once you have it all cleaned up, use a 5/16'' box wrench and remove the carrier pin retaining bolt. it will be on the top of the carrier. turn the carrier in a 45 degree angle downward, and be careful not to break the head off of the retaining bolt.

this is a picture of the carrier pin pulled halfway out with the retaining bolt on it just to give you a visual of the parts.

here's a clearer pic of the first pieces to come out. (from left to right)

spider gears, carrier pin, carrier pin retaining bolt.

here is a picture to give you a good visual without the spider gears. with the spider gears removed, you can see the axle gears on the left and right of the carrier. in the center of the left axle gear in this pic, you can see the end of the axle, and the c-clip holding it in place (c-clip looks like a U in this picture).

how to remove the c-clips? you have to remove the brake calipers first. there are two bolts holding each caliper in place, they are in the backside of the caliper.

with the calipers removed, you now have a little play with the axles. push the axles in, this will give you slack to remove the c-clips. then you can pull the axles out after the clips are removed, and then you can remove the axle gears. make sure you pull the thrust washers and the spider gear washers. dont leave them in the carrier!

this is a picture of the pieces just removed for a good visual of what you are to be removing. (form left to right) c-clips, thrust washers, axle gears.

the first mistake i made was using the axle grease on the locker pieces when i first installed them into the carrier. the first thing you MUST DO is measure for gap clearances and the grease will most likely throw your measurements off. so perform this initial install step and following steps without grease! it might be harder to keep all of the pieces together, but trust me, the grease had me racking my brain for a whole night as to why i couldnt get my clearances right.

this is where it gets a bit tricky:

with the c clips removed, slap your new aussie locker axle gears (the ones with splines) onto each axle. make sure you place a thrust washer onto each aussie locker axle gear before you throw them onto the axles. place them onto the aussie locker axle gears the same way you found them on your original axle gears.

next, put the c clips on and place the axles in the position they would normally sit when they are operational. you can line this back up by throwing the calipers back on (you dont have to screw them back in place) over the rotors.

after this is done, place and hold the supplied aussie locker spacers to the center of the axle gears with the open end covering the c clips.

next, slide the carrier pin back into its slot down the middle and hold it there with the retaining bolt. it should now look like this: (the pic is upside down but you get the idea)

now its time for the feeler gauges. use the feeler gauges to measure the gap between the center pin and the spacers. this gap needs to be within spec as per the instructions in the supplied manual. there has been a ton of talk about this on the forum, some guys are ok with being slightly out of spec, some guys find ways to get within spec. i got right within the limits once i removed all of the grease i used to hold the locker pieces together so hopefully with you not using any grease, you will be within spec too and avoid all the controversy! its your call as to what you want to do if you dont fall within range on your gap spacing. please search further on the forum for more info (look for ronin's irs locker install).

after you have measured your spacing, remove the carrier pin and spacers, but leave the axle gears on.

next install the precision pins into the cam gears. the nipple side of the pins should go into the open holes with the nipple side in. follow the picture from the instructions.

once you find yourself within range, move onto the next phase, getting the cam gears and c clips back on!

here is a quick video explanation i did on how to get the aussie locker components on. please forgive me for the bad lighting (i was working at night), just listen to my explanation and look at the photos above and it will make much more sense!

http://www.youtube.com/watch?v=fib3AKNob28

here is another video in the dark of me explaining how i got the cam gears in. once you watch this video, hopefully you will be able to visualize getting the last cam gear in.

http://www.youtube.com/watch?v=sU8PgmAZbXw

ok, so if you follow the instructions supplied with the lockers to a T, the lockers will go in exactly as they say they will, but the problem is, it is a little hard to visualize the method of actually doing it. i will try to explain a little simpler.

after the clearance test, the only aussie parts that should be installed at this point are the axle gears with thrust washers. the first cam gear to go in is the ring side (left). make sure you have removed the calipers from the rotors and that the axles are free to move. (this would be a good time to get your buddy involved). have him slide the left axle inward by pushing on the rotor just slightly while you make sure the axle gear splines line up and allow the axle to pass through. place a c clip onto the axle and have your buddy pull on the rotor so that the c clip seats itself. slide the cam gear over the axle and make sure the teeth (on the cam gear) are matching up with the teeth on the axle gear.now place the space in the center of the cam gear with the open side of the spacer fitting over the c clip. the cam gear and the spacer should be flush.

now the tricky part:

bend your coat hanger so that at the end of it, you make a "U". make it the size of the recess on the cam gear that you have not yet put into the carrier.

slide the last spacer inside the last cam gear and then slide the two pieces as one into the carrier. it will get a little tight, but heres where the hanger comes in.

have the recessed side of the right cam gear face you, and then slide the coat hanger in between the teeth of the right cam gear and axle gear. now push the spacer to the left until it is in between both cam gears. if you get this right, then right on! the whole locker should be holding together precariously with the right spacer.

have your buddy ever so gently, slide the right axle very slowly until you can see the recess on the axle where the c clip clips onto. it should be lined up right in between the teeth of the right cam and axle gear. make sure you have a good flashlight or headlamp that is nice and bright.

now, with the recessed side of the right cam gear still facing you, slide the last remaining c clip in between the teeth of the right cam and axle gears. once the c clip is biting the axle, have your buddy turn the right axle a 1/4 clockwise so that the c clip falls onto place and seats itself onto the axle.

if you get this right, then the hardest part is over!

now you have to push the right cam and axle gear together, line up the slot for the carrier pin, and then use this empty space to slide the right spacer to the right so that it sits over the c clip properly.

now that this is done, it is time for the second hardest part. putting on the springs!

with the cam gear slots lined up so that the the carrier pin is back in place and being held by the retaining bolt, it is time to slide the pins from the open hole over to the "closed" hole that they match up with. i used the tip of my finger with a latex glove on to slide the pins over, u might be able to use a very narrow headed flathead screw driver to do the same, just dont damage the locker. the nipple on the pin should now be exposed and the pin should be sitting in the hole with the closed side.

now carefully slide the spring over the nipple and then seat it all the way inside the slot hole. make sure it is in there good and proper! i used a very thin flathead screwdriver and very thin needle nose pliers to guide the springs in. try not to let them fly because if you lose one, thats 20 bucks! the way i got the springs on with the screwdriver and pliers was i placed the spring over the nipple, put the screwgie just slightly inside the spring, compressed it, and keeping the pliers closed, used the nose of the pliers to push the spring in place. the spring should look like this:

now turn the locker and do the other 3! be patient, take your time and do it right. take breaks in between springs so you keep from getting frustrated if you find this part difficult. the more you rush the more you increase the chance of forcing the spring in and cause it to fly across your garage.

now that the pins are in, you need to measure one more gap for spacing. measure the spacing between the cam gears and make sure it is within spec per the instructions. if your carrier pin slid back in place with no friction, then you should be in a good spot. same as before with the first measurements. do it right! your locker should now look like this:

now that this last measurement is done and you have passed the clearance test, here's the crappiest step: take it all apart!

yes, once you get your measurements to pass, take the whole thing apart and this time assemble it using the same steps only this time grease your aussie locker components. this is important because they will need some kind of lube to help them when they first get turned. it will also protect the parts during the break in period.

some people will put the grease on during the first install, but this might throw off your gap measurements, so it's up to you how you want to do this. put the grease on first, or install it and make sure your spacing is good and then put it all back together, its up to you. just remember that these aussie lockers are not cheap (at least not to me) and i dont want to have to open my diff up again because the lockers failed on me and to top that off, i didnt get my measurements right so now my warranty is void. thats why i suggest doing it this way. if youre gonna do it, do it right so there is no doubt in your mind that they are in correctly and more importantly, SAFELY!

besides, the first night i installed my aussie lockers with the grease, i couldnt figure out why my clearances were off. i racked my brain until i talked to a couple guys on the forum and bill cole from aussie. doing it this way will clear any doubt that you are good to go. i know i wouldnt want to half ass it and be on the trails or far from home wondering if my locker is going to give,.

make sure you use the new carrier pin retaining bolt on your final greased install, and whether you opted for a new retaining bolt or not make sure you put plenty of thread locker on it.

now that you have taken apart your locker, greased it, and put it back together, is it spinning correctly? does everything look good visually? well then now it's time for the all important spin test.

you must pass this spin test with flying colors before you go on and finish things up. test it twice, even three times to make sure things are kosher. here is a video (good lighting) of how to do the test without the help of a friend.

http://www.youtube.com/watch?v=xWF2JY4bNDg&feature=related

to perform the spin test, first place the truck into gear

next, spin the left wheel forward until the driveshaft is spinning. now get your beer drinking buddy to hold the wheel still.

now go to the right wheel and spin it backwards. give it a good spin. the lockers should start to ratchet cleanly. now spin the left wheel backwards.

have your buddy hold it still, and now spin the right wheel forward. it should ratchet cleanly.

now perform this test to the right wheel.

if you pass this test perfectly, it is time to close your diff up. you are almost there!

having cleaned the diff cover and diff, place a bead of RTV on the diff cover all the way around. slap the diff cover on lining up all of the bolt holes. i used a little thread locker with each diff bolt for some insurance and then bolted the bolts back on.

wait a little while, have another beer (i drank a 12 pack of pacificos during my install, your choice) and now its time to put the new fluids in.

remove the diff plug using your 3/8'' ratchet extension and get your super funnel or pump ready. start putting in the new fluid. have patience, this stuff moves like glaciers.

this could get messy, and for a solid axle 8.8 rear, you will need 2.5 quarts of the stuff. i went synthetic myself on this one just to treat the 'ol girl.

once topped off, put some RTV or some thread locker on the diff plug and screw back in.

reinstall your sway bar.

now you are a proud owner of a locked out truck!!!

take it easy and get a feel of the difference in how your truck will drive. it will hop around, and chirp much more and the ratcheting noise on sharp turns will take some getting used to, but over this past weekend ive learned to love it. i actually like the sound of the ratcheting. it might get old later on but right now, not only does it feel like im on tank tracks in the rear, but it sounds like im driving a tank too!

i did some minor off road testing and man, no spin, and i was cutting through sand and ruts and all kinds of stuff like i was driving on paved road.

hopefully this how to helps you out, makes it easier, or convinces you to make the leap and get some lockers. right now me and the gf are trying to figure out where we are going to next weekend to test out the new lockers for real and we are juiced!

doing this the first time, my total install time was in between 4 and 5 hours which bled across from one evening into another morning. having already performed the install, i think i could do it again in about 2 hours if i had all the materials ready, and i think that once my buddies see the difference it makes, i will be helping them drop one in their rigs too.

total spent: 300.00 for the lockers shipped, 50 dollars for materials listed above like gear oil, super funnel, cleaner, rtv, etc. grand total was just under 360 dollars for the best dollar for dollar value mod you can make.

please, if i left anything out, add it to this thread. if you have any tips or suggestions, add it, if i made any mistakes, add it, and if you have any questions, just leave a comment or PM me. good luck on your install and thanks to everyone on the forum who helped me with this.