arco777

Explorer Addict

- Joined

- April 6, 2008

- Messages

- 2,404

- Reaction score

- 59

- Year, Model & Trim Level

- 1994 Explorer 2dr 4x4

This thread will compare a stock 1994 4.0 oil pump and a new Melling M328 high volume replacement pump.

Melling pump info: http://omnitek.co/mellingcatalog/#ag/part/M328

I purchased the M328 for approximately $140 through a site that shares its name with a river. The stock pump we are comparing is the original from my '94 Explorer with 197k miles on it. The motor had solid oil pressure (gauge was modified).

First, initial comparison has both pumps showing approximately the same external dimensions. The Ford pump's finish is smooth and the Melling's is rough. I note the spot where the drive shaft enters the pump appears to have less engagement surface on the Melling, but hopefully the unit sits farther up on the shaft.

I note that there is a spot which is covered by the gasket on the old one; pulling off the gasket (and comparing the new gasket) indicates that both units are supposed to have the gasket covering it even though there are threads. It's too difficult to get a picture inside this chamber but it appears ribbed or to have a spring. It's visible in further pictures and seems to be a pressure release valve.

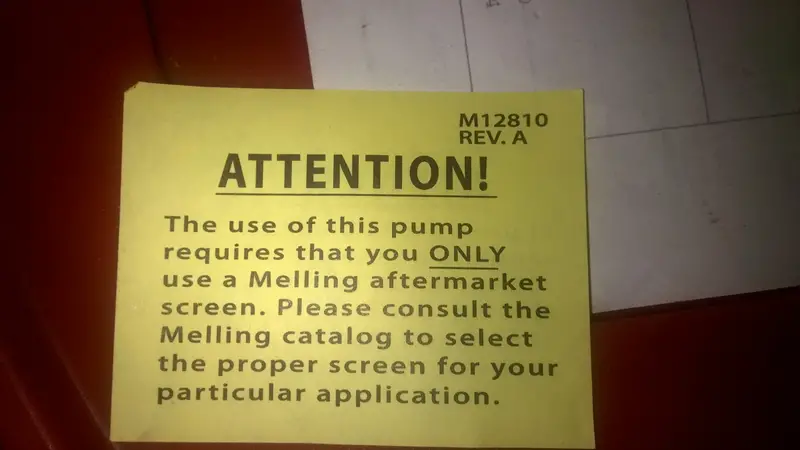

The new Melling comes with a note specifying it requires a new Melling oil pickup. I'm guessing this may be due to the warranty requirements rather than a difference in parts.

Melling pump info: http://omnitek.co/mellingcatalog/#ag/part/M328

I purchased the M328 for approximately $140 through a site that shares its name with a river. The stock pump we are comparing is the original from my '94 Explorer with 197k miles on it. The motor had solid oil pressure (gauge was modified).

First, initial comparison has both pumps showing approximately the same external dimensions. The Ford pump's finish is smooth and the Melling's is rough. I note the spot where the drive shaft enters the pump appears to have less engagement surface on the Melling, but hopefully the unit sits farther up on the shaft.

I note that there is a spot which is covered by the gasket on the old one; pulling off the gasket (and comparing the new gasket) indicates that both units are supposed to have the gasket covering it even though there are threads. It's too difficult to get a picture inside this chamber but it appears ribbed or to have a spring. It's visible in further pictures and seems to be a pressure release valve.

The new Melling comes with a note specifying it requires a new Melling oil pickup. I'm guessing this may be due to the warranty requirements rather than a difference in parts.