High_Order1

Well-Known Member

- Joined

- January 31, 2007

- Messages

- 493

- Reaction score

- 4

- City, State

- near Oak Ridge, TN

- Year, Model & Trim Level

- 2005 Jack Bauer Edition

How I solved the gas gauge problem on my 2005 Flex Fuel Ford Explorer

Difficulty: Above Average, for two reasons; 1) you wind up cutting a permanent, gaping hole into your car, and 2) you're dealing with gasoline and critical systems. If you have access to the tools, the time, and can follow this, you can do this.

Tools: saber saw with metal blade, screwdrivers, socket set (I forget which specifically, sry) with extensions, volt-ohm meter

Next, a word about gasoline

Too many people have gotten weird ideas about how gasoline behaves. Mostly from 'friend-of-a-friend' stories, and a LOT from Hollywood. See, real life is too boring for movie crews, so, they have to spice things up often. This is why every car, even with minor damage, makes the huge BOOM, and the cool fireball (except the hero car, which can be shot completely up, rammed, and jump through the air, but not even shift funny, but I digress).

The primary danger with gas is what nerds call the vapor phase. The liquid is surprisingly stable. I have seen many, many times where stuff shoulda caused the BOOM, not cause it. On the other hand, when the vapor comes out, that’s when Mister Gas Quits Being Reasonable and starts being the animal it really is.

What does this mean to you? Many people don't mess with certain repairs, because They Fear The BOOM. As long as you follow a few rules, you'll be fine. First, if you get a puddle or a spill, stop what you're doing and clean it up. Second, have lots of fresh ventilation. Third, avoid working on the car when the exhaust is hot. And, if you pull the pump, put something over the hole while its' gone. Past that, as long as you aren't carrying static, or making sparks, you should be fine.

And, if you don't believe me, then why are most fuel tanks made out of plastic now, instead of metal? And, why aren't there more explosions at filling stations?

BEFORE YOU BEGIN!

Listen to me. Seriously. This isn't the normal car you're used to. It is a rolling computer, and it is so, so, SO sensitive to battery shape. BEFORE you waste days going through all this other crap, go check yer battery. If it is a few volts shy at rest, try charging it with a real charger (your alternator won’t suffice), or replace it. If it drops below 10v while cranking, replace it. Period. If the terminals are a little crapped up, FIX THEM. No green, no dirt, clean and tight. Don't hesitate to whack a terminal connector off and replace them. SERIOUSLY.

There are a TON of gremlins and transient issues that can only be solved with a good battery. I don't care if its' 6 months or 6 years old. Don't assume your battery is good. I promise.

OK - a backgrounder on this retarded/genius gas system

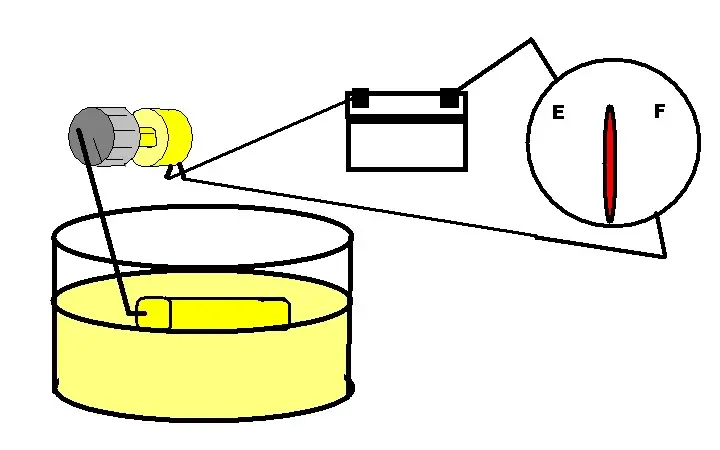

In my first car, here is how it worked-

In the fuel tank is a float. This float is connected by an arm to for all intents and purposes, a volume knob. As the level of fuel rises, the float also rises, and turns the knob one way. As it drops, the knob turns the other way. The knob is actually a variable resistor, and turning it changes the value of resistance.

You put electricity through it, and attach a voltmeter to the other side, and voila! Gas Gauge!

Well, in the flex fuel Ford, there are a number of complications.

First, for some reason unknown to me, Ford thinks sending direct current through the fuel sensor in a tank full of ethanol is a bad idea. (I even researched it, and couldn't come up with anything. I am guessing the alcohol has some kind of electroplating effect on the resistor part over time. Just a guess).

So, in between the wire and the fuel sensor / volume knob, there is a DC to AC converter.

On the other end, we no longer have a simple, analog car. What we have basically is a computer with wheels that can’t understand the volume knob (analog) input.

So, now, at the used-to-be-dashboard-now-we-call-it-an-instrument-cluster, there is an analog-to-digital converter. Continuously variable voltage goes in one side, a digital signal that is a binary number proportionate to the amount of fuel in the tank comes out the other side.

But wait, there's more!

See, the master computer what runs everything in the car doesn't like the fact that as the car moves, the float is continuously in motion and therefore continuously sending varying data to the computer and the cluster. Nope. So, it has a computer program that interprets the data it is seeing, and compares it with information from other sensors and timers, and THEN, sends a signal to the little needle telling you its' time to feed the hog again.

So, if you’re keeping count, it goes sender > harness with connectors > digital to analog converter > computer > fuel gauge

Seriously! There are 3-4 fuel gauge programs or 'strategies' that the car is continuously running.

The first one, is called 'Anti-Slosh Mode'. You are normally in this mode. Basically, the system averages the readings it sees over time then adjusts the needle to match. Unless you're standing still, and not sloshing, you really aren't seeing the true tank level.

The second and third (and maybe fourth, I forget now) strategies kick in when there's been a gap in the continuous data, or there's been a large change in the data.

IF THE KEY WAS OFF, and there has been a large change in the current data (in other words, you put at least 15% more gas in it than it had) from the stored value, there is a small delay where the needle does nothing while the computer averages things. Then, it reverts back to antislosh.

IF THE KEY WAS ON, oh boy. You just invoked a series of timers, that unless defeated by turning the car off for a period of time, can wait up to 55 MINUTES to watch the system settle before adjusting the needle. This isn't an error, it is a factory programmed strategy.

The last strategy is similar to key on / data change, and it gets invoked if there was a gap in data, like an intermittent short, or bus error or something.

In simpler words, refuel with the car off; your gauge will be pretty accurate (everything else notwithstanding). Refuel with the car on, and it will take foooorever to reflect the new level.

Why does it need all this? Friend, I honestly don't know. But it must be important, or Ford wouldn't have wasted money and engineering effort putting it in, and no, you can't just hack it all out and throw in a reg'lar gauge. (The computer needs this data to compute a lot of things. If you deny it, it will get pissy with you).

Why did I need to hear all that?

Because. The intuitive shadetree will realize that there are a lot of places for a problem to pop up, and you just can't go at it with a voltmeter and a cheat wire anymore to diagnose it.

How do we diagnose a gauge issue?

Well, if a gauge sticks at one end or another, that's one set of issues. If it swings, seemingly random, that's a much tougher fish to fry.

In my case, suddenly, one day, it just picked a level, and stayed there. I KNEW I wasn’t getting that good of a gas mileage.

The service DVD says the first test is to plug your worldwide data system up, and command the dash to display full, 3/4, 1/2. 1/4, and empty. Don't have one? Not a problem. Starting at KOEO (key off, engine off), hold your setup and reset buttons, and turn the ignition key to RUN (where it lands after you start the car.)

You should see test in the message display. Hit setup once, and you should get GAGE SWEEP. If the gas needle sweeps, it is likely that the instrument cluster is ok.

The next test Ford recommends requires a special Rotunda tool. You can fake it with a couple of resistors, though. All you are doing is substituting a known resistance further and further downstream from the cluster to verify that its' not a bad wire or connector, or, that the cluster is messed up.

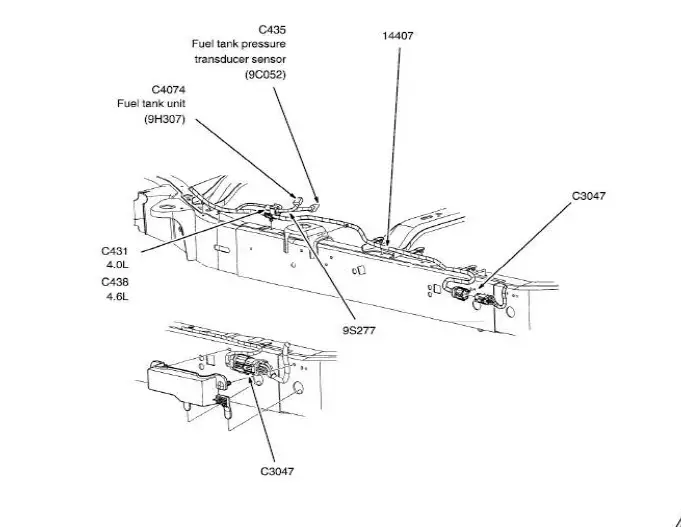

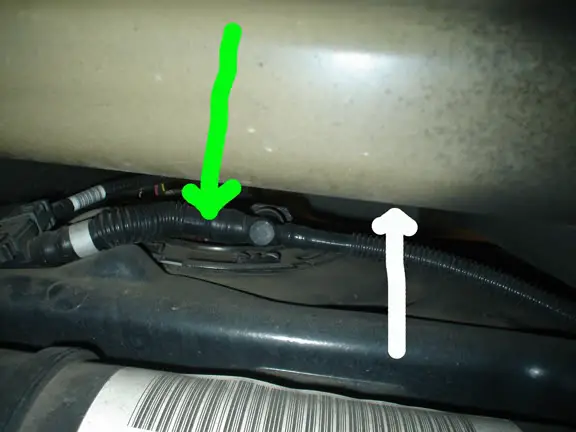

I didn't do any of that. I unplugged a connector (C4037) while the car was on RUN, but not started, because I am fearless.This connector is located under a dust cover on the passenger side, and is trivial to locate:

When I unplugged it, the needle dropped to zero. Plugging it back in, I got the previous readings. If my needle had stayed put through all of that, I would bet that it was somewhere between that connector and the needle, and NOT in the tank.

In my case, it pointed to the 3/4 mark. Now, I never fill this thing all the way up, so I knew it was wrong. Watching the trip meter, either I was getting the best mileage of my life, or the float was stuck. So, I ran it off road, to shake it loose. No dice. I got up under there, and hit the tank (dang, that is a BIG tank) with a mallet.

To spite me, now the gauge pointed straight up like I fed it viagra.

Oh crap, I gotta drop the tank!

Now, if you've never had the pleasure of dropping a fuel tank, let me hip you: it suxxors. You really need to be on concrete or asphalt. Flat. You knock ten years of dirt off everything, reach waaaaay up and over the top of the tank where you can't see, and undo the fuel filler hose, and usually a couple of emissions hoses. Not trivial. Then, using a board perched precariously on a rollaround jack, while the car sits on jackstands so you can actually get up under there, you bust loose some straps. Then, as you lower it, using your knees to steady the tank, you pop loose a couple more hoses, and some electrical connectors.

THEN, you put it on the ground, gently. You did drain the tank first, right? Because most of us can time repairs to the same time we run out of gas, right? You can't just put a hose in an explorer tank, there's a basket screen in the filler pipe.

Then, there's putting it back. Did you know that a pinhole about .020 in diameter can set a trouble code on an explorer? Yeah.

I had no interest in any of that. $90/hr at the local dealership; I didn't have any help, my driveway is a gravel incline, and I just didn't feel like bear wrestling a fuel tank almost as long as I am. So, I cut a frigging hole in my floorboard. Yes, I did. The sensitive are kindly requested to look away now.

Here's how:

I recommend usually a few things here. I am going to assume that you have some basic knowledge in a few skillsets; this isn't for a beginner. One thing I usually recommend is to go wash the undercarriage. Especially in the conventional method, knocking road grime off is a HUGE help.

First, yank the passenger seats.

It only takes about ten minutes. Front passenger seat is four bolts. The little covers, if you still have them, just pop off. DON'T forget to unplug the two little electrical connectors (more if you have the special front seat). Back passenger seat is a combination of bolts and nuts. You don't have to take the small seat out or the seat belt latches, just the 60 bench (60/40 split). The fourth bolt is tricky to get to. Use two extensions, slide it towards the rear, then down on top of the bolt, like so:

Next, pop the doorsill cover off. It is stiff, but simply pops loose. Resist the urge to rent a carpet cleaner, pick it up and roll it back and over the center console. You should be here:

Now, whack a hole. I used a saber saw with a homebrew depth guard. (A depth guard is just something you stand the saw on so that you limit how deep the blade travels. You only need about a 1/4 inch. Any deeper and you run the risk of accidentally whacking a cable or hose. )

This is how much room you got to work with under there:

White is the floor pan, the other is the top of the tank unit.

I just SLOWLY drilled a start hole, cut three corners and bent it back.

I took time, and cleaned the top. No sense in having something fall into the tank.

Now, here is where you can benefit from my next 90 tortured minutes.

First, there are four connectors that bother you. First, pull the vent. This is a *****. Use a couple of screwdrivers. There are red tabs, one on each side. They press inward, then up. Then grab the top red bar with a pair of pliers and yank up. This will release it from the tank vent tit. Now, trace that hose to the tee, then to the right. You'll see a grey electrical connector. push down on the top, and pull the plug. NOW, move that stupid pipe. It is in the way of the gas line.

The gas line is removed by a similar clip. Unlike the vent, that is removed by pulling up, this clip goes to the left, after you unclip the piece on the right. You may need to twist the connector a bit to let the red piece pull out far enough to disengage the clip. (If you don't, it ain't comin' off. I promise).

Once all the hoselry has been moved, now it’s time to remove the assembly. The assembly is held in place by a metal ring, which in turn is secured by several teeth. These teeth do a good job by themselves, but to add insult to injury they are bent over to lock the ring in place.

I tried to be dainty about it, but as the hammer and big screwdriver in the pictures show, eventually, after you skin the knuckles, and the sun is dimming, you do what you need to do. Bend those tabs, then knock the **** out of that lock ring. It will go.

FINALLY

At this point, the fuel unit will come out by pulling straight up, but take care; the fuel float will need a little contorting to get it out of the hole. Also, uh, hey – that’s gas in your crew compartment. Try not to spill any; its’ gonna stink everything up.

Once the unit is out, plug the hole with a towel. Also, if you’ll look straight down, you’ll see what almost looks like a deepwell in the base of the tank. If there is any crap down there, figure out a way to scoop it out. That’s junk waiting to clog your filter up.

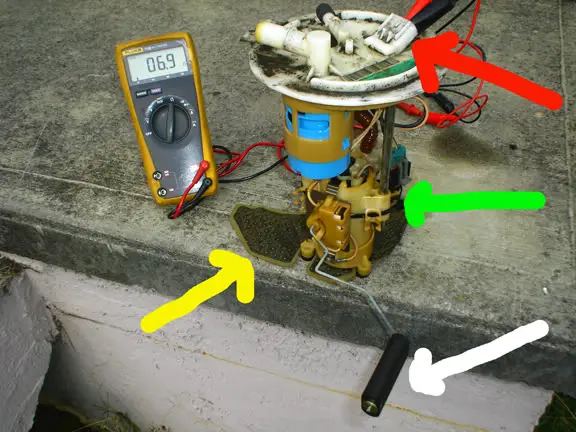

This is the fuel assembly in all its’ glory:

The green arrow points to the pump. The yellow arrow points to part of the sock, a filter that protects the pump. It pops off, and a cleaning in fresh gas isn’t a bad idea at all. The red arrow points to the connector that makes up the fuel level sender circuit; the alligator clips are tying the meter into the circuit. The white arrow points to the float. Following the coat hanger / float wire up, you’ll find the sending unit. It’s basically held in place with a screw and some clips. Clips are FRAGILE, so don’t force things.

Before I cracked it open, I wiggled the arm. It was sloppy, and the meter showed that there was a couple of places that the sender didn’t send a value at all.

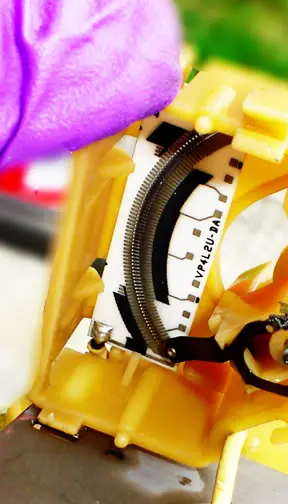

This is the sender unit. See the black arc? That’s a resistor, like in our volume knob. In my case, it’s dirty as hell, and begged for a light scrubbing with a brass brush and some contact cleaner.

Here’s a closeup:

I then cleaned the wiper (the piece that attaches to the float arm, and varies the resistance) and bent it a little more so make sure it would make great contact.

Once I cleaned it (because they won’t sell you just that part – I checked), I reassembled it and tested it by slowly moving the arm. The meter dutifully displayed that I fixed it. No flat spots!

I’d like to share some detail on reassembly, but there’s nothing Earth shattering here. I bent the metal back down, used some high dollar aluminum tape to tape it in place, shoved the carpet back, the seats back, and its’ been months now, and I don’t smell gas or exhaust, and the gauge works like a champ!!

Shawn

Difficulty: Above Average, for two reasons; 1) you wind up cutting a permanent, gaping hole into your car, and 2) you're dealing with gasoline and critical systems. If you have access to the tools, the time, and can follow this, you can do this.

Tools: saber saw with metal blade, screwdrivers, socket set (I forget which specifically, sry) with extensions, volt-ohm meter

Next, a word about gasoline

Too many people have gotten weird ideas about how gasoline behaves. Mostly from 'friend-of-a-friend' stories, and a LOT from Hollywood. See, real life is too boring for movie crews, so, they have to spice things up often. This is why every car, even with minor damage, makes the huge BOOM, and the cool fireball (except the hero car, which can be shot completely up, rammed, and jump through the air, but not even shift funny, but I digress).

The primary danger with gas is what nerds call the vapor phase. The liquid is surprisingly stable. I have seen many, many times where stuff shoulda caused the BOOM, not cause it. On the other hand, when the vapor comes out, that’s when Mister Gas Quits Being Reasonable and starts being the animal it really is.

What does this mean to you? Many people don't mess with certain repairs, because They Fear The BOOM. As long as you follow a few rules, you'll be fine. First, if you get a puddle or a spill, stop what you're doing and clean it up. Second, have lots of fresh ventilation. Third, avoid working on the car when the exhaust is hot. And, if you pull the pump, put something over the hole while its' gone. Past that, as long as you aren't carrying static, or making sparks, you should be fine.

And, if you don't believe me, then why are most fuel tanks made out of plastic now, instead of metal? And, why aren't there more explosions at filling stations?

BEFORE YOU BEGIN!

Listen to me. Seriously. This isn't the normal car you're used to. It is a rolling computer, and it is so, so, SO sensitive to battery shape. BEFORE you waste days going through all this other crap, go check yer battery. If it is a few volts shy at rest, try charging it with a real charger (your alternator won’t suffice), or replace it. If it drops below 10v while cranking, replace it. Period. If the terminals are a little crapped up, FIX THEM. No green, no dirt, clean and tight. Don't hesitate to whack a terminal connector off and replace them. SERIOUSLY.

There are a TON of gremlins and transient issues that can only be solved with a good battery. I don't care if its' 6 months or 6 years old. Don't assume your battery is good. I promise.

OK - a backgrounder on this retarded/genius gas system

In my first car, here is how it worked-

In the fuel tank is a float. This float is connected by an arm to for all intents and purposes, a volume knob. As the level of fuel rises, the float also rises, and turns the knob one way. As it drops, the knob turns the other way. The knob is actually a variable resistor, and turning it changes the value of resistance.

You put electricity through it, and attach a voltmeter to the other side, and voila! Gas Gauge!

Well, in the flex fuel Ford, there are a number of complications.

First, for some reason unknown to me, Ford thinks sending direct current through the fuel sensor in a tank full of ethanol is a bad idea. (I even researched it, and couldn't come up with anything. I am guessing the alcohol has some kind of electroplating effect on the resistor part over time. Just a guess).

So, in between the wire and the fuel sensor / volume knob, there is a DC to AC converter.

On the other end, we no longer have a simple, analog car. What we have basically is a computer with wheels that can’t understand the volume knob (analog) input.

So, now, at the used-to-be-dashboard-now-we-call-it-an-instrument-cluster, there is an analog-to-digital converter. Continuously variable voltage goes in one side, a digital signal that is a binary number proportionate to the amount of fuel in the tank comes out the other side.

But wait, there's more!

See, the master computer what runs everything in the car doesn't like the fact that as the car moves, the float is continuously in motion and therefore continuously sending varying data to the computer and the cluster. Nope. So, it has a computer program that interprets the data it is seeing, and compares it with information from other sensors and timers, and THEN, sends a signal to the little needle telling you its' time to feed the hog again.

So, if you’re keeping count, it goes sender > harness with connectors > digital to analog converter > computer > fuel gauge

Seriously! There are 3-4 fuel gauge programs or 'strategies' that the car is continuously running.

The first one, is called 'Anti-Slosh Mode'. You are normally in this mode. Basically, the system averages the readings it sees over time then adjusts the needle to match. Unless you're standing still, and not sloshing, you really aren't seeing the true tank level.

The second and third (and maybe fourth, I forget now) strategies kick in when there's been a gap in the continuous data, or there's been a large change in the data.

IF THE KEY WAS OFF, and there has been a large change in the current data (in other words, you put at least 15% more gas in it than it had) from the stored value, there is a small delay where the needle does nothing while the computer averages things. Then, it reverts back to antislosh.

IF THE KEY WAS ON, oh boy. You just invoked a series of timers, that unless defeated by turning the car off for a period of time, can wait up to 55 MINUTES to watch the system settle before adjusting the needle. This isn't an error, it is a factory programmed strategy.

The last strategy is similar to key on / data change, and it gets invoked if there was a gap in data, like an intermittent short, or bus error or something.

In simpler words, refuel with the car off; your gauge will be pretty accurate (everything else notwithstanding). Refuel with the car on, and it will take foooorever to reflect the new level.

Why does it need all this? Friend, I honestly don't know. But it must be important, or Ford wouldn't have wasted money and engineering effort putting it in, and no, you can't just hack it all out and throw in a reg'lar gauge. (The computer needs this data to compute a lot of things. If you deny it, it will get pissy with you).

Why did I need to hear all that?

Because. The intuitive shadetree will realize that there are a lot of places for a problem to pop up, and you just can't go at it with a voltmeter and a cheat wire anymore to diagnose it.

How do we diagnose a gauge issue?

Well, if a gauge sticks at one end or another, that's one set of issues. If it swings, seemingly random, that's a much tougher fish to fry.

In my case, suddenly, one day, it just picked a level, and stayed there. I KNEW I wasn’t getting that good of a gas mileage.

The service DVD says the first test is to plug your worldwide data system up, and command the dash to display full, 3/4, 1/2. 1/4, and empty. Don't have one? Not a problem. Starting at KOEO (key off, engine off), hold your setup and reset buttons, and turn the ignition key to RUN (where it lands after you start the car.)

You should see test in the message display. Hit setup once, and you should get GAGE SWEEP. If the gas needle sweeps, it is likely that the instrument cluster is ok.

The next test Ford recommends requires a special Rotunda tool. You can fake it with a couple of resistors, though. All you are doing is substituting a known resistance further and further downstream from the cluster to verify that its' not a bad wire or connector, or, that the cluster is messed up.

I didn't do any of that. I unplugged a connector (C4037) while the car was on RUN, but not started, because I am fearless.This connector is located under a dust cover on the passenger side, and is trivial to locate:

When I unplugged it, the needle dropped to zero. Plugging it back in, I got the previous readings. If my needle had stayed put through all of that, I would bet that it was somewhere between that connector and the needle, and NOT in the tank.

In my case, it pointed to the 3/4 mark. Now, I never fill this thing all the way up, so I knew it was wrong. Watching the trip meter, either I was getting the best mileage of my life, or the float was stuck. So, I ran it off road, to shake it loose. No dice. I got up under there, and hit the tank (dang, that is a BIG tank) with a mallet.

To spite me, now the gauge pointed straight up like I fed it viagra.

Oh crap, I gotta drop the tank!

Now, if you've never had the pleasure of dropping a fuel tank, let me hip you: it suxxors. You really need to be on concrete or asphalt. Flat. You knock ten years of dirt off everything, reach waaaaay up and over the top of the tank where you can't see, and undo the fuel filler hose, and usually a couple of emissions hoses. Not trivial. Then, using a board perched precariously on a rollaround jack, while the car sits on jackstands so you can actually get up under there, you bust loose some straps. Then, as you lower it, using your knees to steady the tank, you pop loose a couple more hoses, and some electrical connectors.

THEN, you put it on the ground, gently. You did drain the tank first, right? Because most of us can time repairs to the same time we run out of gas, right? You can't just put a hose in an explorer tank, there's a basket screen in the filler pipe.

Then, there's putting it back. Did you know that a pinhole about .020 in diameter can set a trouble code on an explorer? Yeah.

I had no interest in any of that. $90/hr at the local dealership; I didn't have any help, my driveway is a gravel incline, and I just didn't feel like bear wrestling a fuel tank almost as long as I am. So, I cut a frigging hole in my floorboard. Yes, I did. The sensitive are kindly requested to look away now.

Here's how:

I recommend usually a few things here. I am going to assume that you have some basic knowledge in a few skillsets; this isn't for a beginner. One thing I usually recommend is to go wash the undercarriage. Especially in the conventional method, knocking road grime off is a HUGE help.

First, yank the passenger seats.

It only takes about ten minutes. Front passenger seat is four bolts. The little covers, if you still have them, just pop off. DON'T forget to unplug the two little electrical connectors (more if you have the special front seat). Back passenger seat is a combination of bolts and nuts. You don't have to take the small seat out or the seat belt latches, just the 60 bench (60/40 split). The fourth bolt is tricky to get to. Use two extensions, slide it towards the rear, then down on top of the bolt, like so:

Next, pop the doorsill cover off. It is stiff, but simply pops loose. Resist the urge to rent a carpet cleaner, pick it up and roll it back and over the center console. You should be here:

Now, whack a hole. I used a saber saw with a homebrew depth guard. (A depth guard is just something you stand the saw on so that you limit how deep the blade travels. You only need about a 1/4 inch. Any deeper and you run the risk of accidentally whacking a cable or hose. )

This is how much room you got to work with under there:

White is the floor pan, the other is the top of the tank unit.

I just SLOWLY drilled a start hole, cut three corners and bent it back.

I took time, and cleaned the top. No sense in having something fall into the tank.

Now, here is where you can benefit from my next 90 tortured minutes.

First, there are four connectors that bother you. First, pull the vent. This is a *****. Use a couple of screwdrivers. There are red tabs, one on each side. They press inward, then up. Then grab the top red bar with a pair of pliers and yank up. This will release it from the tank vent tit. Now, trace that hose to the tee, then to the right. You'll see a grey electrical connector. push down on the top, and pull the plug. NOW, move that stupid pipe. It is in the way of the gas line.

The gas line is removed by a similar clip. Unlike the vent, that is removed by pulling up, this clip goes to the left, after you unclip the piece on the right. You may need to twist the connector a bit to let the red piece pull out far enough to disengage the clip. (If you don't, it ain't comin' off. I promise).

Once all the hoselry has been moved, now it’s time to remove the assembly. The assembly is held in place by a metal ring, which in turn is secured by several teeth. These teeth do a good job by themselves, but to add insult to injury they are bent over to lock the ring in place.

I tried to be dainty about it, but as the hammer and big screwdriver in the pictures show, eventually, after you skin the knuckles, and the sun is dimming, you do what you need to do. Bend those tabs, then knock the **** out of that lock ring. It will go.

FINALLY

At this point, the fuel unit will come out by pulling straight up, but take care; the fuel float will need a little contorting to get it out of the hole. Also, uh, hey – that’s gas in your crew compartment. Try not to spill any; its’ gonna stink everything up.

Once the unit is out, plug the hole with a towel. Also, if you’ll look straight down, you’ll see what almost looks like a deepwell in the base of the tank. If there is any crap down there, figure out a way to scoop it out. That’s junk waiting to clog your filter up.

This is the fuel assembly in all its’ glory:

The green arrow points to the pump. The yellow arrow points to part of the sock, a filter that protects the pump. It pops off, and a cleaning in fresh gas isn’t a bad idea at all. The red arrow points to the connector that makes up the fuel level sender circuit; the alligator clips are tying the meter into the circuit. The white arrow points to the float. Following the coat hanger / float wire up, you’ll find the sending unit. It’s basically held in place with a screw and some clips. Clips are FRAGILE, so don’t force things.

Before I cracked it open, I wiggled the arm. It was sloppy, and the meter showed that there was a couple of places that the sender didn’t send a value at all.

This is the sender unit. See the black arc? That’s a resistor, like in our volume knob. In my case, it’s dirty as hell, and begged for a light scrubbing with a brass brush and some contact cleaner.

Here’s a closeup:

I then cleaned the wiper (the piece that attaches to the float arm, and varies the resistance) and bent it a little more so make sure it would make great contact.

Once I cleaned it (because they won’t sell you just that part – I checked), I reassembled it and tested it by slowly moving the arm. The meter dutifully displayed that I fixed it. No flat spots!

I’d like to share some detail on reassembly, but there’s nothing Earth shattering here. I bent the metal back down, used some high dollar aluminum tape to tape it in place, shoved the carpet back, the seats back, and its’ been months now, and I don’t smell gas or exhaust, and the gauge works like a champ!!

Shawn