ANTHONY-GATLIN

Active Member

- Joined

- August 3, 2012

- Messages

- 96

- Reaction score

- 2

- City, State

- TOKYO

- Year, Model & Trim Level

- 2005 FORD-EXPLORER SPORTS

nice just keep the photos coming

I know this list is old but I was thinking about doing this to my 4.6l 2002 Explorer. You said you were going to post pictures of what you needed but I don’t see any. Would you be willing to post them or I can give you my email if you would be willing to send directly if that is easierHi guys- I'm new to your forum, and I have some questions.

I have a 2002 Explorer Limited, V8 4.6 litre 4X4 and I love it, but the ATX transmission is toast. I never did like auto's, and would rather modify this once to accept a manual transmission and keep the 4X4. I have searched a bunch of info, but I am not sure if this has been successfully done by anyone here to know if it is in fact do-able.

The last post I've found that seems close is below:

According to what I have been able to find out so far:

Code:macknos94 05-29-2010 Here is what you will need to swap in a manual tranny with the 4x4 t case. Tranny and slave out of 97 body style 4.6 f150 along with a manual t case from the same style truck. Clutch peddle out of 3rd gen along with the master. Then the hydro line can come from any manual 3rd gen ex. As for the clutch and flywheel you just need one for a 4.6 f150. Last but not least a tune to cut out the electric tranny and t case stuff. It's a straight forward swap and you won't have to do much cutting besides the shift and t case shifter. As for the drive shaft length I haven't gotten that far but they should be the right length.

Can't remember who posted this in another thread, but I copied it for reference. (apologies to O/P)

I've looked up on transmission info and found the following trans ID codes regarding the M5R2 transmissions for 4 wheel drive applications:

f150 '97-'98

F65A-BD

F75A-DA

F85A-DA

f150 '99-2000

XL34-ZB

XL34-ZC

f250 '97-'98

F65A-FD

F75A-DA

F85A-DA

f250 1999

XL-34-ZB

XL34-ZC

1. Will any or all of these work (ie; direct bolt up to bellhousing, input output shaft splines compatible, transfer case etc?)

2. Does anyone know what the differences are between the years, or between f150 vs. f250? (ie:Are there differences in bellhousing, input or output shafts, or gear ratios?)

3. Can I still use the electronic t-case from my truck? (Would prefer this, for costs, and cleanliness inside cabin, though I'm not opposed to doing fabrication or modification work- These posts talk about the manual transfer case from the f150.)

4. can the ECU simply be flashed to tell it to ignore the (lack of) input from the missing 5R55S (I think that's the ATX that's in it now)?

I don't need heavy duty, my Explorer is a daily driver, don't tow often and don't do much off road- I'm just trying to see which options might work, so I can broaden my search, maybe find a lower mileage transmission, and hopefully save money. (Or based on the differences, if all of these would work, is one of these better for a daily driver?

Thanks in advance- would love to have her fixed and back on the road with three footpedals! (I'm not including the e-brake!)

Dave

Edit March, 2016

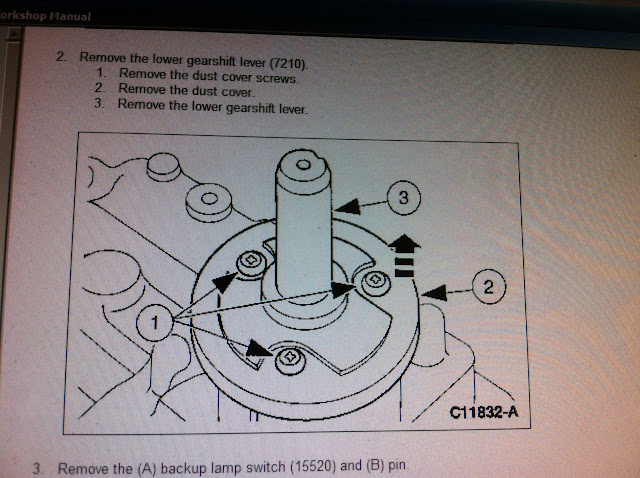

View attachment 325080

Sorry for the delay in posting- but this DID get completed!

For those of you who are interested in how this was done- read on. I am going to post up my pictures of what I needed to do to complete this swap.

Just so you know if you click on people’s accounts you can see when they were last seen and Op was last seen in around august 2019 so I don’t think you’ll be getting an answer from him anytime soonI know this list is old but I was thinking about doing this to my 4.6l 2002 Explorer. You said you were going to post pictures of what you needed but I don’t see any. Would you be willing to post them or I can give you my email if you would be willing to send directly if that is easier

iirc OP does have some pics, but theyre duplicated. try letting rick know in the suggestions subforum, there should be a stickyUsing this thread as a guide for when I do this... anyone else other than OP try this?

thanks. wish i could contact OP for all the build info, would make life a lot easier loliirc OP does have some pics, but theyre duplicated. try letting rick know in the suggestions subforum, there should be a sticky

yep! hopefully rick sees that and fixes the picsthanks. wish i could contact OP for all the build info, would make life a lot easier lol

rick is adminwhere do i contact rick again, or is rick the OP? sorry for sounding dumb