domct203

Pilots The Beast

- Joined

- October 11, 2017

- Messages

- 581

- Reaction score

- 173

- City, State

- CT

- Year, Model & Trim Level

- 2002 Explorer XLS

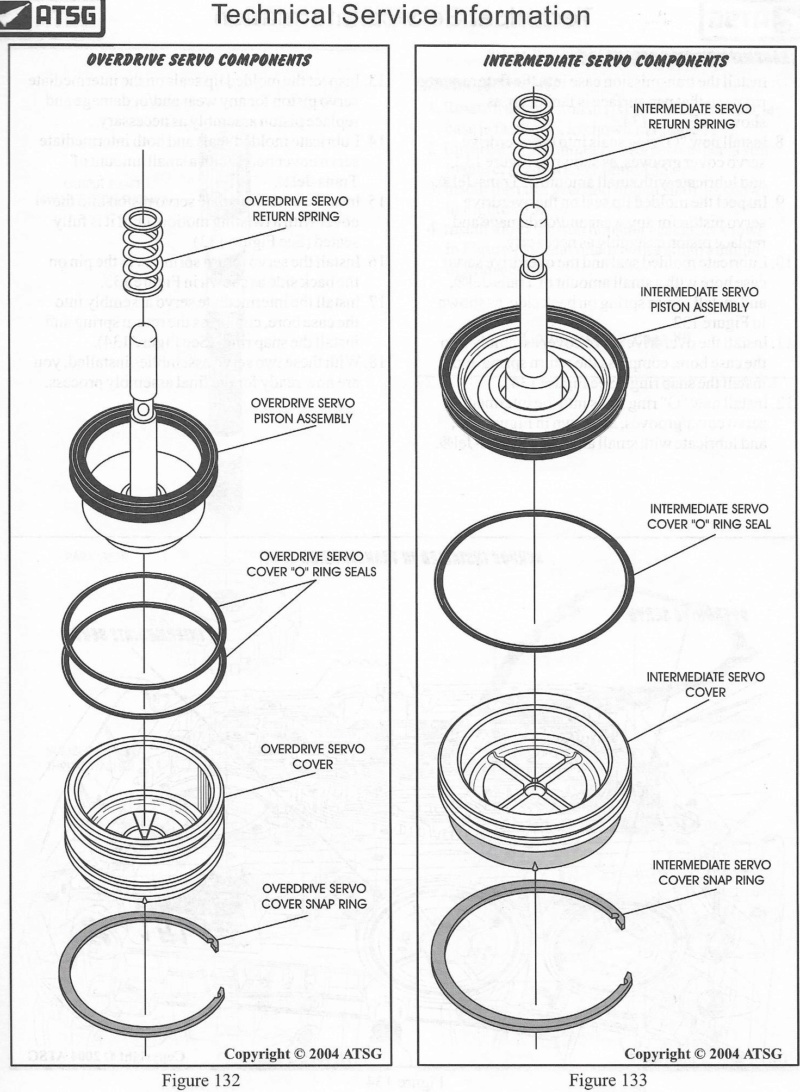

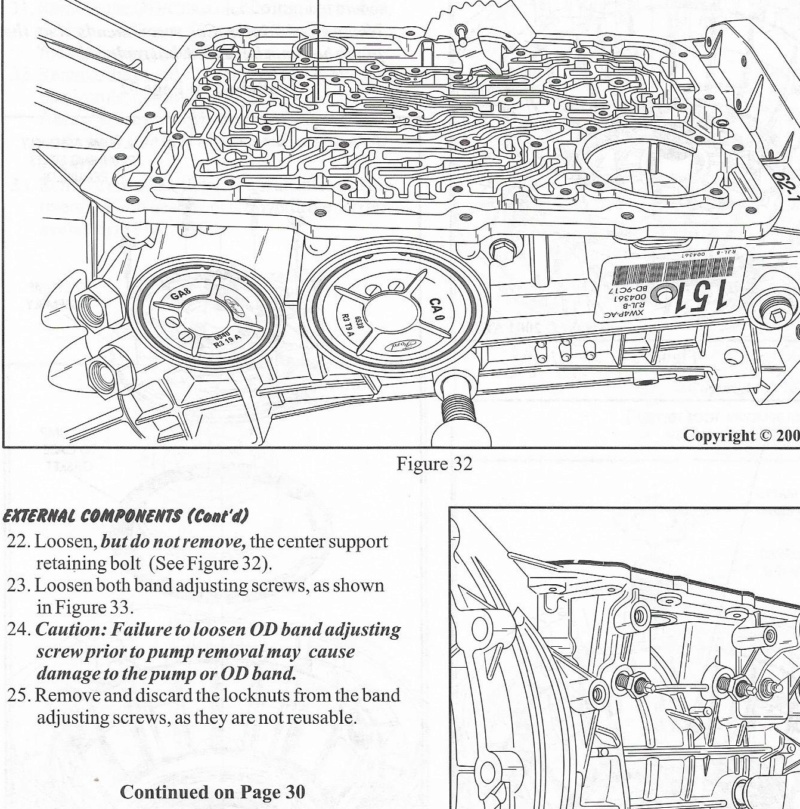

Progress, I got the cover off using some oil filter locking pliers I bought for the body lift. I found that the piston rod has broken away from the cylinder head right where it is swedged together.

Now if I put just the piston rod through the case until I feel it push against the band, I feel a very slight wiggle to the bore by a few thousands of an inch. It is wobbly, but not terrible at all.

Should this be a friction fit with pretty much no wiggle?

With that said, should I just go with the modified replacement?

Now if I put just the piston rod through the case until I feel it push against the band, I feel a very slight wiggle to the bore by a few thousands of an inch. It is wobbly, but not terrible at all.

Should this be a friction fit with pretty much no wiggle?

With that said, should I just go with the modified replacement?