- Joined

- March 16, 2013

- Messages

- 4,261

- Reaction score

- 233

- City, State

- Woodstock, GA

- Year, Model & Trim Level

- 04 Ford Explorer 4.6l

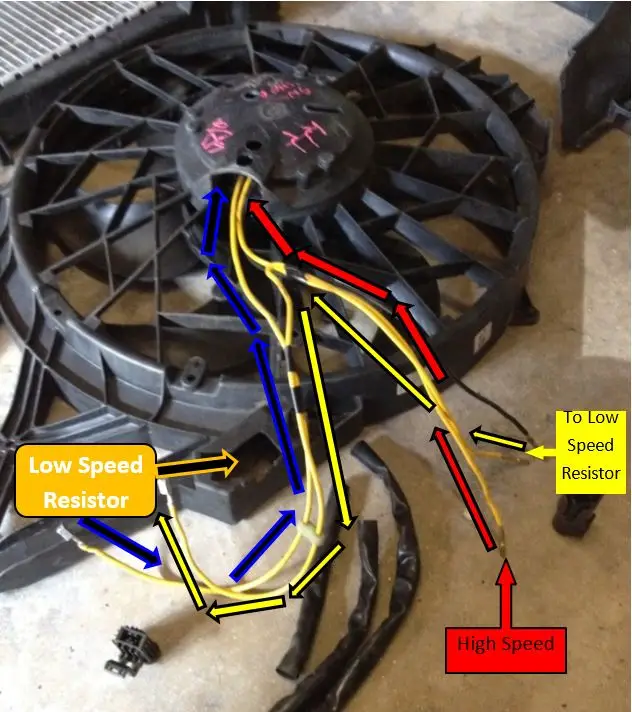

I thought I'd post the information on my e-fan install for my 3rd gen 2004 Explorer with the 4.6l V8. I did this in March of 2014 I think, I really don't recall anymore. Unfortunately, I've lost some notes as well. So it'll mostly be pictures. A lot of pictures, so it may not view well on your phone.

I didn't land a Mark VIII fan and frankly I'm glad I didn't. I did get a fan off a Lincoln town car or something that had the 4.6l. It had an inrush well over the limits of my gauge (100+ amps) and I couldn't find a way to limit the inrush. I ended up with a fan out of a 2001 Mustang GT. The Mustangs inrush was just under 60 amps IIRC and ran at just under 20. If the fan was good enough for the 4.6 in the Mustang, I figured it had to work good for me. My Ex runs at 195 with the fan going (when needed.) On the hottest day in Atlanta, in the bumper to bumper traffic, the temp reached 212.

Mustang fan.

My cuts to the fan.

How the fan will set in the fan shroud.

Fabricated brackets to hold the upper portion of the fan in place. If I wasn't so lazy, I'd take these to someone and have them fabricate solid pieces. If I did that though, the fan still wouldn't be installed.

I didn't land a Mark VIII fan and frankly I'm glad I didn't. I did get a fan off a Lincoln town car or something that had the 4.6l. It had an inrush well over the limits of my gauge (100+ amps) and I couldn't find a way to limit the inrush. I ended up with a fan out of a 2001 Mustang GT. The Mustangs inrush was just under 60 amps IIRC and ran at just under 20. If the fan was good enough for the 4.6 in the Mustang, I figured it had to work good for me. My Ex runs at 195 with the fan going (when needed.) On the hottest day in Atlanta, in the bumper to bumper traffic, the temp reached 212.

Mustang fan.

My cuts to the fan.

How the fan will set in the fan shroud.

Fabricated brackets to hold the upper portion of the fan in place. If I wasn't so lazy, I'd take these to someone and have them fabricate solid pieces. If I did that though, the fan still wouldn't be installed.