Performance Upgrades - Maintenance - Modifications - Problem Solving - Off-Road - Street Trucks.

Register Today

JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an

alternative browser .

BrooklynBay Media item

October 16, 2013

armband

back

of

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 16, 2013

a

armband

in

is

multimeter

the

Comments: 0

Category: General Photo Album

This is a side by comparison between the socket holes on two Aerostar taillights.

BrooklynBay Media item

September 4, 2013

1995

1996

aerostar

and

is

left

on

right

taillight

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

September 3, 2013

finished

is

left

on

product.

taillight

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

September 3, 2013

be

cut

foam

has

insulation

the

to

Comments: 0

Category: General Photo Album

BrooklynBay Media item

September 3, 2013

cut

light

template

the

to

use

Comments: 0

Category: General Photo Album

BrooklynBay Media item

September 3, 2013

a

cut

from

is

made

taillight

template

the

Comments: 0

Category: General Photo Album

This is a sliding door latch modification to prevent it from jamming.

BrooklynBay Media item

February 24, 2013

bracket.

go

has

hole

in

into

spring

the

to

Comments: 0

Category: General Photo Album

BrooklynBay Media item

November 29, 2012

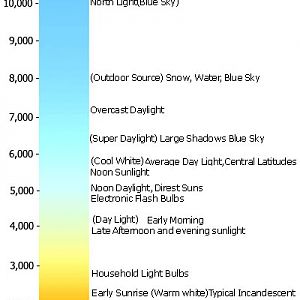

color

in

kelvin

scale

temperatures

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

of

old

shock

the

top

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

new

of

shock

the

top

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

cracker

nut

the

worked

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

are

curved

holding

pliers

stud

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

bottom

of

old

shock

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

bottom

new

of

shock

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

cracked

of

off

part

shock

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

box

over

pipe

pvc

the

wrench

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

hold

if

in

inner

it

nut

place

the

turns

Comments: 0

Category: General Photo Album

BrooklynBay Media item

October 10, 2012

a

floor

into

jack

place

pushes

shock

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

July 19, 2012

into

is

seams

sprayed

the

water

Comments: 0

Category: General Photo Album

BrooklynBay Media item

July 19, 2012

align

properly

spacers

the

tile

tiles

to

use

Comments: 0

Category: General Photo Album

BrooklynBay Media item

July 19, 2012

are

but

grout

installed

need

the

tiles

Comments: 0

Category: General Photo Album

BrooklynBay Media item

July 19, 2012

are

grouted

the

tiles

Comments: 0

Category: General Photo Album

BrooklynBay Media item

July 19, 2012

are

seams

taped

the

Comments: 0

Category: General Photo Album

BrooklynBay Media item

July 19, 2012

an

attachment

cutter

is

the

Comments: 0

Category: General Photo Album