fulfilledstraw

Member

- Joined

- May 12, 2007

- Messages

- 46

- Reaction score

- 0

- City, State

- Georgia

- Year, Model & Trim Level

- '92 Explorer XLT

Hello all,

In my efforts to track down the cause of an annoying clicking noise coming from my front end, I addressed many possible causes on the front end of my '92 XLT 4X4. I started simple; I replaced the anti-rattle clips of my brake pads, or really just checked to see if they were indeed there (they were). With no luck, I then went on and checked my wheel bearings and repacked them to make doubly sure that they were not the culprit. Still, no luck. Since the clicking was accompanied by an occasional "clunk" when braking, I went ahead and replaced the radius arm bushings with some after-market Moogs (on my budget, I would consider that overkill). After 7+ hours under my explorer in the rain (don't ask), I assumed that my efforts would be rewarded by the sweet sound of anything but that damned clicking noise that was, at this point, driving me insane. Despite these efforts, the problem remained unsolved. It was only yesterday that I had the time to fix what I concluded could be the only remaining problem, my upper and lower balljoints. 8 hours later and, voila! No more clicking noise.

Now, I write this much in the hopes that someone else can relate to my situation. I searched these forums high and low for a 1st gen balljoint walk through with no luck, though I did stumble across a few pics that gave me an idea of how to do this repair. A friend assisted me with the repair, and I took the opportunity to document the important parts of it as best I can for all of you 1st gen owners that learn visually, or who simply want to get an idea of what this job entails.

I'll start by saying that you should rent a ball joint press from Autozone or a parts store, unless you want to take your steering knuckle to a shop to have them press the balljoints out. Additionally, I put my new balljoints in the freezer overnight, and that really made the job easier. I consulted the Haynes manual when I got stuck; it had useful information in it like torque specs and other notes. I'd recommend having some sort of repair manual handy regardless.

I am not an expert mechanic; if there is indeed a by-the-book method of doing this, I probably deviated from that at some point. This is how I did the job, and I hope that it is a helpful reference for others.

To begin, put the front end on jack stands, remove the tire, and remove the hub assembly, caliper, and rotor. Glacier's awesome 1st gen brake tutorial shows you how to do all of that here.

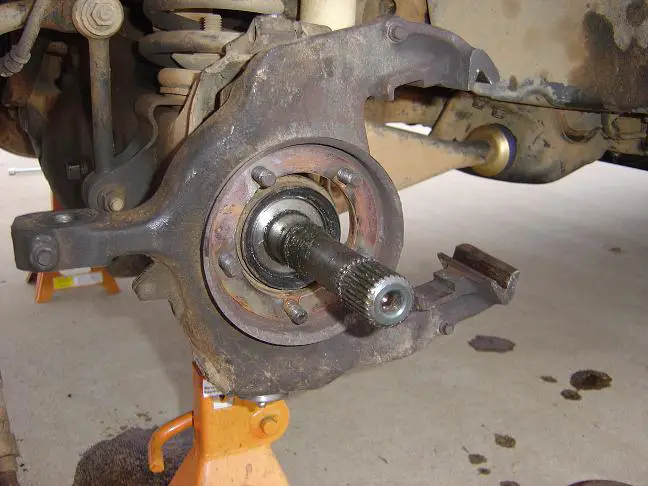

We then removed the spindle and spindle seat. The picture below shows the spindle removed and the axleshaft sticking out. If you look to the left, you'll also see that we have already removed the tie rod by removing the cotter pin and unscrewing the bottom nut. It should pop right out.

We then pulled out the axleshaft, which wasn't difficult on the drivers side. We had to remove the rubber boot to get the passenger side axleshaft out. I didn't get a picture of the boot, but you'll see what I mean when you try to pull it out and it won't go. The driver's side axleshaft is pictured below, alongside the spindle. A bit of differential fluid drained out when we pulled it, so I took the opportunity to pump the rest out and change it.

Now go ahead and assume that you're going to need a front end alignment after this repair, but you'll still want to make a note of the position of the camber adjustment sleeve that houses the upper ball joint before you remove the steering knuckle. The sleeve is held tight by a clamp that uses funky looking bolt. The bolt is a metric size, though I forget what it was, but more importantly you can remove it with a ratchet. We just drew a line across the sleeve with a magic marker before we removed the steering knuckle.

Of course, we used snap ring pliers to remove the snap ring and then took off the pinch bolt of the upper balljoint, and we completely removed the lower balljoint nut, though the manual says to loosen it only to the end of the stud so as to prevent the steering knuckle from falling all after you knock it out.

After making our marks, we hammered out the steering knuckle with, well, a hammer. The whole assembly came loose with ample persuasion, and this is what it looks like. Now don't get confused, as I actually took this picture after we had pressed the new balljoints into the steering knuckle. The old ones can be seen on the upper right.

Removing the ball joints would have been impossible without a ball joint press, which we rented from Autozone for $99. I know other threads have shown this tool, which is basically a large C-clamp with several adapters. The picture below shows the the removal process, with the lower balljoint already removed.

I said before that you should put your new balljoints in the freezer overnight to aid in the pressing process. Also, a large breaker ball or some sort of lever will make it easier, as we discovered. Here is a picture of the installation process. We scratched our heads for all of 15 minutes to figure out how to configure all the components correctly, so hopefully you won't have to.

Squeeze them in until they are nice and snug, or until you simply can't press them anymore.

I ordered my new balljoints from rockauto.com (if you haven't heard of them, you are missing out); they are simply repair grade Spicer balljoints that ran about $9 a piece. The lower ball joints don't have a place for a cotter pin, which I found odd, but I figured I ought to mention it.

The lower balljoint nut, when put back in place, should be torqued between 83 and 113 ft/lbs per the Haynes manual. Otherwise, installation is the reverse of removal, and make sure that you can steer the knuckles after you put everything back in place. We also discovered that turning the steering wheel with the Explorer turned off sometimes results in power steering fluid squirting out of the cap, which we found comical yet inconvenient.

I have seen a few questions asking what bad ball joints look like. I had an idea that mine were bad because the rubber boot on them was worn to the point of being able to twist it around freely. No doubt the grease was drained out and a lot of gunk had accrued inside them. The old ones are pictured below.

That's all I can really think of at this point. I have a few more pictures available, but I think that these should suffice. I hope this is helpful to someone, though I am sure that the experts of this forum can fill in the gaps as necessary. Good luck!

In my efforts to track down the cause of an annoying clicking noise coming from my front end, I addressed many possible causes on the front end of my '92 XLT 4X4. I started simple; I replaced the anti-rattle clips of my brake pads, or really just checked to see if they were indeed there (they were). With no luck, I then went on and checked my wheel bearings and repacked them to make doubly sure that they were not the culprit. Still, no luck. Since the clicking was accompanied by an occasional "clunk" when braking, I went ahead and replaced the radius arm bushings with some after-market Moogs (on my budget, I would consider that overkill). After 7+ hours under my explorer in the rain (don't ask), I assumed that my efforts would be rewarded by the sweet sound of anything but that damned clicking noise that was, at this point, driving me insane. Despite these efforts, the problem remained unsolved. It was only yesterday that I had the time to fix what I concluded could be the only remaining problem, my upper and lower balljoints. 8 hours later and, voila! No more clicking noise.

Now, I write this much in the hopes that someone else can relate to my situation. I searched these forums high and low for a 1st gen balljoint walk through with no luck, though I did stumble across a few pics that gave me an idea of how to do this repair. A friend assisted me with the repair, and I took the opportunity to document the important parts of it as best I can for all of you 1st gen owners that learn visually, or who simply want to get an idea of what this job entails.

I'll start by saying that you should rent a ball joint press from Autozone or a parts store, unless you want to take your steering knuckle to a shop to have them press the balljoints out. Additionally, I put my new balljoints in the freezer overnight, and that really made the job easier. I consulted the Haynes manual when I got stuck; it had useful information in it like torque specs and other notes. I'd recommend having some sort of repair manual handy regardless.

I am not an expert mechanic; if there is indeed a by-the-book method of doing this, I probably deviated from that at some point. This is how I did the job, and I hope that it is a helpful reference for others.

To begin, put the front end on jack stands, remove the tire, and remove the hub assembly, caliper, and rotor. Glacier's awesome 1st gen brake tutorial shows you how to do all of that here.

We then removed the spindle and spindle seat. The picture below shows the spindle removed and the axleshaft sticking out. If you look to the left, you'll also see that we have already removed the tie rod by removing the cotter pin and unscrewing the bottom nut. It should pop right out.

We then pulled out the axleshaft, which wasn't difficult on the drivers side. We had to remove the rubber boot to get the passenger side axleshaft out. I didn't get a picture of the boot, but you'll see what I mean when you try to pull it out and it won't go. The driver's side axleshaft is pictured below, alongside the spindle. A bit of differential fluid drained out when we pulled it, so I took the opportunity to pump the rest out and change it.

Now go ahead and assume that you're going to need a front end alignment after this repair, but you'll still want to make a note of the position of the camber adjustment sleeve that houses the upper ball joint before you remove the steering knuckle. The sleeve is held tight by a clamp that uses funky looking bolt. The bolt is a metric size, though I forget what it was, but more importantly you can remove it with a ratchet. We just drew a line across the sleeve with a magic marker before we removed the steering knuckle.

Of course, we used snap ring pliers to remove the snap ring and then took off the pinch bolt of the upper balljoint, and we completely removed the lower balljoint nut, though the manual says to loosen it only to the end of the stud so as to prevent the steering knuckle from falling all after you knock it out.

After making our marks, we hammered out the steering knuckle with, well, a hammer. The whole assembly came loose with ample persuasion, and this is what it looks like. Now don't get confused, as I actually took this picture after we had pressed the new balljoints into the steering knuckle. The old ones can be seen on the upper right.

Removing the ball joints would have been impossible without a ball joint press, which we rented from Autozone for $99. I know other threads have shown this tool, which is basically a large C-clamp with several adapters. The picture below shows the the removal process, with the lower balljoint already removed.

I said before that you should put your new balljoints in the freezer overnight to aid in the pressing process. Also, a large breaker ball or some sort of lever will make it easier, as we discovered. Here is a picture of the installation process. We scratched our heads for all of 15 minutes to figure out how to configure all the components correctly, so hopefully you won't have to.

Squeeze them in until they are nice and snug, or until you simply can't press them anymore.

I ordered my new balljoints from rockauto.com (if you haven't heard of them, you are missing out); they are simply repair grade Spicer balljoints that ran about $9 a piece. The lower ball joints don't have a place for a cotter pin, which I found odd, but I figured I ought to mention it.

The lower balljoint nut, when put back in place, should be torqued between 83 and 113 ft/lbs per the Haynes manual. Otherwise, installation is the reverse of removal, and make sure that you can steer the knuckles after you put everything back in place. We also discovered that turning the steering wheel with the Explorer turned off sometimes results in power steering fluid squirting out of the cap, which we found comical yet inconvenient.

I have seen a few questions asking what bad ball joints look like. I had an idea that mine were bad because the rubber boot on them was worn to the point of being able to twist it around freely. No doubt the grease was drained out and a lot of gunk had accrued inside them. The old ones are pictured below.

That's all I can really think of at this point. I have a few more pictures available, but I think that these should suffice. I hope this is helpful to someone, though I am sure that the experts of this forum can fill in the gaps as necessary. Good luck!